Anticorrosive Shelving

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

Developing shelving with higher corrosion resistance has always been the goal of warehousing professionals. To this end, based on traditional processes, studies have been carried out on the selection of special steel with added alloys such as Al, Mg, Ni and Cr, surface treatment processes and the selection of supporting accessories. Within a certain range, the increase in the content of Al, Mg, Ni, and Cr makes the steel plate several to more than ten times more corrosion-resistant than ordinary plates.

The application of special steel with added alloys such as Al, Mg, Ni, and Cr in HEGERLS' anti-corrosion shelving dates back to the early 2000s. The primary objective was to further enhance the corrosion resistance of steel plates. Surface treatment plays a crucial role throughout the production process of anti-corrosion shelving. Strict quality control is implemented across multiple stages: pre-treatment before machining, equipment calibration during processing, post-treatment after machining, surface passivation, and coating application. These measures collectively ensure the shelving's anti-corrosion performance. Additionally, the use of compatible accessories during the installation process further safeguards the product's corrosion resistance.

HEGERLS anticorrosive shelving products can be applied in industries such as hazardous waste treatment, chemical engineering, tanning, and planting.

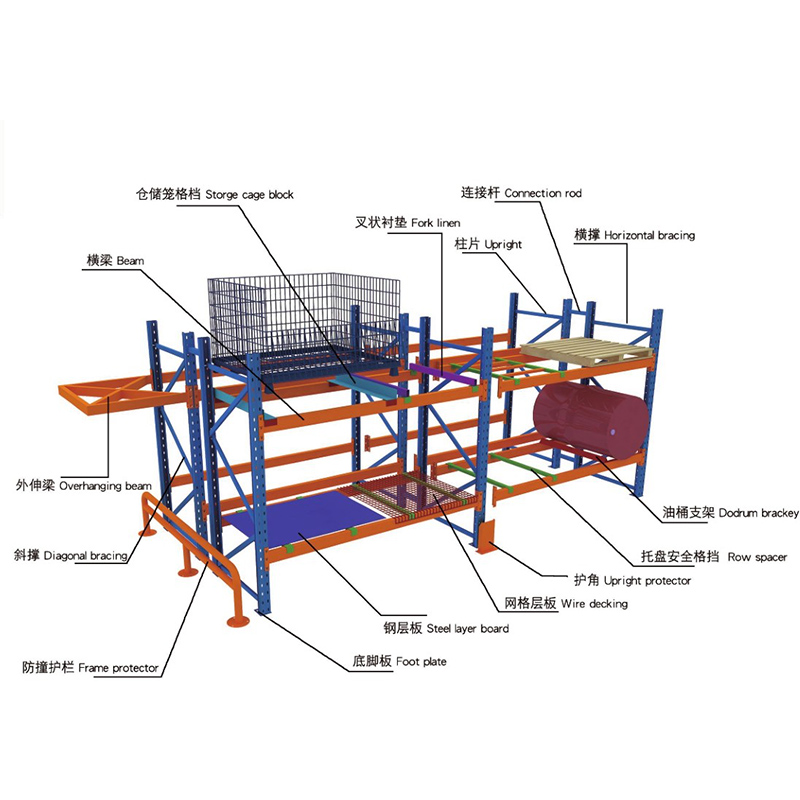

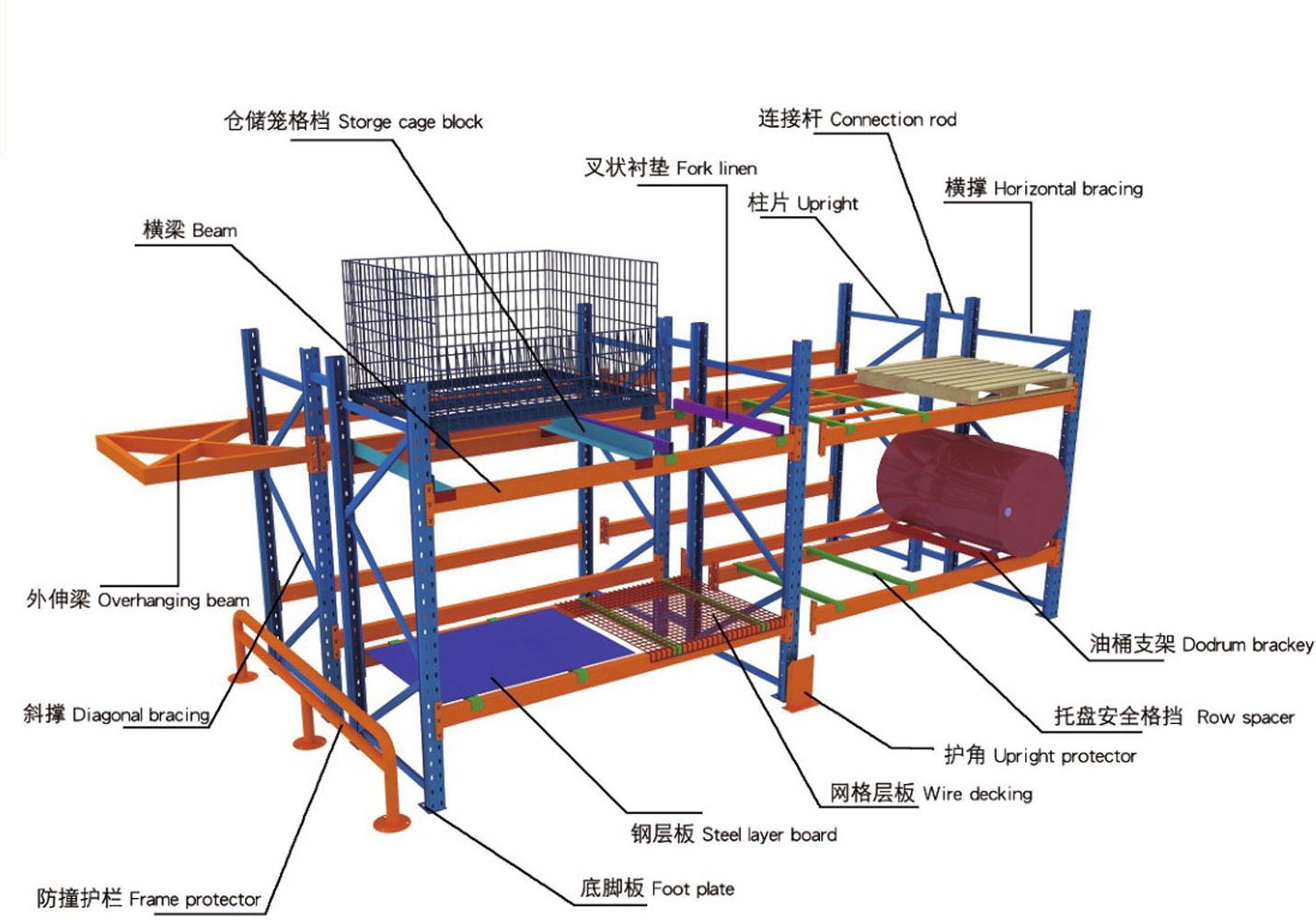

Styles of HEGERLS Anticorrosive Shelving Products:

Beam-type

Shuttle-type

Bracket-type

Drive-in type, etc.

Varieties Include:

Anticorrosive shelving for acidic environments

Anticorrosive shelving for alkaline environments

Anticorrosive shelving for comprehensive environments

Surface Treatment:

Degreasing, passivation, electrostatic spraying

Coating Thickness:

100-200 microns

Extensive Application Areas

The application of anticorrosive shelving in the hazardous waste treatment industry has greatly reduced the investment cost of fixed assets for hazardous waste enterprises, and also reduced the management and time costs caused by replacing shelves.

| Industry | Specific Application Scenarios | Shelving Benefits |

| Hazardous Waste Treatment | Temporary storage and classification of hazardous waste | Reduces shelving replacement costs and meets environmental compliance requirements |

| Chemical/Pharmaceutical | Storage of corrosive raw materials (e.g., North China Pharmaceutical) and pharmaceutical cool storage | Meets GMP certification requirements and prevents raw material leakage and corrosion |

| Food/Frozen | Dairy refrigeration and frozen food storage | Resists low-temperature condensate corrosion and ensures food hygiene |

| Leather/Textile | Storage of leather raw materials (certified by Xinji Leather Association) and textiles | Resists tanning liquid corrosion and protects against moisture and mildew |

| Automotive/Industrial Manufacturing | Storage of automotive parts (e.g., Bosch Group) and equipment accessories | Meets Bosch's global supply chain system certification and resists workshop oil corrosion |

Impressive Customer Cases

We have collaborated with hazardous waste treatment enterprises to conduct demonstration designs for replacing Q235 and Q345 with anticorrosive materials followed by hot-dip galvanizing, as well as demonstration designs for anticorrosive treatment during processing and coating selection. These efforts meet the high corrosion resistance and standardized management requirements of the hazardous waste treatment industry. The solutions have been applied to renowned users in the domestic hazardous waste treatment sector.

Anticorrosive shelving is widely used in leading chemical enterprises such as North China Pharmaceutical and Lanrun Chemical. It has passed the system certification audit of Bosch Group, the world's top automotive parts enterprise. It has also obtained the certification of Xinji Leather Industry Association and completed preliminary trial certification with domestic well-known tanneries such as Senselong, Hongsihai, and Ruitai.

Anticorrosive Pallet Racking for Environmental Hazardous Waste Treatment Industry

HEGERLS Comprehensive Service Support

Pre-sale Customization: You'll be assigned an exclusive customer service team consisting of sales, R & D, and design professionals. They will conduct on-site surveys and provide customized solutions, ensuring that the shelving system is tailored to your specific needs.

In-sale Implementation: Our professional installation and debugging team will oversee the entire process, from production to delivery and installation, with strict quality control. We guarantee 100% acceptance before handover, so you can rest assured that your investment is in good hands.

After-sale Maintenance: We offer at least one on-site visit per year to inspect the condition of the shelves. In case of any issues, our 24-hour response service ensures that we will be on-site within 24 hours and provide a solution within 48 hours.