Drive-in Racking

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

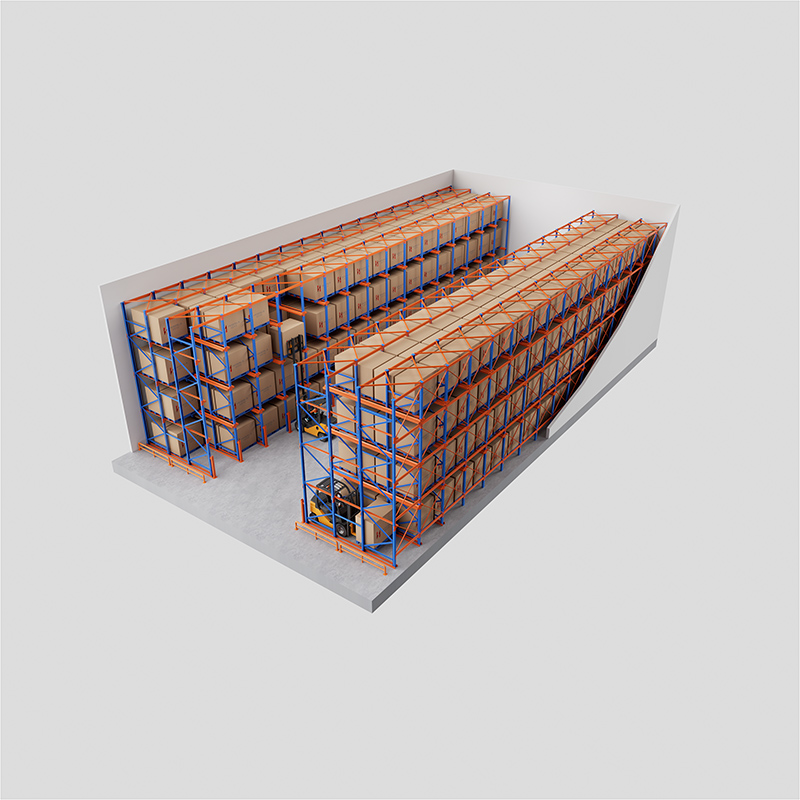

Drive-in racking is a high-density storage solution that can nearly double the storage capacity compared to conventional pallet racking within the same space. By eliminating aisles between each row and merging racks together, goods on the same level and in the same lane are stored back-to-back, maximizing warehouse capacity utilization. This system is especially suitable for storing large quantities of uniform, low-variety goods with standardized packaging, such as food, beverages, tobacco, and cold storage products.

Key Features of Drive-in/Drive–through Racks

High Space Utilization – By arranging only a few aisles and allowing forklifts to enter the racking lanes, warehouse utilization can reach up to 90%, and floor area utilization over 60%.

Bulk Storage for Low SKU Variety – Suitable for large volumes of the same type of goods, stored and retrieved in full pallet loads.

Last-In, First-Out (LIFO) Storage – Typical storage method where the last pallet loaded is the first to be retrieved.

Special Forklift Operation Requirements – Forklifts often operate in a continuous "high-lift" mode, which can raise the load's center of gravity and cause swaying if the aisle floor is uneven. This demands skilled operators to prevent collisions that could affect structural stability and safety.

Quality Determined by Design & Manufacturing – The racking's structural design is the most critical factor for performance. Material quality, production processes, manufacturing equipment, jigs and fixtures, and surface finishing (such as electrostatic powder coating) all directly impact durability and load-bearing capacity.

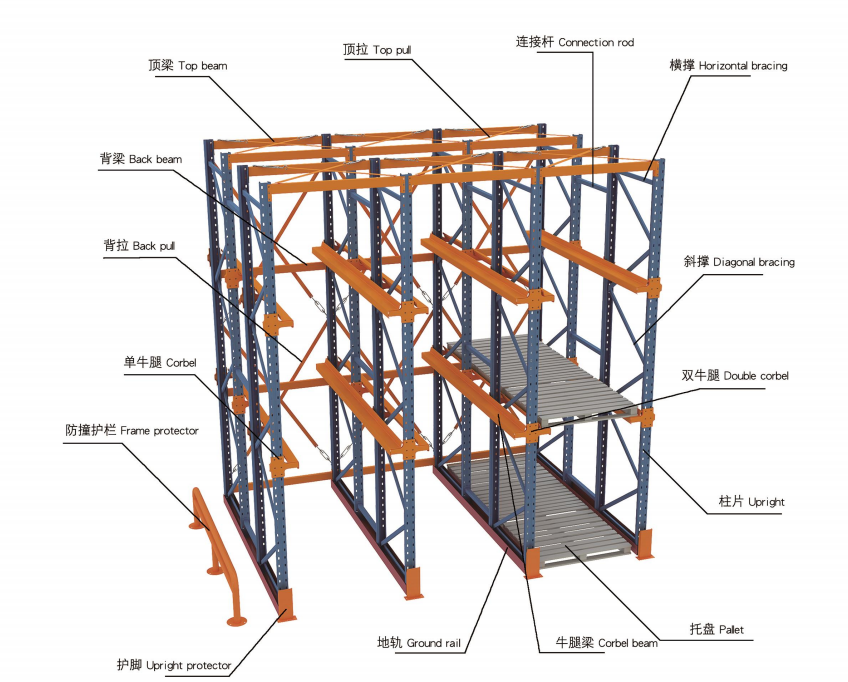

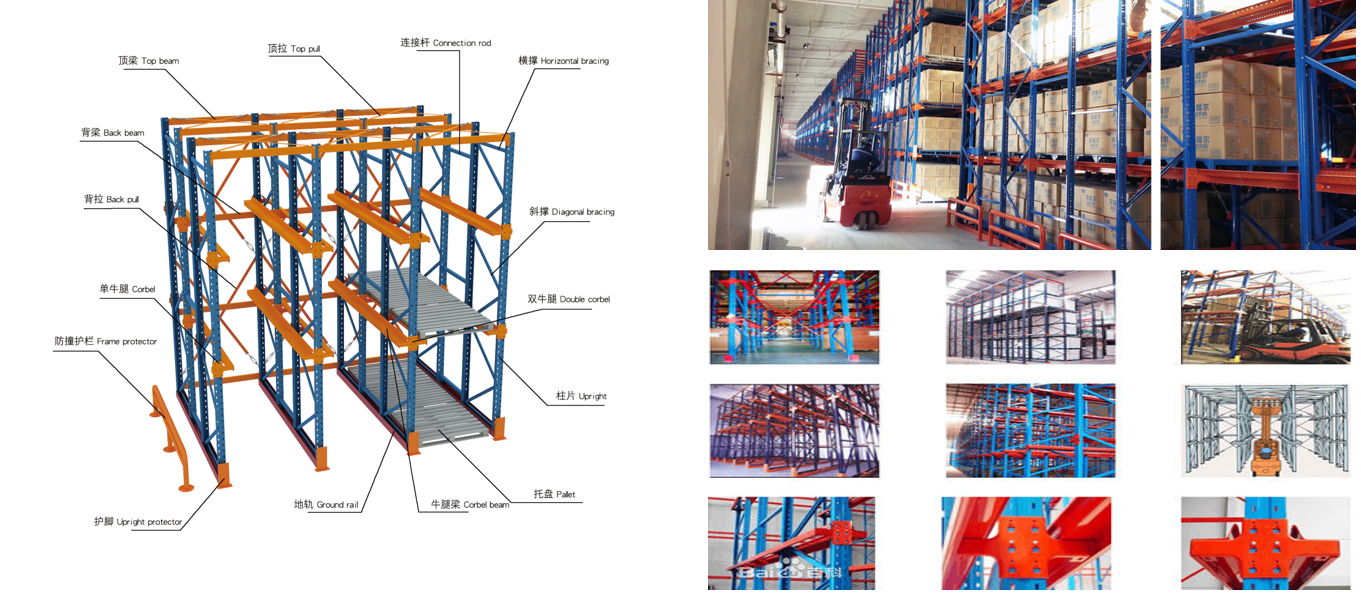

The Components & Safety Measures of HEGERLS Drive-in Racks

Due to the high-density storage nature of drive-in racking systems, structural stability is critical. This requires a greater number of components compared to conventional racking systems. Through the connection between the accessories and the rack upright frames, the goods can be safely and densely stored on the corbel beams, maximizing the utilization of space. The accessories of drive-in racks include:

Corbels – The main connecting parts between the corbel beams and the rack uprights, divided into single-sided and double-sided.

Corbel beams – The main supporting shelves for storing goods.

Top beams – The connecting and stabilizing parts of the rack uprights.

Top braces – The connecting and stabilizing parts of the rack uprights.

Back braces – The connecting and stabilizing parts of the rack uprights, used when the racks are arranged in a single direction.

Foot guards – The protective parts on the front of the racks.

Guard rails – Installed at the floor level inside the aisles to guide forklifts and protect the racking structure during pallet handling.

Application

Application

Design & Layout Guidelines

Drive-through racks can be divided into one-side and two-side access arrangements according to the picking direction.

One-side access racks – Installed against a wall, with pallets accessible from only one side. The total rack depth is recommended to be within 6 pallet positions to ensure efficient and reliable forklift operations.

Two-side access racks – Located in the middle of the warehouse with access from both ends. The total rack depth is recommended to be within 12 pallet positions for optimal performance.

In this type of rack system, the forklift operates in a continuous "lift high and operate high" mode, and the forklift is prone to shaking and hitting the racks, so it is crucial to fully consider the stability.

Overall Height – Should generally not exceed 10 meters to maintain structural safety.

Structural Reinforcement – Larger specifications and models are recommended, along with fixing devices to enhance stability.

Load Specifications –Single pallet load should not exceed 1,500 kg; Pallet span should not exceed 1.5 meters.

Forklift Types – Commonly paired with forward-moving battery forklifts or counterbalance battery forklifts.

Common Applications and Uses

Cold chain logistics

Beverage warehouses

Dairy and tobacco storage

Standardized appliance inventory

Garment manufacturing

Case Study

BIOPACK Company Warehouse Drive-In Rack System Project

Customers Reviews

The drive in racking has made great use of our available space and significantly increased our storage capacity. We've boosted our warehousing capacity by over 50 %.

Compared with pallet racking, the drive-in racking has reduced the aisle occupation by 70%, and the storage capacity of the same - area warehouse has increased by 58%. This is a great help for companies like us with high warehouse rents.

Drive in racking is more affordable to install and maintain compared to automated systems. It provides a high return on investment for businesses storing large quanities of similar goods.

Why Choose HEGERLS Drive-In Racking?

30 years of racking design and export experience

ISO-certified manufacturing process

Professional engineering team for layout optimization

Fast delivery & global project support

OEM/ODM available

FAQ

What Is a Drive-In Racking System?

Drive-in racking is a high-density storage solution designed for warehouses with large volumes of similar palletized goods. It allows forklifts to drive directly into the rack structure to deposit or retrieve pallets from support rails. This system follows the Last-In-First-Out (LIFO) inventory principle and is ideal for environments where space utilization is more critical than product rotation.

What's the difference between drive-in and drive-through racking?

Drive-in racking has forklift access from one side only and operates on LIFO logic, while drive-through racking allows access from both sides and supports FIFO inventory flow.

Can I customize the drive-in racking system?

Yes. HEGERLS offers fully customizable solutions including size, load capacity, surface coating, and safety accessories.

Request a Free Quote?

Looking for a compact and cost-effective pallet storage solution? Contact HEGERLS now to get a tailored racking design for your warehouse.