Automotive Industry Racking Solutions-HEGERLS

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Challenges in Automotive Storage

High SKU Diversity – From nuts and bolts to engines, storage solutions must accommodate widely varying sizes and weights.

Heavy & Bulky Components – Tires, transmissions, and bumpers require racks with strong load-bearing capacity.

Huge Turnover Differences – Brake pads may turn over 30 times per month, while old-model headlights might remain untouched for six months.

Specialized Storage Requirements – Precision electronic components require ESD (anti-static) protection, while oil-based and flammable products must be stored in spark-proof environments.

Just-in-Time Manufacturing – Production schedules demand precise inventory control and quick access.

Aftermarket Logistics – Parts warehouses must handle frequent order picking and fast dispatch.

Automation Trends – Automotive supply chains are adopting shuttles, stacker cranes, and AS/RS to boost efficiency.

HEGERLS Racking Solutions for the Automotive Industry

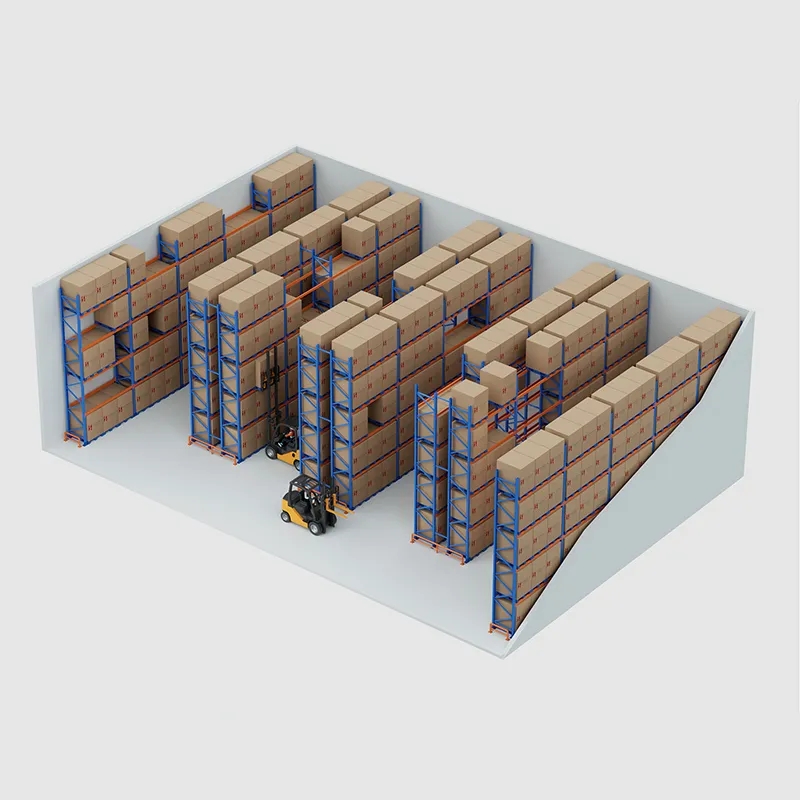

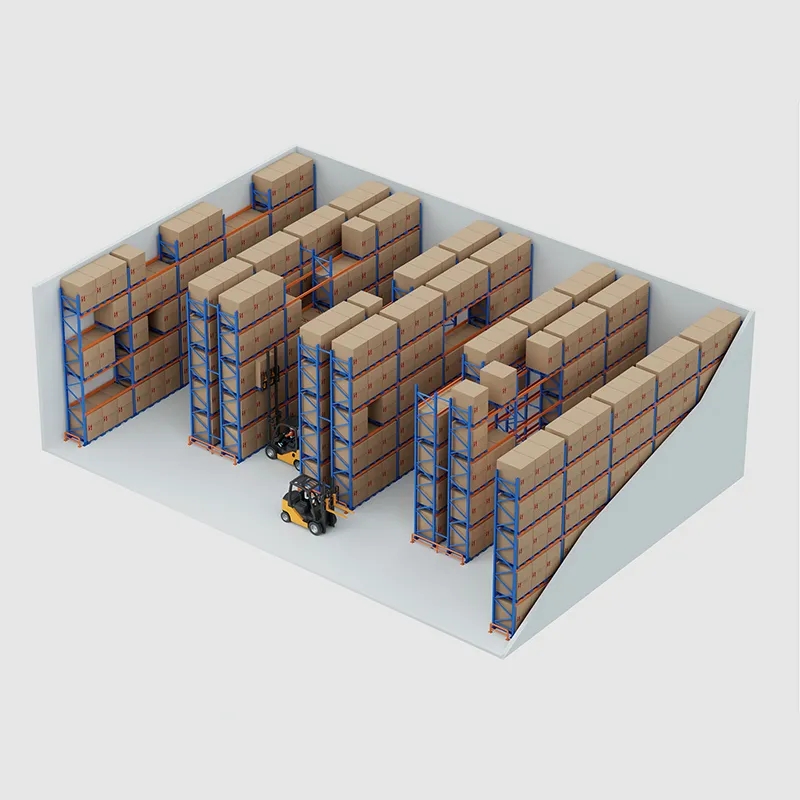

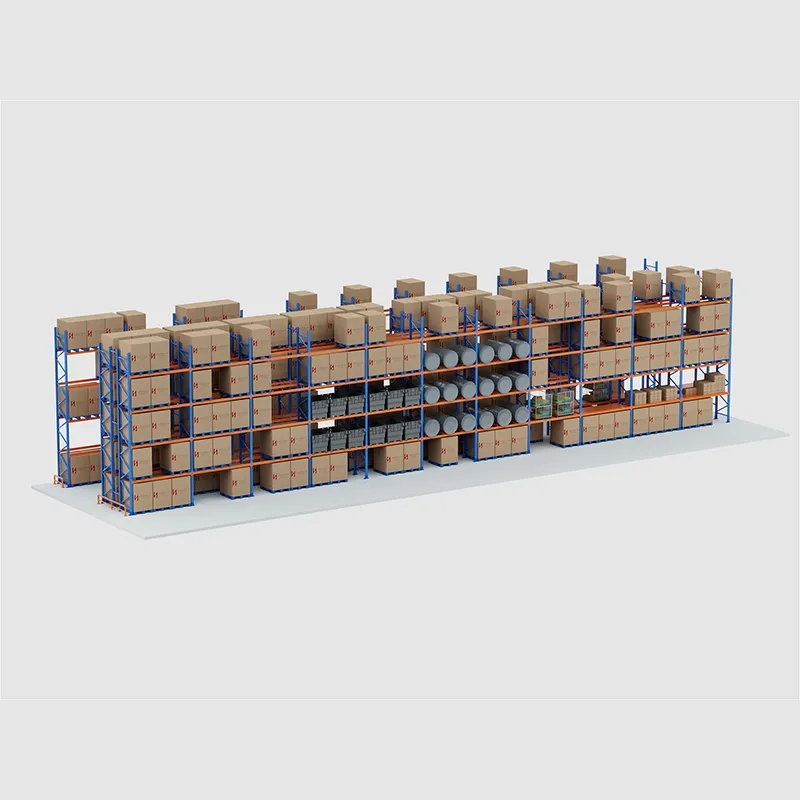

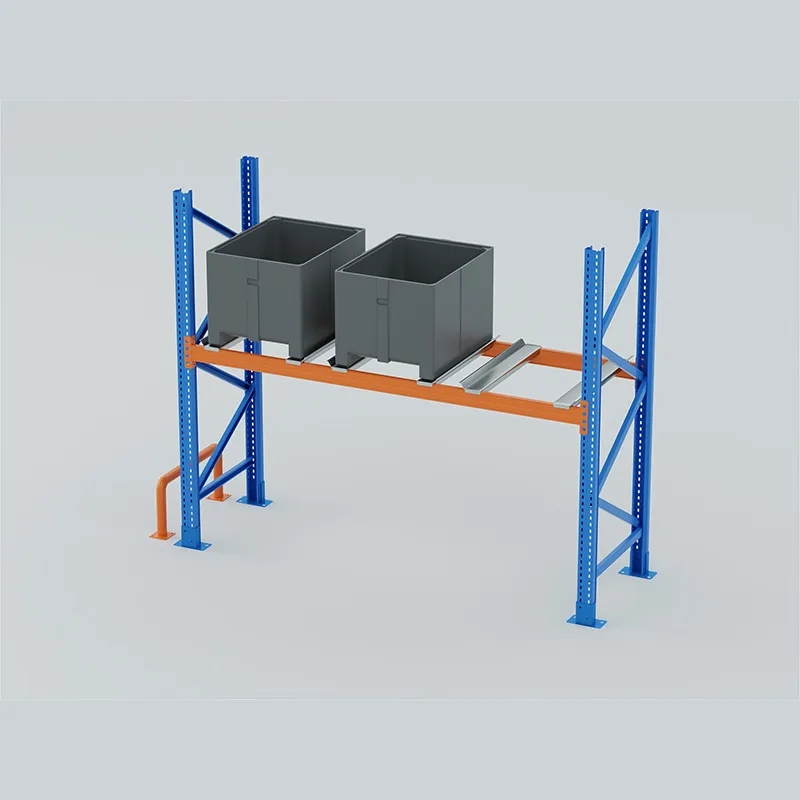

1.Pallet Racking Systems

Ideal for engines, gearboxes, raw materials, and large parts. Configurations include:

Selective Pallet Racking – Flexible access to every pallet.

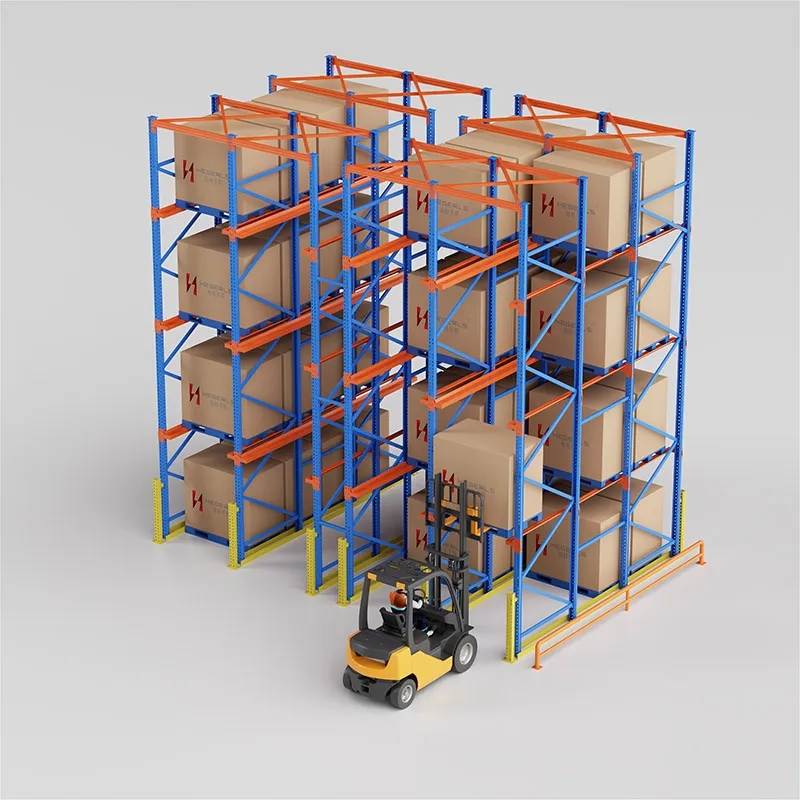

Drive-In / Drive-Through Racking – High-density storage for uniform items.

Double-Deep Pallet Racking – Balance between density and accessibility.

2.Tire Racking/product-long-span-racking.html

Specialized designs for efficient, safe, and space-saving storage of tires in warehouses, distribution centers, and dealerships.

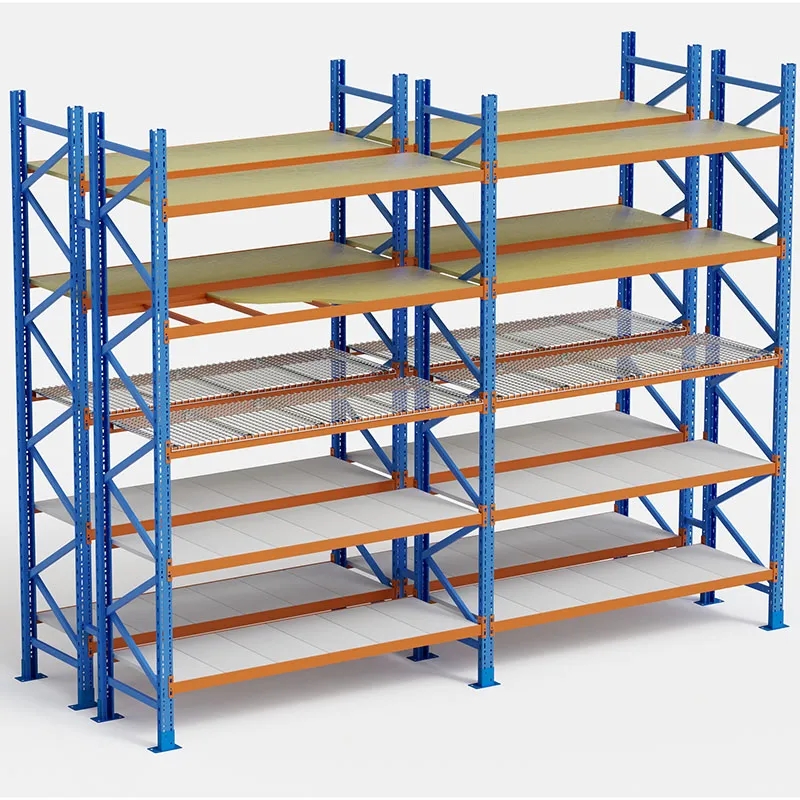

3. Long-Span & Shelving Systems

For small and medium-sized items such as bolts, filters, brake pads, and accessories.

Adjustable shelves for fast reconfiguration.

Compatible with bins and boxes for order picking.

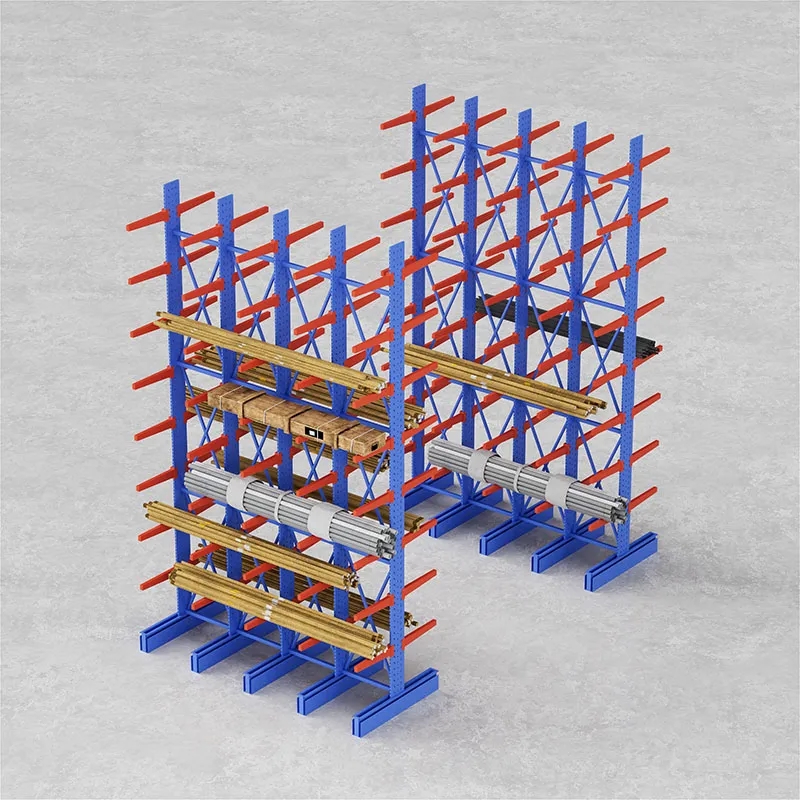

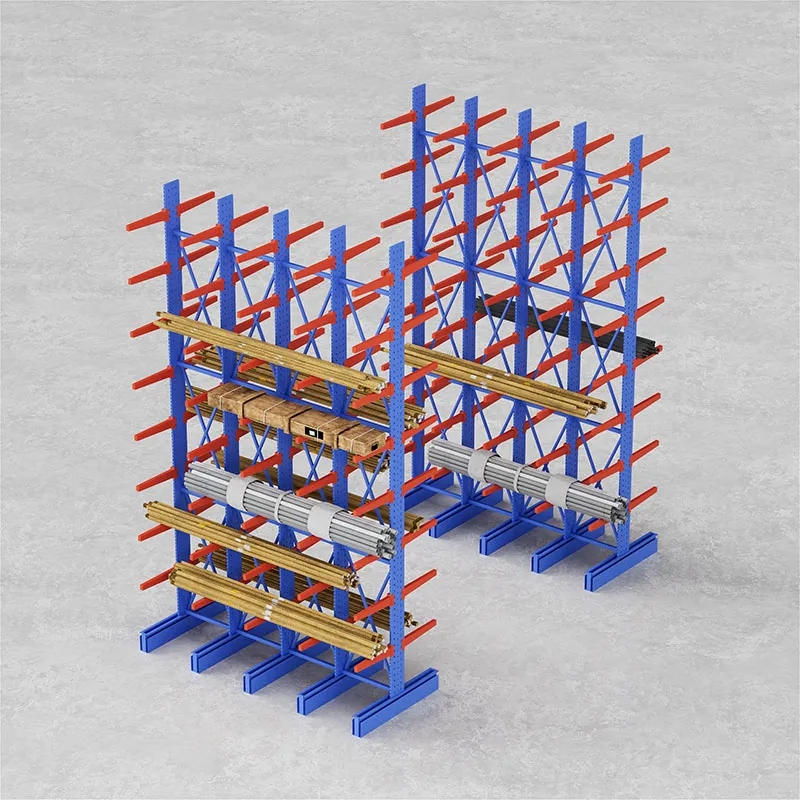

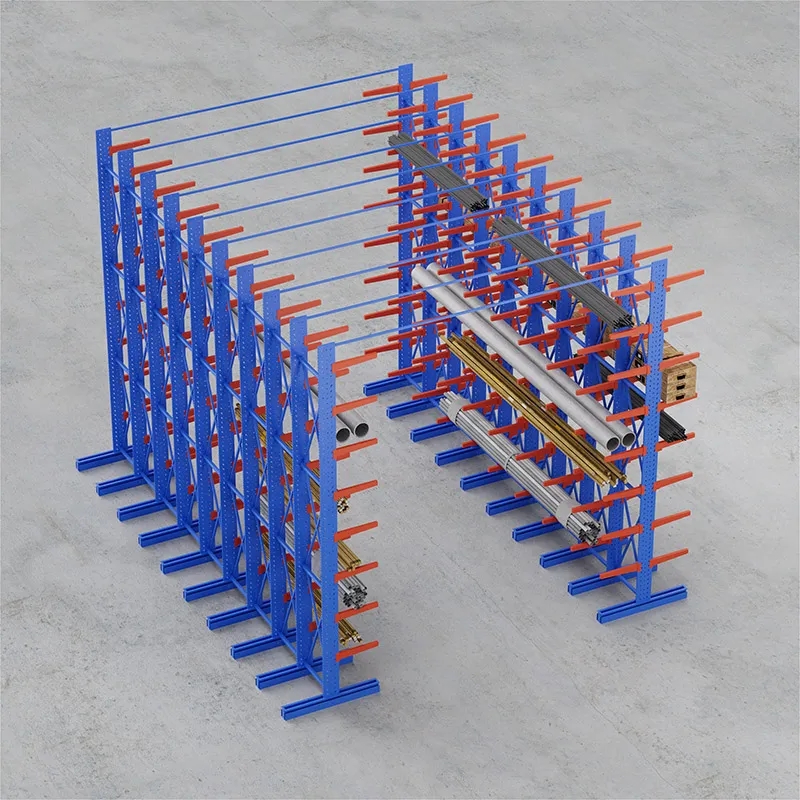

Best for long and irregularly shaped items such as exhaust pipes, body panels, and bumpers.

5. Mezzanine & Steel Platforms

Expand vertical space for spare parts distribution centers and service centers, enabling efficient picking zones.

6.Automated Storage & Retrieval Systems (AS/RS)

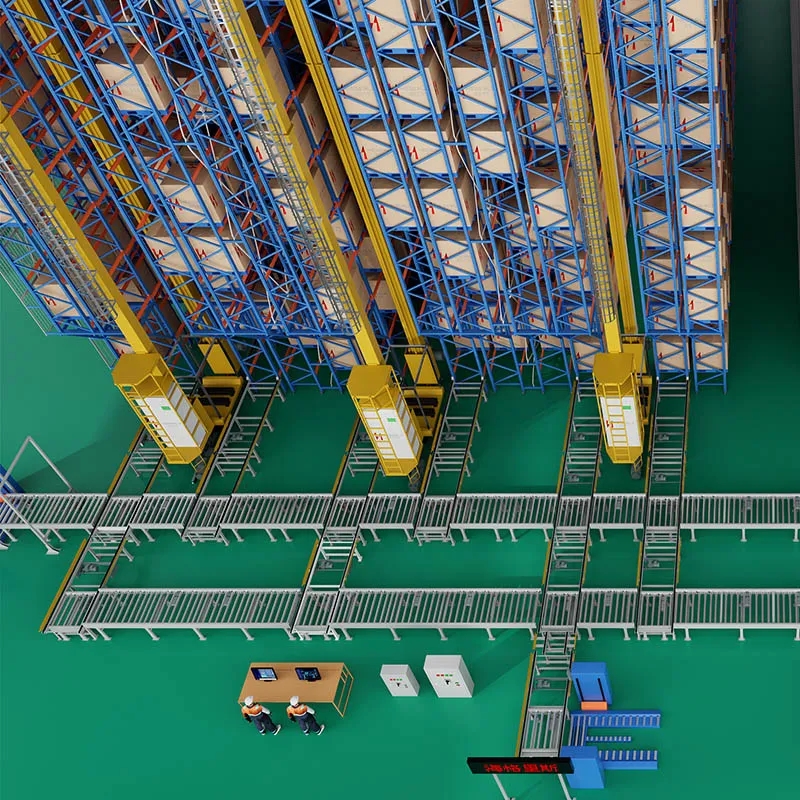

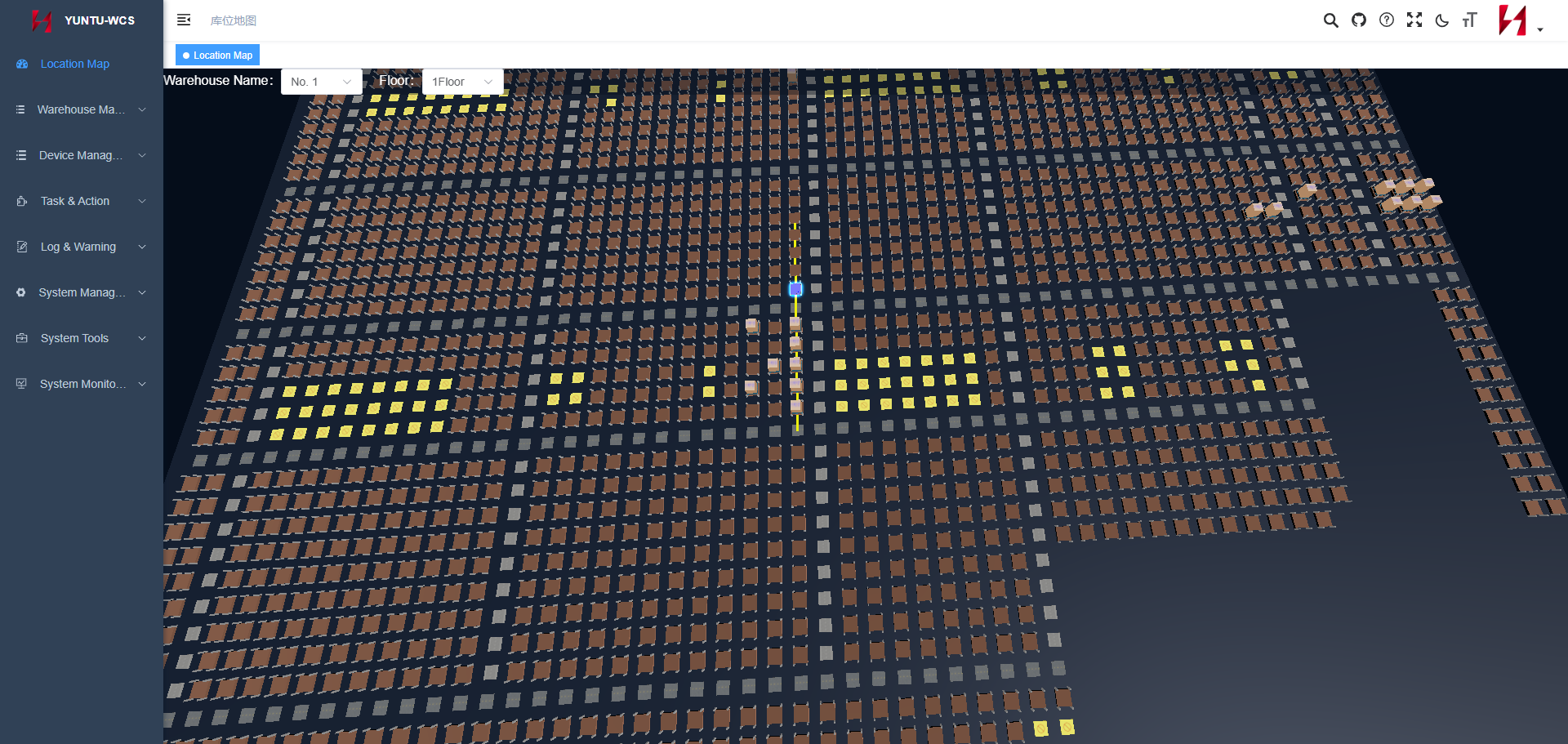

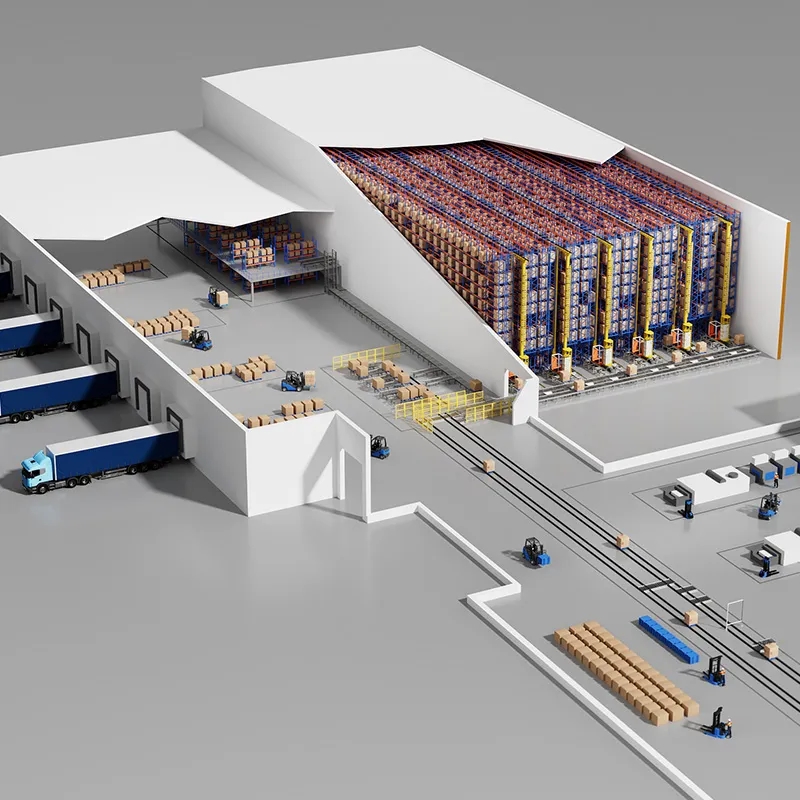

Integration with stacker cranes and conveyors for smart automotive logistics:

Faster throughput for high-volume operations.

Optimized space utilization up to 30–40%.

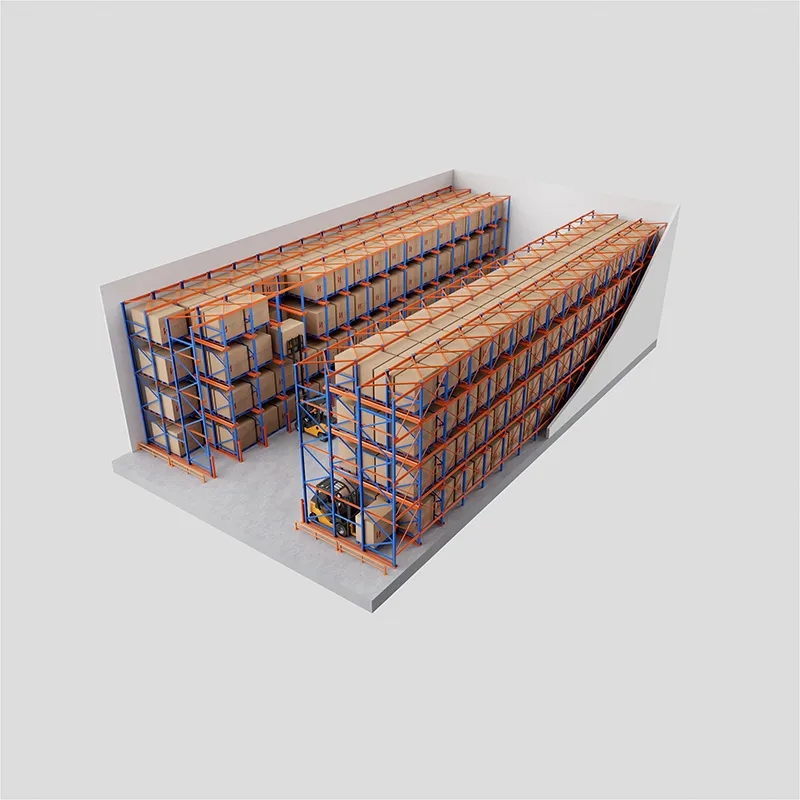

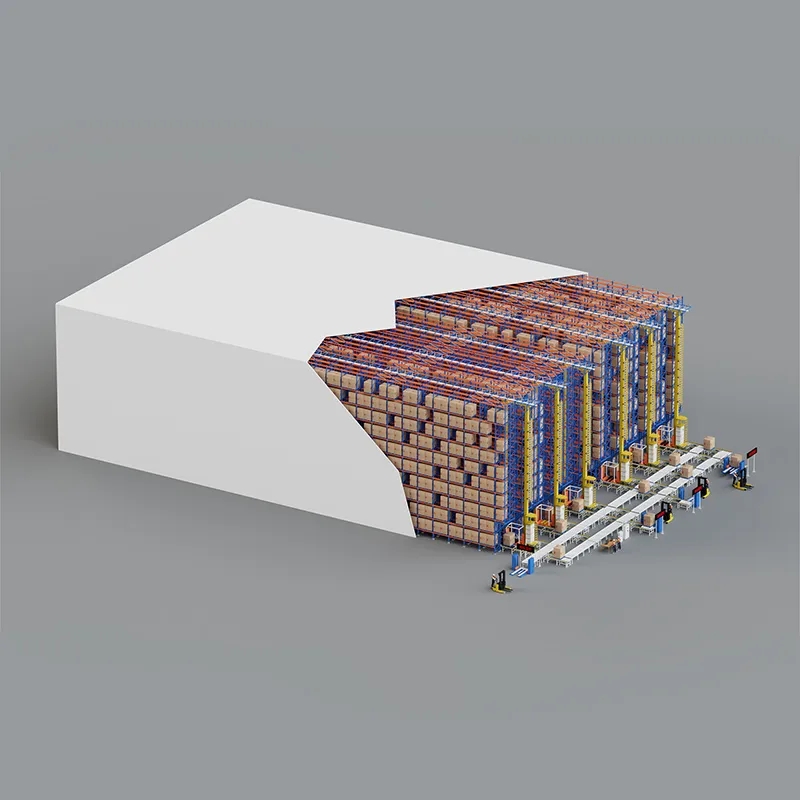

7.Rack Supported Warehouses (Clad Rack)

A self-supporting structure where the racking system forms both storage and building support.

Reduces construction costs by eliminating traditional building frameworks.

Allows high-bay warehouses up to 40m, maximizing cubic storage capacity.

Ideal for large automotive spare parts distribution centers and OEM supply hubs.

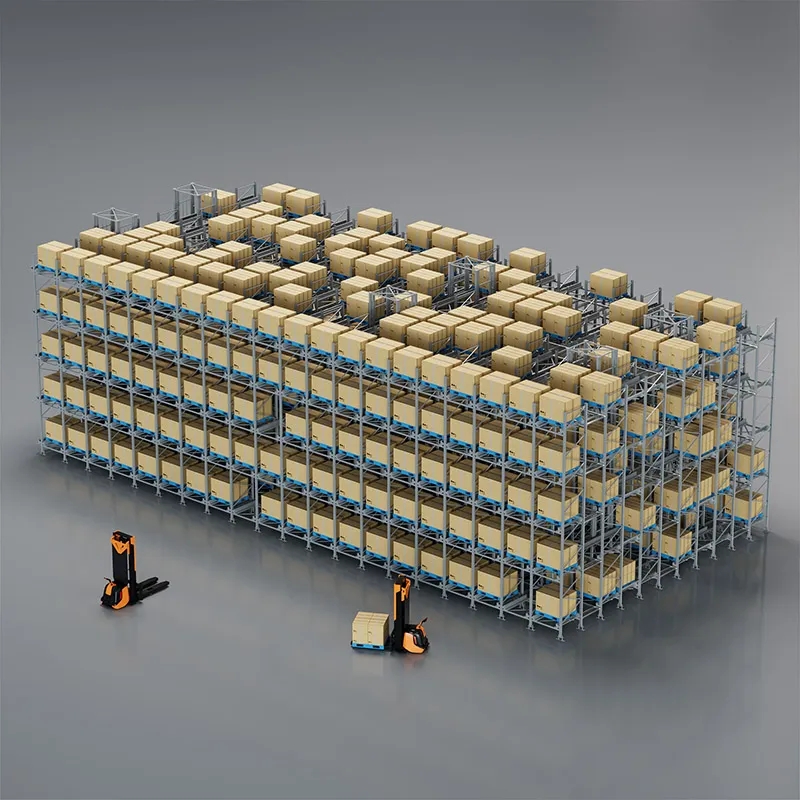

8.Shuttle Systems for Automotive Logistics

Runs along single aisles for semi-automated pallet storage and retrieval.

Increases efficiency compared to forklifts.

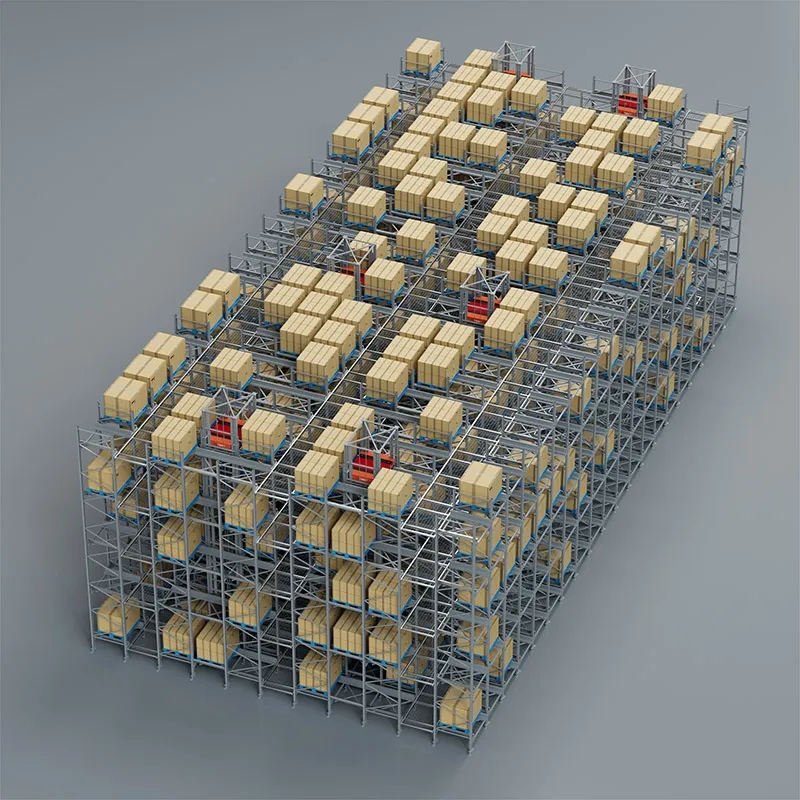

Moves horizontally and vertically within aisles.

Enables flexible, high-density storage for varied SKUs.

Perfect for tire warehouses and spare parts centers.

Moves in six directions (horizontal-vertical, front-back, left-right) for fully automated, multidimensional storage.

Integrates seamlessly with AS/RS and WMS for dynamic inventory handling.

Future-ready solution for large-scale automotive smart warehouses.

Key Features & Benefits

Strength & Durability – High-quality steel, anti-corrosion coating, and certified safety standards.

Flexibility – Modular systems that adapt to SKU changes and business growth.

Operational Efficiency – Faster picking and restocking reduce downtime.

Space Optimization – Increase storage capacity without costly building expansions.

Automation Ready – Future-proof designs compatible with robotics and shuttle systems.

Cost Savings – Reduced handling times and improved space usage lower operating costs.

Applications in the Automotive Supply Chain

Manufacturing Plants – Just-in-time supply of subassemblies and raw materials.

Tier 1 & Tier 2 Suppliers – Manage diverse inventories for OEM contracts.

Spare Parts Distribution Centers – Optimize high-frequency order picking.

Tire Warehouses & Retailers – Secure and organized tire storage.

Dealerships & Service Centers – Compact solutions for fast-moving parts.

E-commerce Automotive Parts – High-density storage for aftermarket online sales.

Case Study

Thailand A&S Automotive Seat Intelligent Warehouse

HEGERLS successfully implemented an ASAR warehouse with stacker crane systems for A&S Automotive Seat Company in Thailand.

Project Scope: Automated high-density storage for automotive seat components.

Solution: ASAR warehouse with stacker crane systems, lifts and WMS for real-time tracking.

Outcome:

Increased storage capacity by 60%.

Improved picking speed and assembly line responsiveness.

Reduced labor intensity and operational costs.

Enhanced accuracy in just-in-time part supply for automotive seat production.

This project showcases HEGERLS’ expertise in delivering turnkey intelligent warehousing solutions for the automotive sector.

BYD Fudi Battery Plant (Yancheng, China)

HEGERLS built an automated 3D warehouse for the BYD Fudi Battery Plant in Sheyang Economic Development Zone. The project stores and manages battery structural components with:

High bay rack structure to maximize vertical space.

AS/RS stacker cranes for high-frequency turnover.

Anti-static and fire-safe design meeting strict industry standards.

Result: Storage density increased by 60%, picking efficiency improved by 40%, and the warehouse now fully supports BYD’s just-in-time battery production.

Technical Specifications (Customization)

Rack Height: Customization (up to 40m with automated systems)

Upright Profiles: Various thicknesses for light to heavy loads

Surface Finish: Powder coating or hot-dip galvanizing

Optional Accessories: Wire mesh decking, safety locks, column guards, tire cradles, bin dividers

Why Choose HEGERLS?

Nearly 30 Years of Expertise in industrial storage and logistics equipment.

Trusted by Global Automotive Clients – from OEM factories to aftermarket parts distributors.

Customized Design & Engineering based on warehouse layouts and workflows.

End-to-End Service – Consultation, 3D simulation, installation, training, and after-sales support.

Scalable Solutions – From manual racks to fully automated smart warehouses.

HEGERLS is your trusted partner for automotive storage solutions that enhance efficiency, safety, and scalability.

Contact US Today for tailored automotive racking designs.