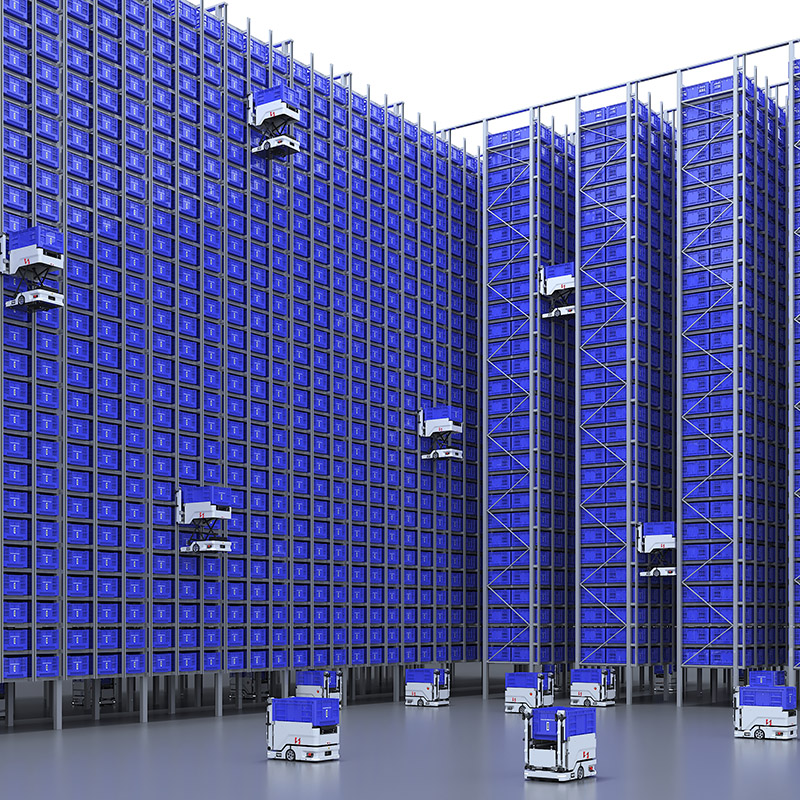

HEGERLS Climb Robot System

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Parameters

Project Item | Bin Height 300mm | Bin Height 400mm |

Dimensions (L×W×H) (mm) | Low: 781×467×720 High: 781×467×1067 | Low: 781×467×815 High: 781×467×1162 |

Lifting Stroke | 340 mm | |

Net Weight | 74.5 kg | |

Maximum Payload | 30 kg | |

Shelf Docking Pick Height Range | 800–11600 mm | 900–11600 mm |

Bin Size (L×W×H) | 650×450×300 mm | 650×450×400 mm |

Conveyor Docking Pick Height | 460 (customizable based on project) | |

Navigation Method | QR Code + Inertial Navigation | |

Communication Method | Wi-Fi 5GHz 802.11n | |

Maximum Chassis Travel Speed | 4.0 m/s | |

Maximum Chassis Acceleration | 1.8 m/s² | |

Maximum Vertical Lifting Speed | 1.0 m/s | |

Maximum Vertical Acceleration | 0.5 m/s² | |

Battery Type | 48V, 15Ah Lithium Iron Phosphate (LiFePO₄) | |

Cycle Life | ≥ 1200 cycles | |

Full Charging Time (20%–100%) | ≤ 0.95 hours | |

Full-Charge Runtime (100%–20%) | ≥ 4.3 hours (at 30kg load) | |

Operating Temperature | 0–45°C | |

Operating Humidity | 10%–90% RH, non-condensing, frost-free | |

Noise Level | ≤ 75 dB(A) | |

Features and Advantages

Simple to Deploy, Built for Speed

HEGERLS Climb is designed with simplicity at its core — easy to learn, quick to implement, and highly scalable. Its single-side guide rail design significantly lowers requirements for ground flatness and shelf installation precision, allowing rapid deployment without complex infrastructure. The robots are plug-and-play — simply power on and start operating.

Fast deployment: No complicated site requirements

Low space demand: Achieve ultra-high storage density with minimal footprint

Extreme throughput: Up to 4,000 bins/hour per 1,000 m²

Scalable and Space-Efficient

With a maximum storage height of 12 meters and no need for aisle switching systems, HEGERLS Climb supports dense vertical racking, providing up to 30,000 storage locations per 1,000 m². Whether expanding robot count or adding system modules, the platform scales seamlessly without disrupting ongoing operations.

Expand capacity by simply adding more robots

Compact body supports narrow aisles and high-density layouts

Adaptive to growing business demands

Smart Robot, Smarter Operations

The HEGERLS Climb robot is purpose-built for split-case picking scenarios. With a compact frame and dual-side picking capability, it climbs racks with just two contact points, optimizing energy efficiency while minimizing wear on infrastructure.

Key Features:

Climbs racks from one side with only 2 contact points

Travels under racks freely to find the shortest route

Dual-side bin picking from both rack faces

Ready to use out of the box — no coding or complex setup

Exceptionally suited for tight spaces and narrow aisles

Industries & Use Cases

E-commerce & Retail: Handling high order volumes, seasonal spikes, and diverse SKUs (e.g., apparel, electronics).

Third-Party Logistics (3PLs): Managing multiple clients with varying needs; scaling for peak periods (e.g., Black Friday).

Pharmaceuticals & Healthcare: Ensuring accuracy for regulated products (e.g., medications, medical devices).

Manufacturing: Kitting and assembly line supply (delivering parts to workers on-demand).

Food & Beverage: Temperature-controlled warehouses (robots operate in cold storage, reducing worker exposure to harsh conditions).

FAQ

What industries is the HEGERLS Climb Robot system suitable for?

It's ideal for e-commerce, pharmaceuticals, retail, electronics, and spare parts warehousing — any operation requiring fast, efficient split-case picking.

How does it compare with traditional shuttle or miniload systems?

HEGERLS Climb offers easier deployment, lower infrastructure requirements, and greater flexibility. Its robots can climb and navigate freely, eliminating complex track systems.

Is it easy to expand the system later?

Yes, simply add more robots or extend the racking and picking stations. No downtime or major retrofitting needed.