YUNTU-WCS Warehouse Control System

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

YunTu Warehouse Control System (YUNTU-WCS) is a middleware control system specifically designed for intelligent warehousing. Operating between the WMS and logistics equipment, enabling unified scheduling and collaborative management of multiple types of intelligent equipment. The system efficiently integrates and schedules mainstream intelligent equipment such as four-way shuttle, AGVs, Stacker cranes, Elevators, and Conveyor systems.

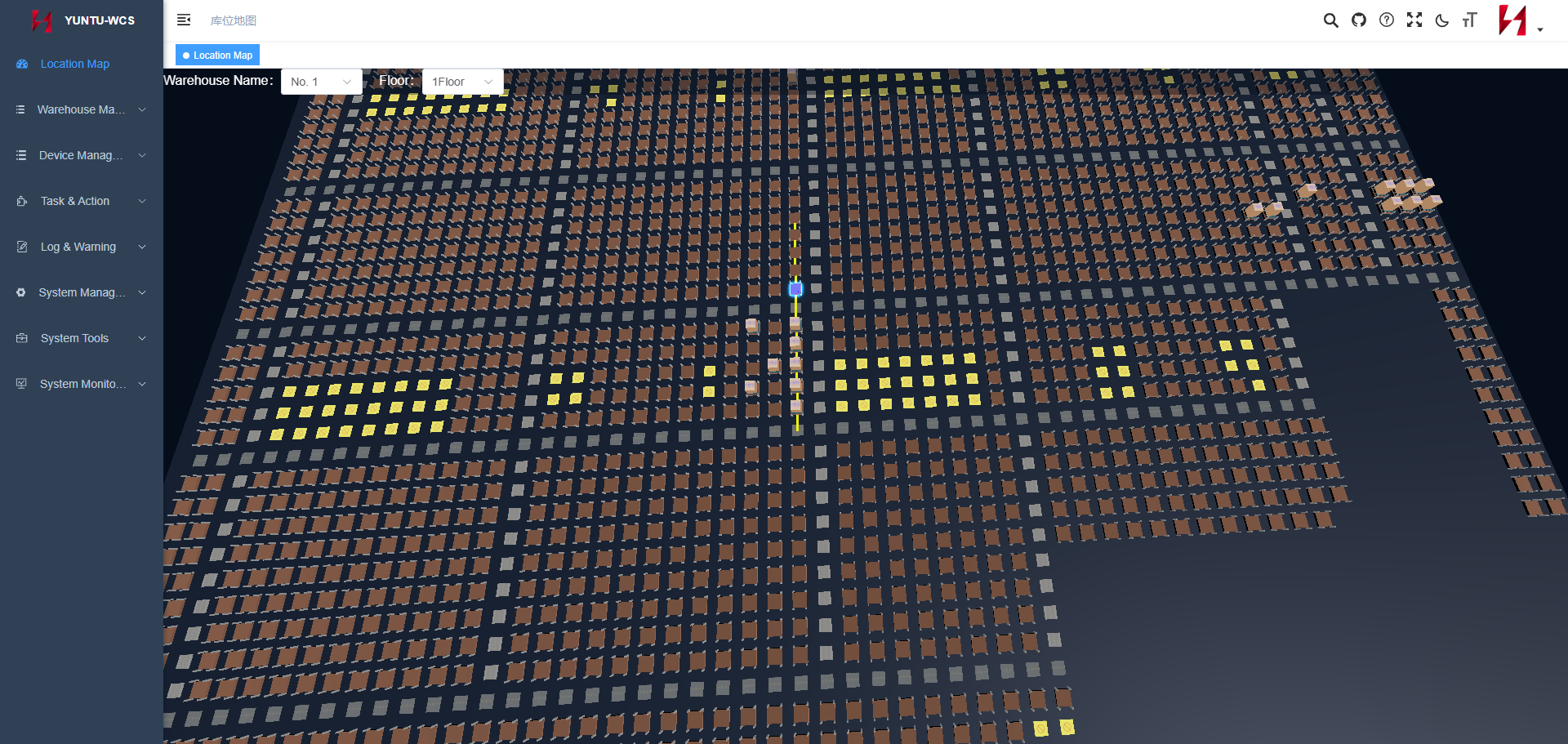

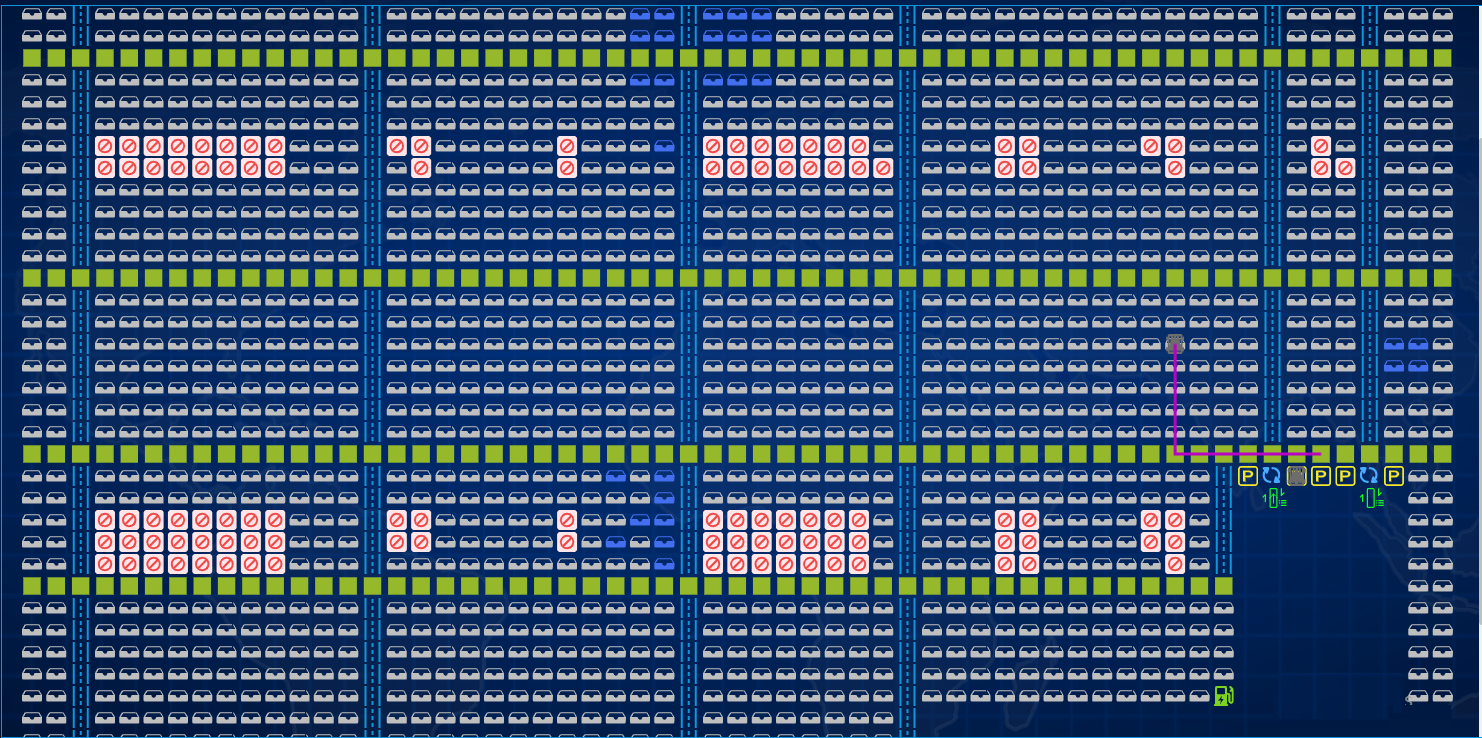

YUNTU-WCS features a real-time 3D equipment operation map, clearly and intuitively displaying the dynamic positions and operational status of various equipment, maintaining near-perfect synchronization with the physical environment. Equipped with independent intelligent scheduling algorithms and path planning algorithms, the system can simultaneously coordinate multiple equipment for collaborative operations, significantly enhancing overall operational efficiency. Its path planning capabilities are particularly suitable for equipment requiring precise navigation, such as four-way shuttles and AGVs. By calculating optimal paths in real-time, enabling rapid response and task decoupling, even in scenarios with complex warehouse layouts and numerous equipment, ensuring continuous, efficient, and stable operation.

Main functions

2D & 3D Map Display

Warehouse Management

Device Management

Task and Action Management

Log and Warning Management

System Management

System Tools

System Monitoring

Key Features & Advantages

1. Home Page Map – 2D & 3D Real-Time Visualization

Supports 2D and 3D map display for intuitive operation.

Real-time tracking of four-way shuttle movement and route, with position deviation less than 1 second.

Simulates shuttle route planning and operation for testing and optimization.

Monitors the real-time status of shuttles, lifts, conveyors, goods, and storage positions, with data synchronization accuracy within 1 second.

2. Task Review – 7-Day Playback & Analysis

Stores all task execution records for the last 7 days.

Allows task playback directly on the map, visually showing route execution.

Quickly identify the cause of vehicle abnormalities through historical playback.

Supports review of automated warehouse tasks such as auto-arrangement and lights-out operations.

3. Intelligent Path Planning & Vehicle Scheduling

Fusion algorithms calculate optimal paths in real time.

The system continuously communicates with all vehicles, tracking their positions to minimize travel time and avoid conflicts.

Independent scheduling algorithms allocate the most suitable four-way shuttle for each task.

Prioritizes assignments to maximize overall operational efficiency.

4. Automatic Recovery of Abnormal Tasks

Over 90% of abnormal tasks can be automatically recovered by the system.

Real-time analysis determines the best recovery solution based on the issue type.

Automatic rescue actions are triggered instantly when problems occur.

Real-time alerts with on-map abnormal location markers, detailed cause analysis, and suggested solutions.

If a vehicle cannot recover automatically within a set time, the system alarms and escalates for manual intervention.

Why Choose HEGERLS YUNTU-WCS Warehouse Control System?

Precision & Speed: Real-time data synchronization within 1 second.

High Reliability: 90%+ automated recovery rate for abnormal tasks.

Smart Decision-Making: AI-powered path planning and scheduling.

Full Visibility: 2D/3D interactive map for complete warehouse monitoring.

Operational Efficiency: Maximizes throughput while reducing idle time.