Automated conveying equipment

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

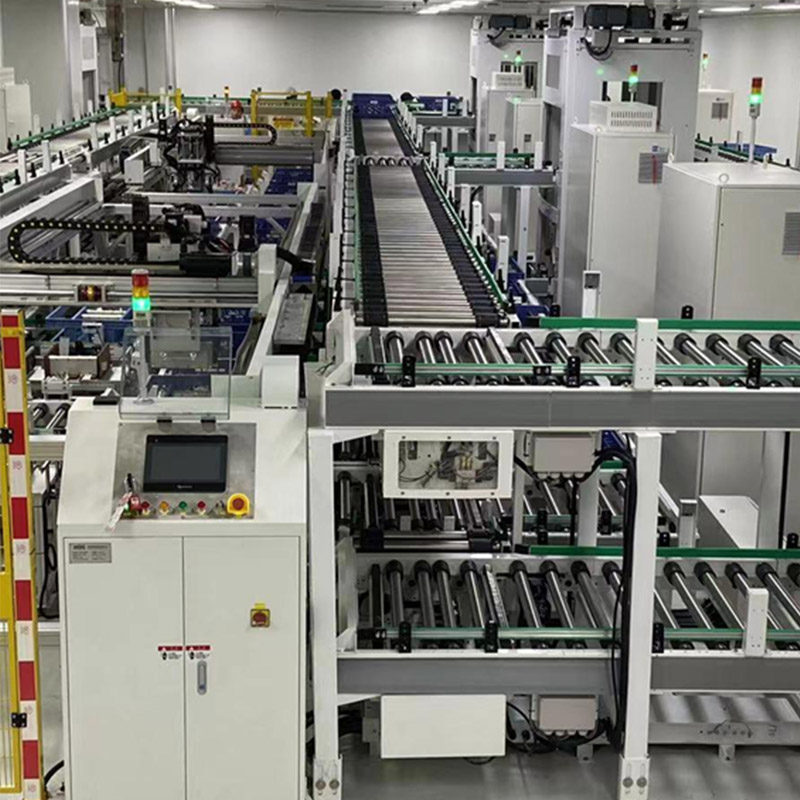

As the core equipment for material handling, automated conveying systems are widely used to ensure the efficient movement of goods in warehouses and production workshops. They consist of multiple types of conveying equipment working in coordination to achieve smooth and continuous logistics operations.

Chain Conveyors – Designed for the long-distance transportation of heavy goods using a robust chain drive system.

Roller Conveyors – Ideal for flexible transport of boxed or palletized goods through the rolling action of durable rollers.

Transfer Machines – Enable the precise transfer of goods between different conveying routes, ensuring seamless workflow integration.

According to the type of items being transported, conveying systems are generally divided into two categories:

Box-type Conveying Equipment – Specially designed for small, packaged goods such as cartons and totes.

Pallet-type Conveying Equipment – Engineered for large and heavy palletized goods.

Together, these systems guarantee the smooth, reliable, and highly efficient flow of goods across all stages of warehousing and logistics.

Types of HEGERLS Automated Conveying Systems

Comprehensive range of automated conveying solutions for diverse material handling needs

Chain Conveyors

Heavy-duty solution for transporting pallets, drums, and containers in demanding industrial environments.

Speed: 12, 16,18 m/min

Length: 951-6051 mm

Load capacity: Up to 1200 kg

Suitable for harsh environments

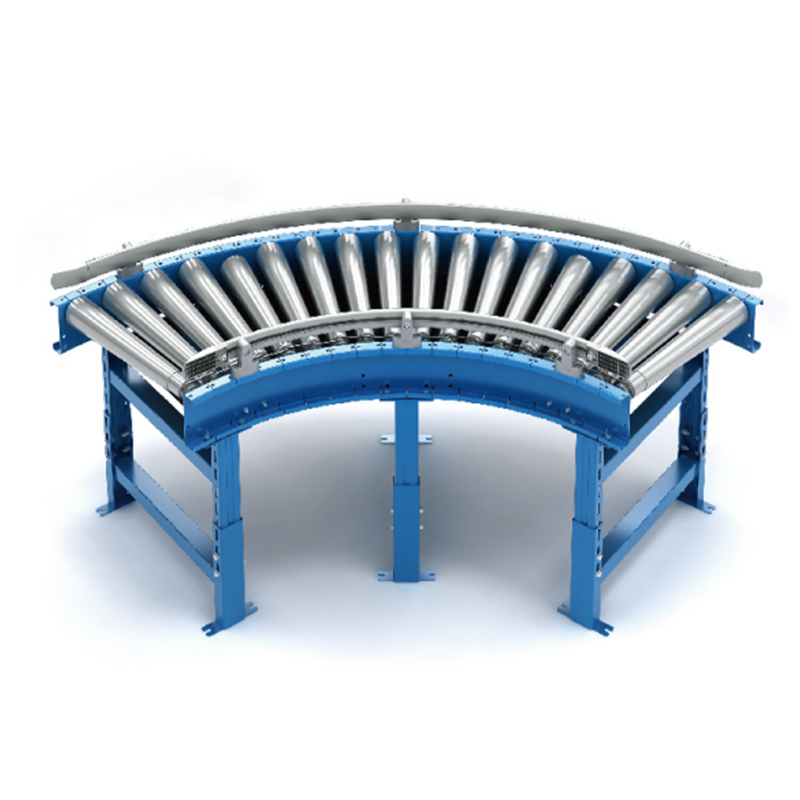

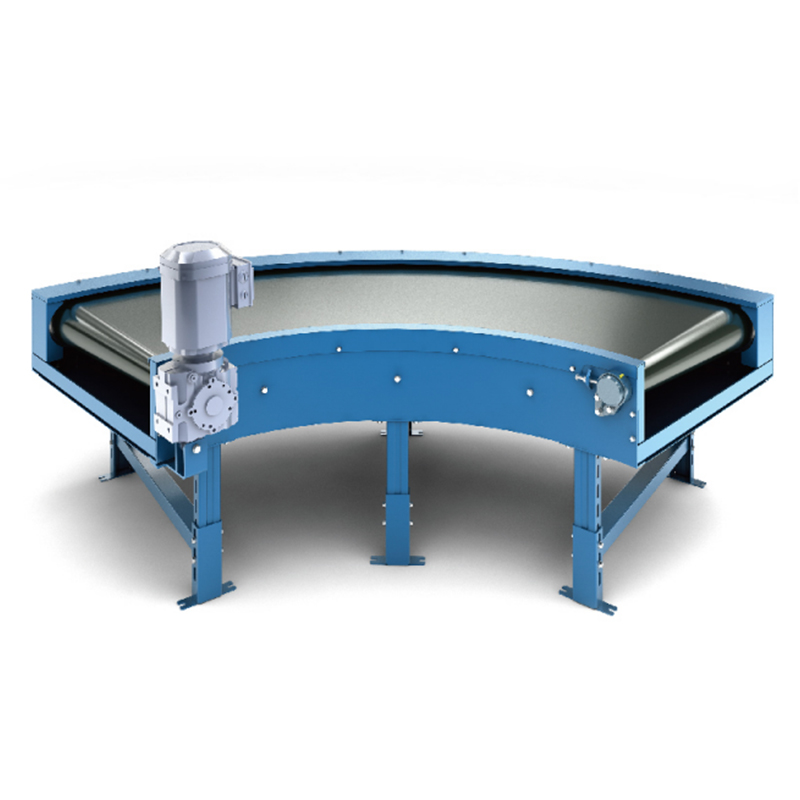

Roller Conveyors

Ideal for pallet handling and heavy loads. Available in gravity, belt-driven, and chain-driven configurations.

Speed: 12-80 m/min

Load capacity: Up to 1200 kg

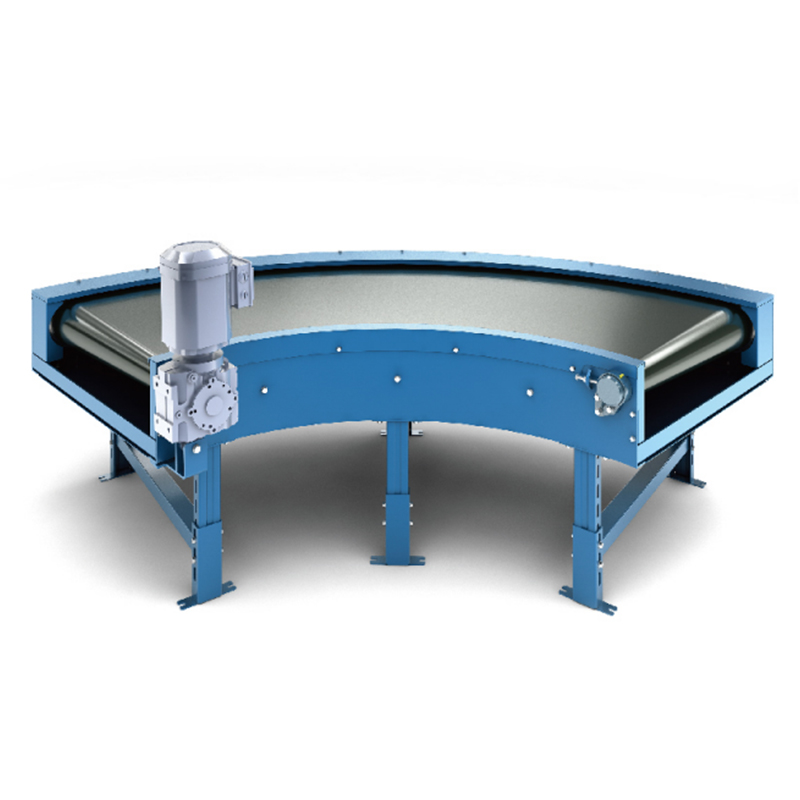

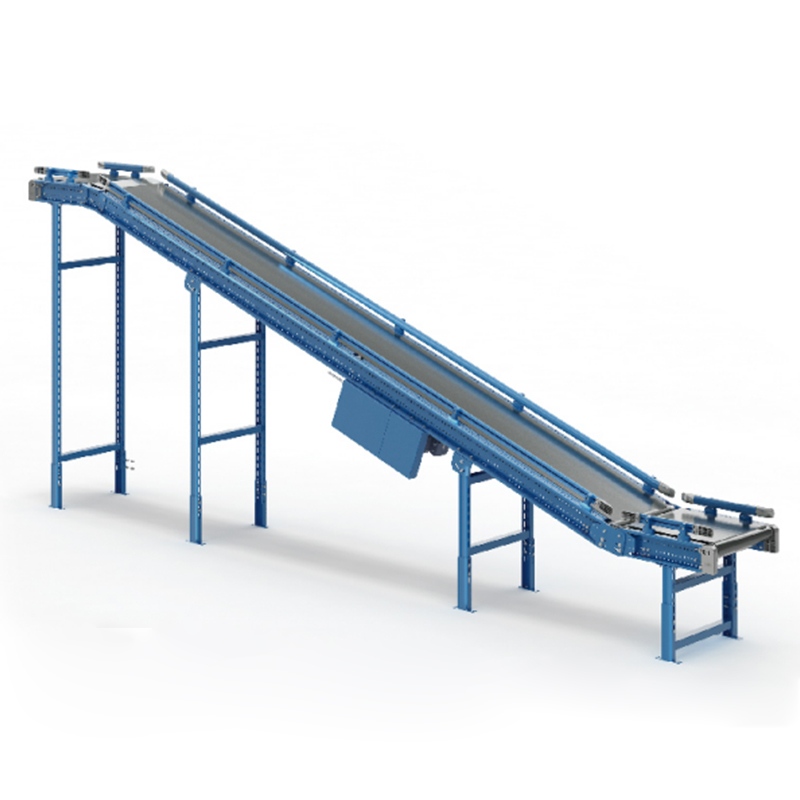

Belt Conveyors

Versatile solution for transporting boxes, packages, and irregularly shaped items. Available in various widths and configurations.

Speed: 15-125 m/min

Load capacity: Up to 50 kg/m

Food-grade options available

Telescopic Conveyors

Perfect for loading and unloading trucks.

Customization solutions.

Modular Conveyors

Flexible layouts that adapt to warehouse changes.

Customization solutions.

Customization Options

We offer tailored solutions to meet your specific requirements:

Specialized coatings for food, pharmaceutical, and hazardous environments

Integration with WMS, ERP, and other warehouse management systems

Custom lengths, curves, and inclines for space-constrained facilities

Advantages of Automated Conveying Equipment

High Efficiency: Enables continuous and rapid movement of goods, significantly improving handling speed and overall productivity. Ideal for large-scale logistics and warehousing operations.

Precision & Accuracy: Ensures accurate positioning and transportation of goods, reducing errors and protecting product integrity during handling.

Flexible & Customizable: Can be tailored to different requirements, including product type, conveying routes, and working environments, making it suitable for diverse applications.

Smart Automatic Control: Equipped with advanced automation systems for intelligent operation, fault detection, and alarm functions, minimizing manual intervention and improving safety.

High Load Capacity: Built to handle heavy-duty loads, making it suitable for transporting large and palletized goods.

Optimized Space Utilization: Designed to match warehouse layouts, efficiently using both vertical and horizontal space to maximize storage capacity.

Low Maintenance Cost: Manufactured with high-quality materials and advanced processes, ensuring durability, reliability, and reduced maintenance expenses.

Industry Applications

Our automated conveying systems serve a wide range of industries:

E-Commerce

Manufacturing

Logistics

Pharmaceuticals

Food & Beverage

Automotive

Why Choose Our Automated Conveying Equipment?

30 years of expertise in automated warehouse solutions

Integration with HEGERLS intelligent storage systems

Proven reliability with installations in Europe, Asia, and North America

Energy-efficient designs that reduce operating costs

HEGERLS is a leading manufacturer of automated conveying equipment and material handling solutions for global industries since 1996.Contact us today to get the custom-engineered solutions for seamless transportation of goods in warehouses, distribution centers, and manufacturing facilities.