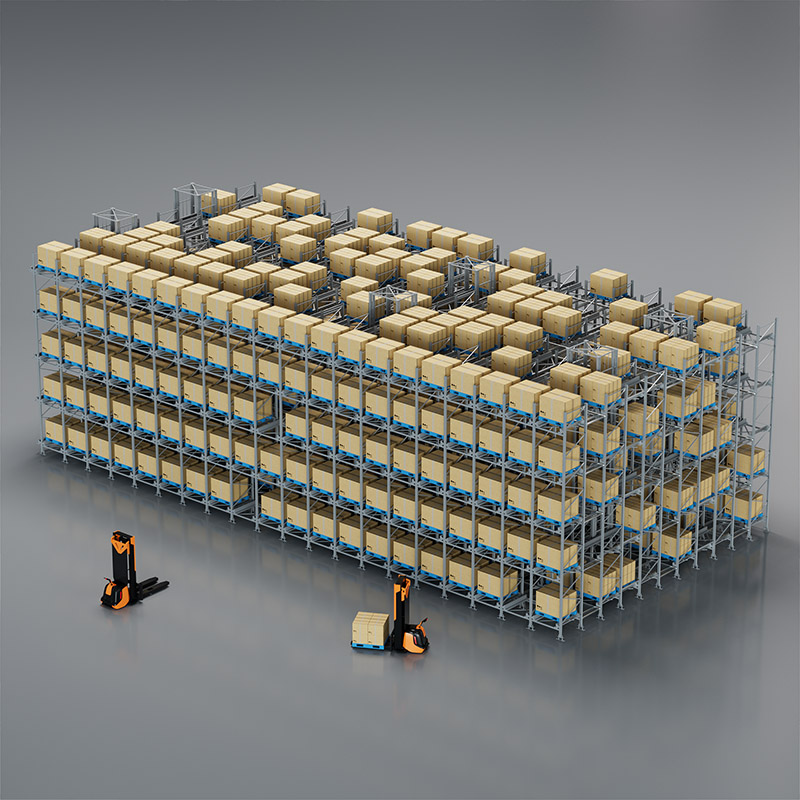

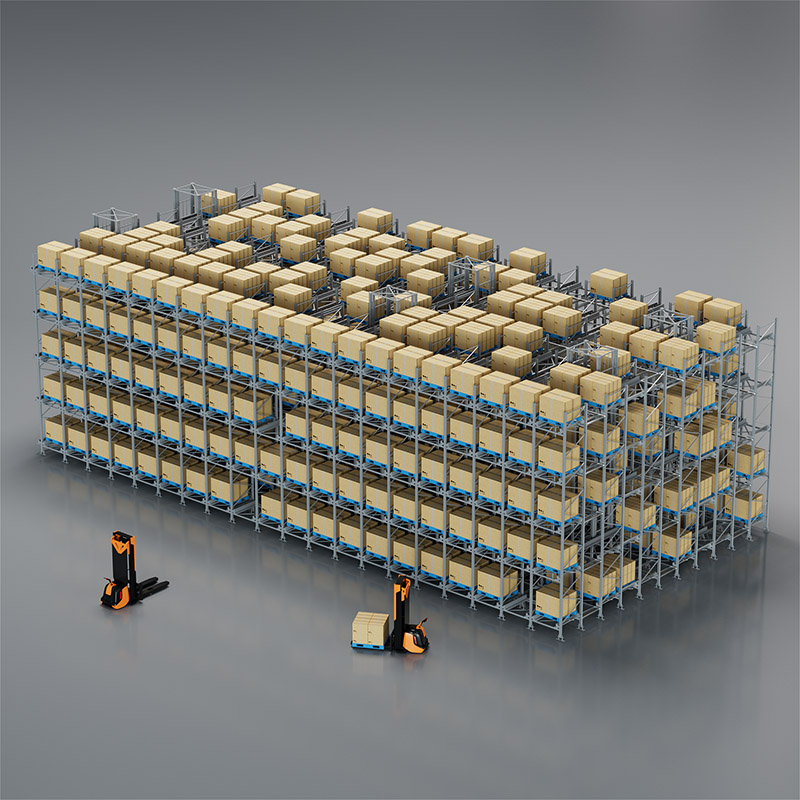

6 Way Pallet Shuttle System for High-Density Smart Warehousing

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

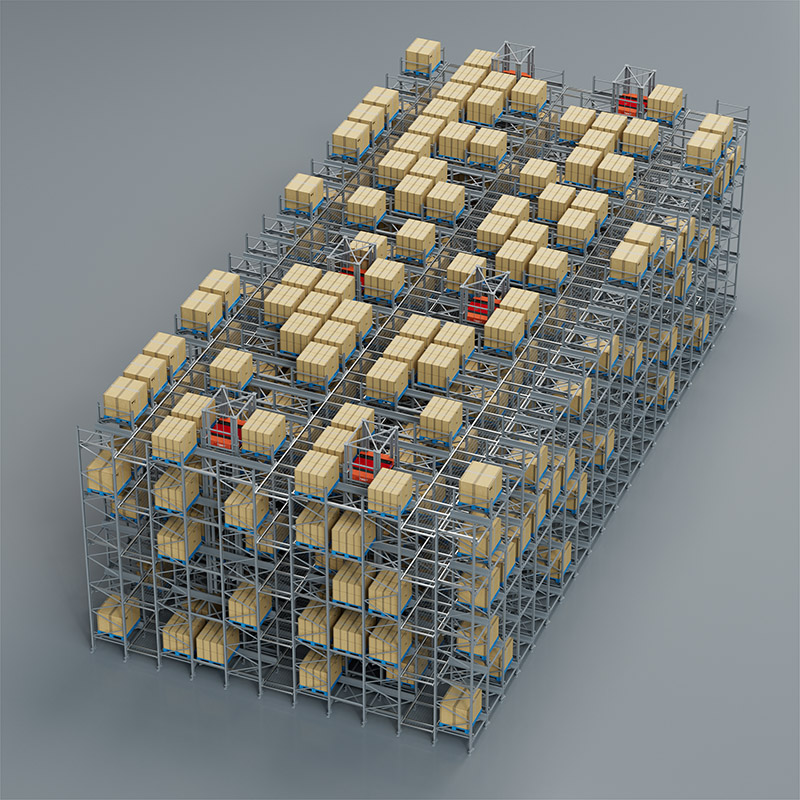

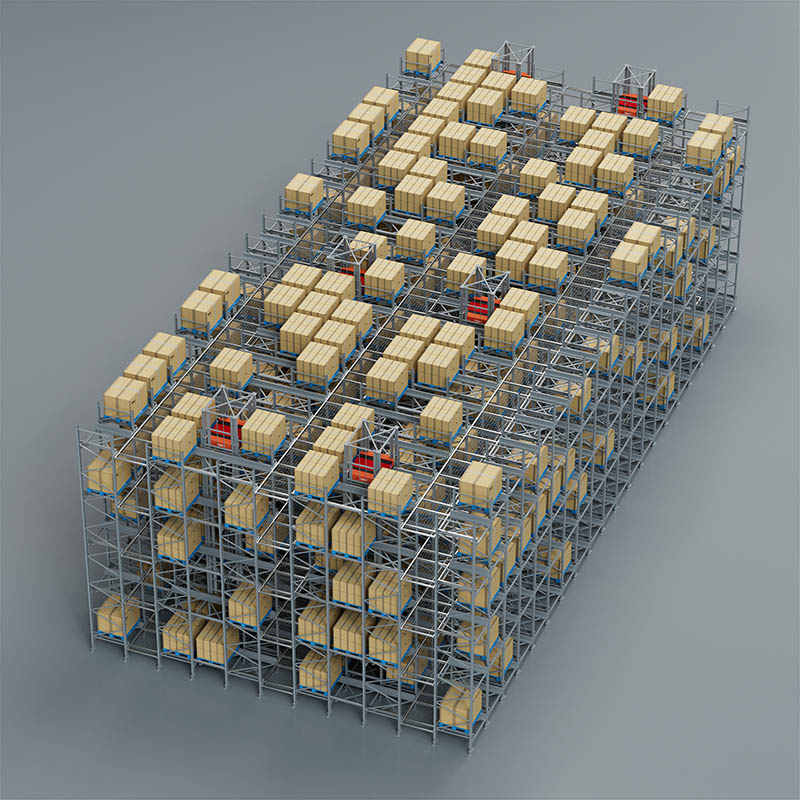

The six-directional shuttle system is an innovative combination of the four-directional shuttle car and the vertical two-directional vehicle. It can achieve six-directional movement (horizontal-vertical, front-back, left-right), completing goods storage, retrieval, and handling tasks on shelf tracks.

This pallet shuttle system allows flexible planning of storage locations based on site layout, deep storage by SKU, and buffer zones tailored to throughput needs. It can adapt to diversified application scenarios such as dense storage and integrated storage-picking, and is suitable for multiple industries including food, manufacturing, cold chain, retail, footwear & apparel, and supermarkets.

Core Features

6-Directional Movement: Combines horizontal (front-back/left-right) and vertical (up-down) mobility to access every storage location across multiple shelf levels—no need for separate lifting equipment (e.g., forklifts) to connect levels.

Flexible Deployment & Layout Adaptability: Customize storage locations based on your warehouse's unique layout (e.g., narrow aisles, tall racks); Design deep storage zones by SKU and dedicated buffer zones to match your throughput demands (e.g., peak-season inventory surges).

Seamless System Integration: Works with most mainstream WMS/ERP systems (e.g., SAP, Oracle, Manhattan Associates) to sync real-time inventory data, reduce manual data entry, and streamline order fulfillment.

High Density & Throughput: Maximizes warehouse space utilization by reducing aisle width and enabling "deep lane" storage. Boosts throughput by 30-50% compared to traditional shuttle systems (via simultaneous multi-location picking/storing).

Versatile SKU Support: Accommodates unlimited SKUs, from small parts to large pallets—suitable for mixed-inventory operations (e.g., retail, manufacturing).

System Composition

Every HEGERLS 6-Way Shuttle System is built with modular, scalable components to fit your warehouse's needs:

| Component | Function |

| Four-Way Shuttle | Handles horizontal movement (front-back/left-right) on shelf tracks; moves pallets between storage positions. |

| Vertical Two-Way Vehicle | Enables vertical lifting to connect different shelf levels (e.g., from Level 1 to Level 5); eliminates level-to-level delays. |

| Racking & Pallet System | Customizable steel racking (adjustable height/depth) and compatible pallets (EU/US standard); optimized for high-weight loads. |

| WCS/WMS Software | WCS (Warehouse Control System) manages shuttle/vehicle coordination; WMS syncs inventory, orders, and reporting. |

| Integrated Support Equipment | Includes safety sensors (anti-collision), charging stations (for 24/7 operation), and maintenance tools. |

Application Scenarios

Warehouse Storage for the Food Industry

Storage Solutions for Manufacturing

Cold Chain Storage Systems

Storage Solutions for Energy Industry

Storage for Chemicals

Building Materials Warehouse

FAQ

1.What makes the 6 way shuttle system different from traditional shuttle systems?

The 6 way shuttle system is an innovative integration of four-way shuttles and vertical two-way vehicles, enabling full six-directional movement. It offers unmatched flexibility and storage optimization. This is the main difference between the 6 way shuttle system and traditional 2 way or 4 way shuttle systems.

2.Is the system compatible with our existing WMS/ERP?

Absolutely. Our shuttle supports integration with most mainstream WMS/ERP systems. Contact us to know more detailed information and a custom solution.

3.Do you offer on-site support and training?

Yes, we provide global installation, training, and after-sales service.

4.Why Choose HEGERLS 6-Way Shuttle?

HEGERLS provides cutting-edge warehouse automation with proven engineering expertise and global project experience. Our 6-way shuttle system ensures high throughput, maximum flexibility, and long-term cost savings, making it the ultimate choice for businesses upgrading to smart logistics solutions.

5.Ready to Upgrade Your Smart Warehouse?

Contact us today for a free consultation and personalized 6D shuttle system solution. Let's build a high-density, efficient warehouse that scales with your growth.