Gravity Flow Rack

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

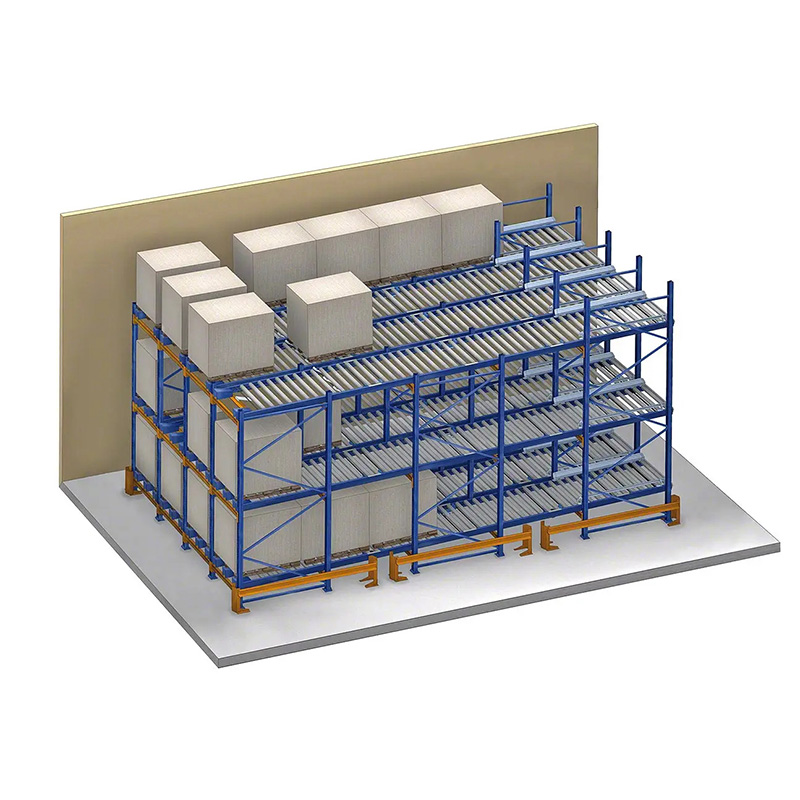

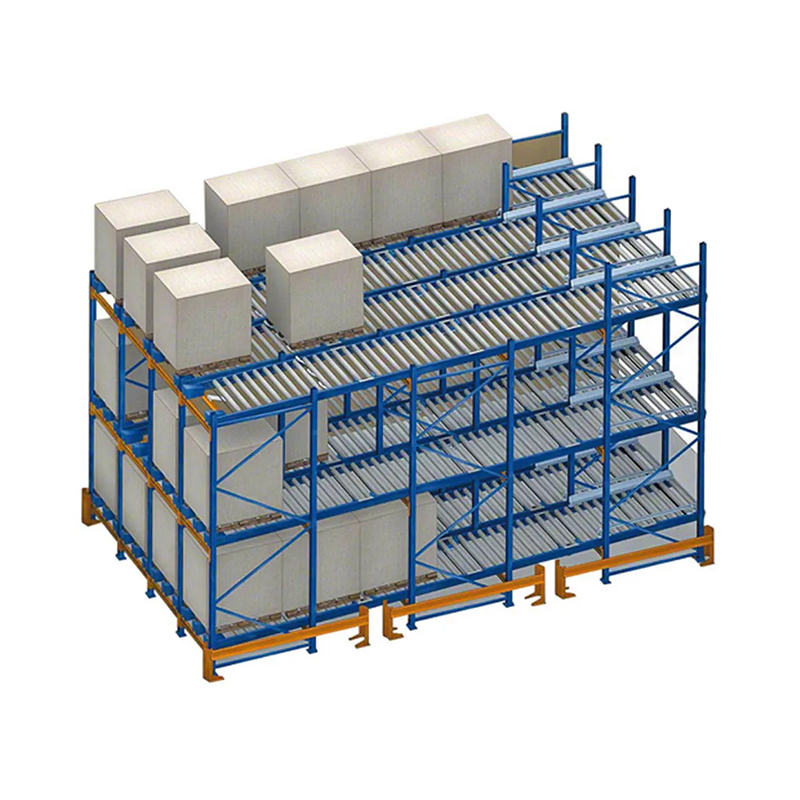

The Gravity Flow Rack is composed of upright post sets, load-bearing beams, rollers, damping rollers, and buffer separators. The most appropriate inclination angle is determined based on the friction coefficient of pallets and the flexibility of rollers. The Gravity Flow Rack features advantages such as "first-in-first-out (FIFO), high utilization rate, integration of storage and transportation, safety and high efficiency".

The Gravity Flow Rack adopts a roller-seat design and is appropriately tilted. It utilizes the self - weight of goods to drive the flow. Pallets are densely stored and in an optimal physical cycle, achieving the FIFO logistics effect. It is a dense-storage warehouse system that can make full use of the warehouse area, increasing the area utilization rate by approximately 30% compared to ordinary fixed-type racks.

It is especially suitable for storing goods with a high turnover rate that require FIFO, such as applications in breweries, food factories, and various production lines.

Textiles, Shoes and Apparel

Working Principle of Gravity Flow Rack

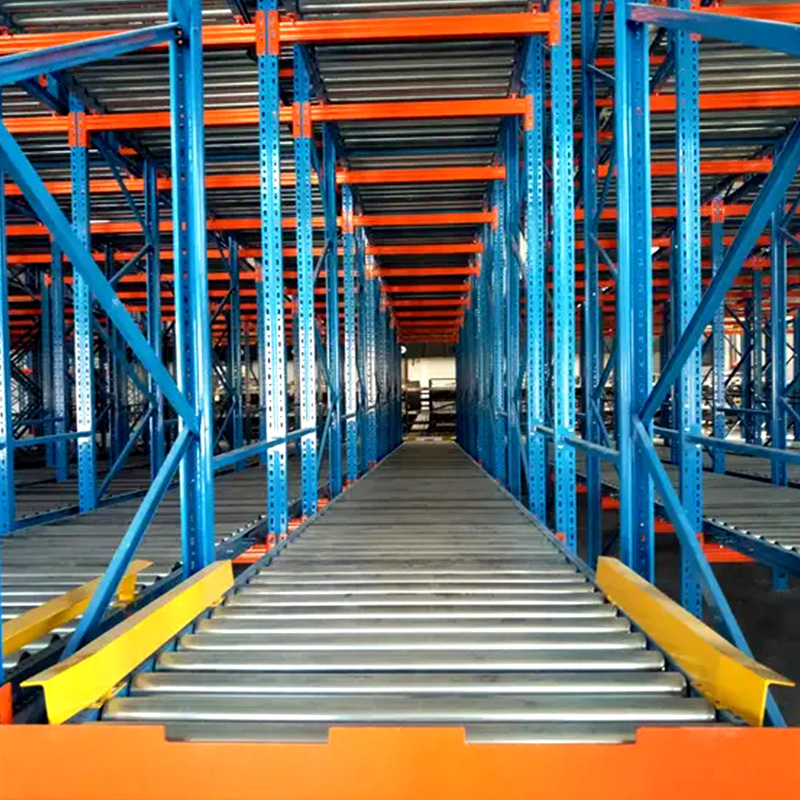

The loading channels are fixed on the rack beams at a certain inclination angle. Pallets are placed from the higher end and slide down along the roller track by their own gravity.

To control the sliding speed and avoid collisions, a resistance system is set at regular intervals on the loading channels. The faster the pallet slides, the greater the resistance generated by the system.

A terminal separation mechanism is installed at the lower end to separate the two adjacent pallets at the bottom, allowing the lowest pallet to be smoothly retrieved.

Features of Gravity Flow Rack

High throughput: The Gravity Flow Rack allows simultaneous storage and retrieval of goods, accelerating inventory turnover.

Strict FIFO (First-In-First-Out) compliance: Goods flow in the order of storage time, enforced by the rack design. The storage area requires only two separate channels for inbound and outbound operations, eliminating safety hazards from cross-task interference.

Pallet-based storage optimization: Suitable for palletized goods, it provides an efficient solution for storing large and heavy items. Warehouse space utilization exceeds 75%, requiring only one access channel.

Eco-friendly operation: Fully non-powered, energy-free, low-noise, and safe for full-load operation.

Lower investment & shorter lead time: Costs less than automated warehouses (three-dimensional warehouses) and has a shorter manufacturing cycle.

High-density storage capacity: As a type of dense racking, it enables large-scale intensive storage. Compared to mobile racks, it can accommodate items from lightweight goods (below 1kg) to pallets and small containers. With reduced aisle numbers, it saves up to 50% warehouse space compared to conventional racks.

Reduced handling distance: Fixed in/out positions shorten the travel distance of forklifts and handling equipment by 1/3, minimizing route planning complexity and error risks.

Separate operation zones: Inbound and outbound tasks are fully segregated.

Absolute FIFO guarantee: Meets modern warehouse management standards by ensuring chronological inventory rotation.

Picking-friendly design: Compared to general racks, it narrows the operation area, making it a key solution for order picking—especially in storage-type picking systems.

Application Fields

E-commerce Logistics

Food and Dairy Beverages

Frozen and Refrigerated Storage

Textiles, Shoes and Apparel

Furniture and Home Appliances

Pharmaceutical and Chemical Industry

Equipment Manufacturing

Pharmaceutical and Chemical Industry

Military Supplies

Commercial Circulation

Why Choose HEGERLS Gravity Flow Rack?

Nearly 30 Years of Expertise in intelligent warehousing and storage solutions.

Custom-Engineered Designs to match your warehouse layout and operational needs.

Reliable Quality backed by international certifications and advanced manufacturing.

Global Projects Experience with proven solutions in logistics, e-commerce, food & beverage, and manufacturing industries.

Upgrade your warehouse with our Gravity Flow Rack and experience greater efficiency, lower costs, and smarter inventory management. Contact us today!