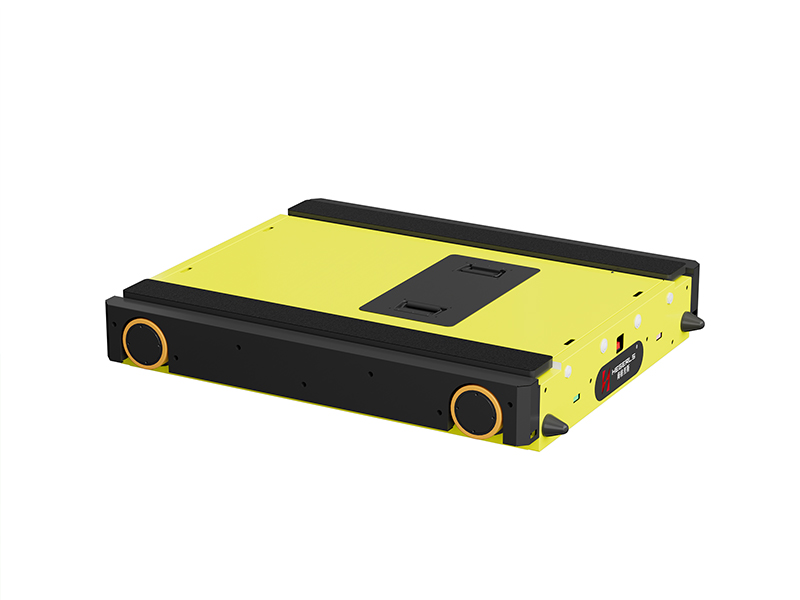

Two-Way Shuttle System for High-Density Warehousing

- Hegerls

- Xinhe Industrial Park, Hebei, China

Product Introduction

HEGERLS Two-Way Shuttle System is a high-performance solution designed for intelligent, space-saving warehouse storage. By running on preset rails, it automates pallet movement within racking lanes, increasing operational efficiency and reducing manual intervention. Ideal for cold chain logistics, food & beverage, third-party logistics (3PL), e-commerce fulfillment centers, etc., with a scene adaptation rate of up to 90%.

Product Parameter

HEGERLS Two-Way Shuttle Basic Parameters: HGLS-L-Y-01 | |

Specifications | Parameters |

Load Capacity | 1500 kg |

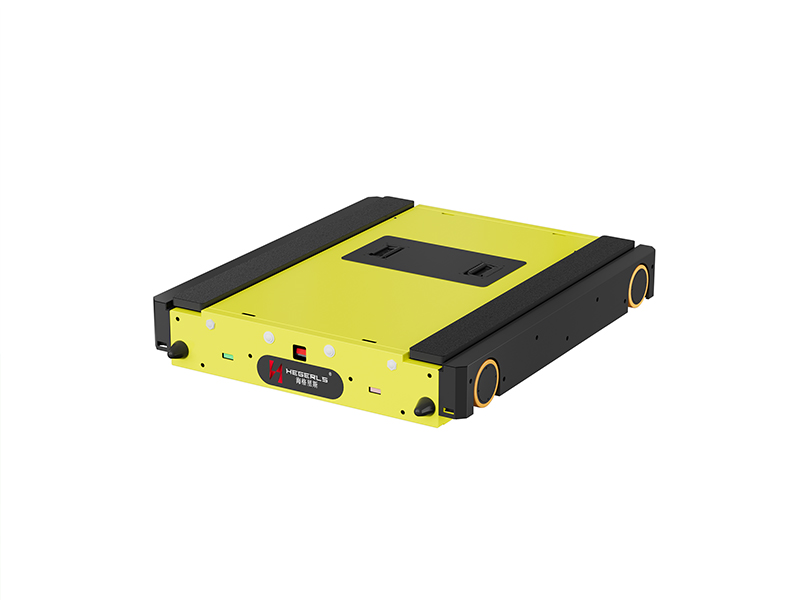

Dimensions | L×W×H (1120mm×960mm×170mm) |

Weight | 250 kg |

Applicable Pallet Size | Width: 1200 mm, Depth: 1000 mm |

Compatible Rail Size | 150 / 163 / 170 |

Communication Method | Wi-Fi Wireless Communication |

No-load Travel Speed | 1.5 m/s |

No-load Acceleration | 0.8 m/s² |

Full-load Travel Speed | 1.2 m/s |

Full-load Acceleration | 0.4 m/s² |

Lifting Height | 40 mm |

Power Supply | Lithium Iron Phosphate Battery 48V–30Ah |

Operating Time | ≥8 hours |

Charging Time | 3.5 hours |

Operating Environment | Temperature: -40°C to 60°C, Humidity: 5%–95% (non-condensing) |

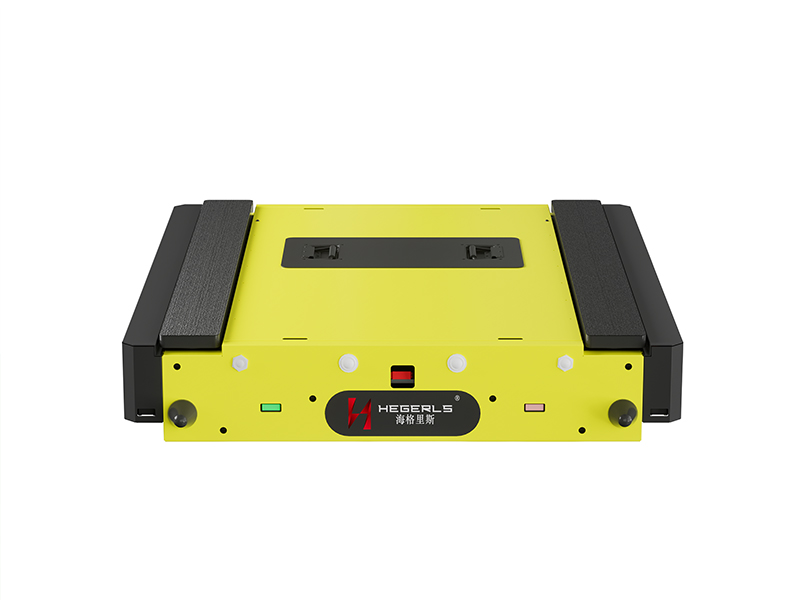

Anti-collision Device | Polyurethane buffers and sensors on both ends |

Travel Positioning Accuracy | ±2 mm |

Standard Functions

Inbound (Loading) – Supports precise pallet loading into the designated storage position.

Continuous Loading – Enables uninterrupted loading operations for higher efficiency.

Outbound (Unloading) – Handles pallet retrieval quickly and accurately.

Continuous Unloading – Streamlined unloading process for batch operations.

FIFO / FILO – Flexible inventory management supporting both First-In-First-Out and First-In-Last-Out strategies.

Pallet Counting – Automatic pallet counting for accurate inventory control.

Manual Commands – Allows operators to run the system manually when required.

Anti-Collision – Built-in safety sensors to prevent shuttle collisions.

Emergency Stop – Immediate halt of operations to ensure personnel and equipment safety.

Emergency Back – Shuttle automatically returns to the designated position during emergencies.

Advantages of HEGERLS Two-way Shuttles

High-Speed & Continuous Operation: The two-way shuttle runs at 1–2 m/s, completing each storage or retrieval task in just 10–20 seconds, handling 30–50 pallets per hour—3–5 times faster than manual forklifts.

Multi-Shuttle Coordination & Optimized Scheduling: Multiple shuttles can operate simultaneously across different aisles with intelligent task allocation, reducing idle time and increasing overall warehouse efficiency by over 40%.

Narrow Aisle Operation: With a compact body (typically 0.8–1.2 meters wide) and rail guidance, the two-way shuttle can operate in aisles as narrow as 1.2–1.5 meters—much tighter than the 3–4 meters required by traditional forklifts. This allows for 30–50% higher racking density and over 90% space utilization in high-bay warehouses.

Vertical Space Utilization: Working with high racks up to 10–20 meters, the shuttle supports vertical storage by integrating with forklifts or lifts, enabling precise pallet placement at any level.

No Aisle Waste: Unlike forklifts that require turning space, the shuttle runs in a straight line within the aisle. Shelving only needs to accommodate the shuttle's width, minimizing dead space between racks.

Multi-Type Cargo Compatibility: Supports various pallet types and loads (500–2000kg), suitable for standard or custom sizes—ideal for food, pharma, and manufacturing storage.

Versatile Application Scenarios: Works in -40℃ to +60℃ environments for cold chain use; supports FIFO/LIFO storage for goods with shelf-life requirements; enables tiered storage by turnover rate to boost efficiency.

Modular & Scalable Deployment: Start with 1–2 aisles and expand by adding shuttles or aisles as needed—offering flexible, cost-controlled growth.

Customizable Design: Shuttle parameters like speed, lift height, and load capacity can be tailored to meet specific operational needs.

Lower Initial Investment: Compared to four-way shuttles or stacker cranes, two-way shuttles have a simpler structure and cost 20–30% less—ideal for budget-conscious automation upgrades.

Low Maintenance & Long Lifespan: With fewer wear parts and simple mechanics, maintenance is needed only every 1–2 years, reducing costs by up to 50%. Lithium batteries last 8–10 hours and support fast charging.

Significant Labor Savings: Only 2–3 operators are needed for a 10,000㎡ warehouse, cutting labor costs by 70–80%—especially valuable in labor-scarce regions.

Safe Structural Design: Equipped with sensors for stopping, deceleration, and obstacle detection, the shuttle can brake within 0.5m to prevent collisions. Speed and load limits ensure safe operation, with alarms for added protection. Its upgraded gear-and-rack lifting system boosts transmission efficiency by 30%, reliability by 80%, and accuracy by 60%—ensuring zero failures over its lifespan.

Strong Environmental Adaptability: Operates reliably in harsh conditions like low temperatures, dust, and noise, with enclosed design reducing risks and minimizing human error in extreme environments.

Energy-Efficient Electric Drive: Powered by lithium batteries or supercapacitors, the two-way shuttle consumes only 0.5–1 kWh per hour—cutting carbon emissions by over 90% compared to diesel forklifts and meeting green warehouse standards.

Low-Noise Operation: Operating below 65 decibels, it's ideal for warehouses in industrial parks or near residential areas, eliminating noise pollution and improving workplace comfort.

Applicable industries

Food

Tobacco

Beverage

Chemical industry

Home appliances

Case Study

Shuttle Racking System for Military Grain Storage

High-Density Shuttle Racking for Wine Storage

HEGERLS Semi-Automated Shuttle System for Xingtai Dalis Toys

FAQ

Is the shuttle system customizable for different pallet sizes?

Yes, we offer size customization based on your warehouse needs. Some models feature fully customizable designs, with parameters such as walking speed, lifting height, and full load capacity all customizable according to requirements.

How long does the battery last?

Each battery supports up to 8–10 hours of continuous use and supports fast charging, and reduces downtime.

Can two-way shuttle system operate in cold storage?

Yes, our shuttle system is engineered to operate in environments down to -40°C.

Does HEGERLS two-way shuttle pallet system work with existing racks?

It can be integrated with standard racking, but optimal performance is with HEGERLS shuttle-compatible racks. Contact us for the custom solutions.

How is maintenance handled?

We provide full technical documentation, remote support, and global after-sales service.

Ready to Upgrade Your Warehouse Efficiency?

Contact us today for a free consultation and customized two way shuttle system solution.