Flow Rack

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

Flow racks can save space and improve efficiency, making them suitable for storing and picking a large number of goods. They can be equipped with electronic tags to easily achieve information management of goods.

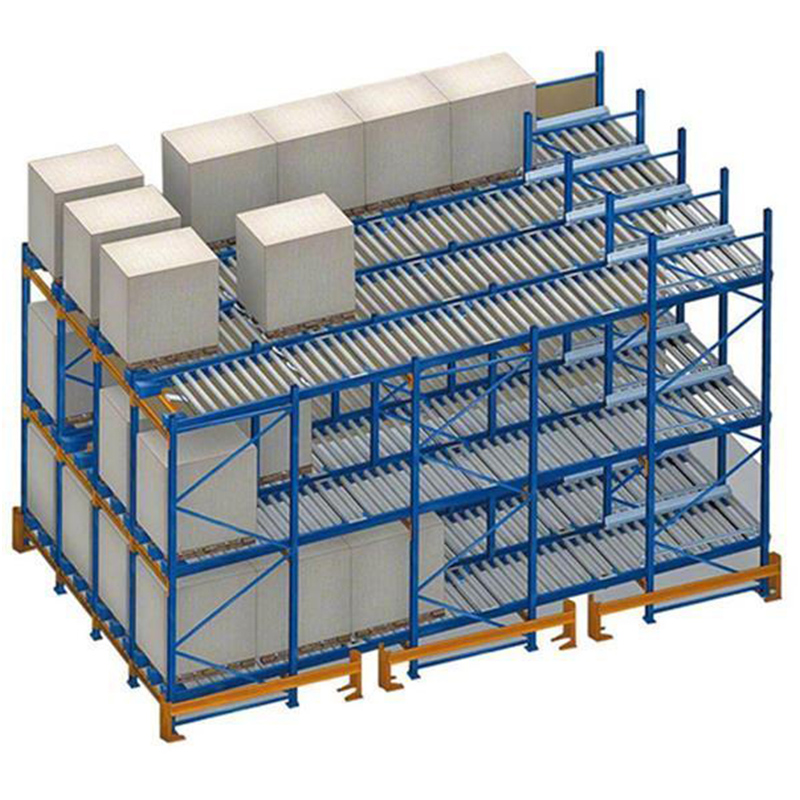

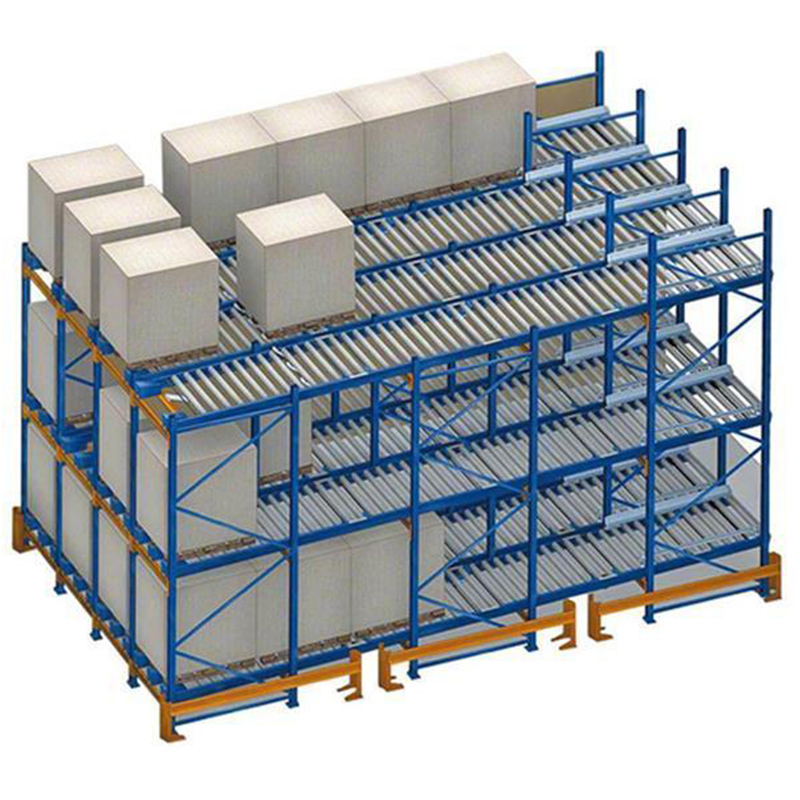

The flow bars of flow racks are directly connected to the front and rear crossbeams and intermediate support beams, and the crossbeams are directly hung on the columns. The installation inclination of the flow bars depends on the size and weight of the cargo boxes as well as the depth of the flow rack, typically ranging from 5% to 9%.

The load-bearing capacity of each flow bar roller is 6kg. When the goods are heavy, 3 to 4 flow bars can be installed in one runway. Usually, a support crossbeam is installed every 0.6m in the depth direction to increase the stiffness of the flow bars. When the runway is long, a partition plate can be used to separate the runway. A brake pad should be installed at the picking end to decelerate the goods and reduce impact.

Working Principle of Flow Racking

The sliding composite pipe rack is equipped with sliding rails. Relying on the sliding property and inclination of the rails, as well as the gravity of the materials themselves, the materials can slide automatically. Goods are placed on the rollers at the upper end of the sloped slideway, and they slide down automatically under the action of gravity. One side of the channel is used for storing goods, while the other side is for picking. This allows for First-In-First-Out (FIFO) management and enables multiple picking operations after a single replenishment.

Types of Flow Rack Systems

HEGERLS offers a variety of Flow Rack designs to meet different storage and picking requirements:

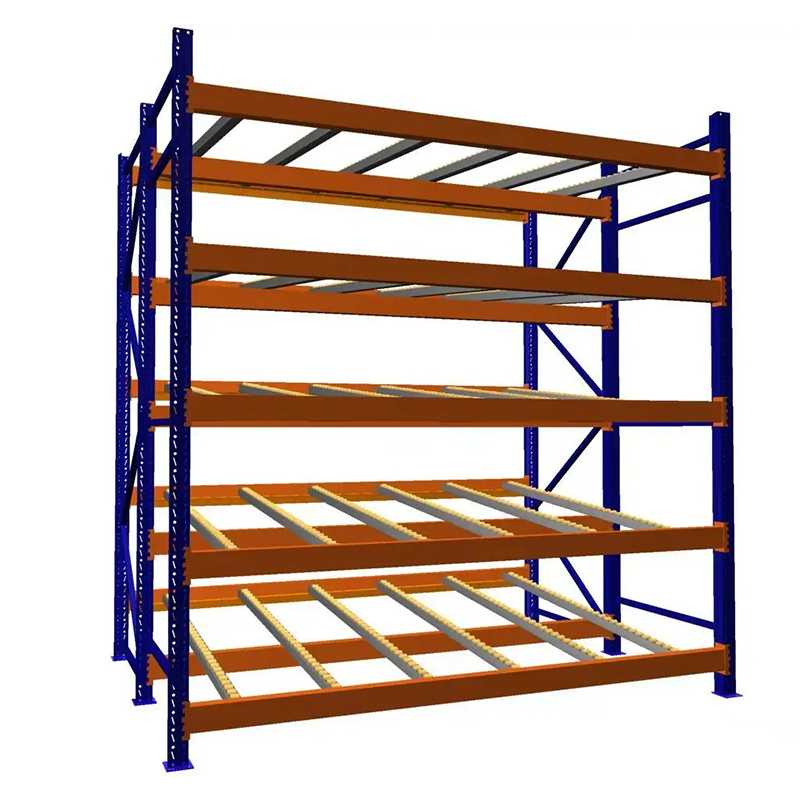

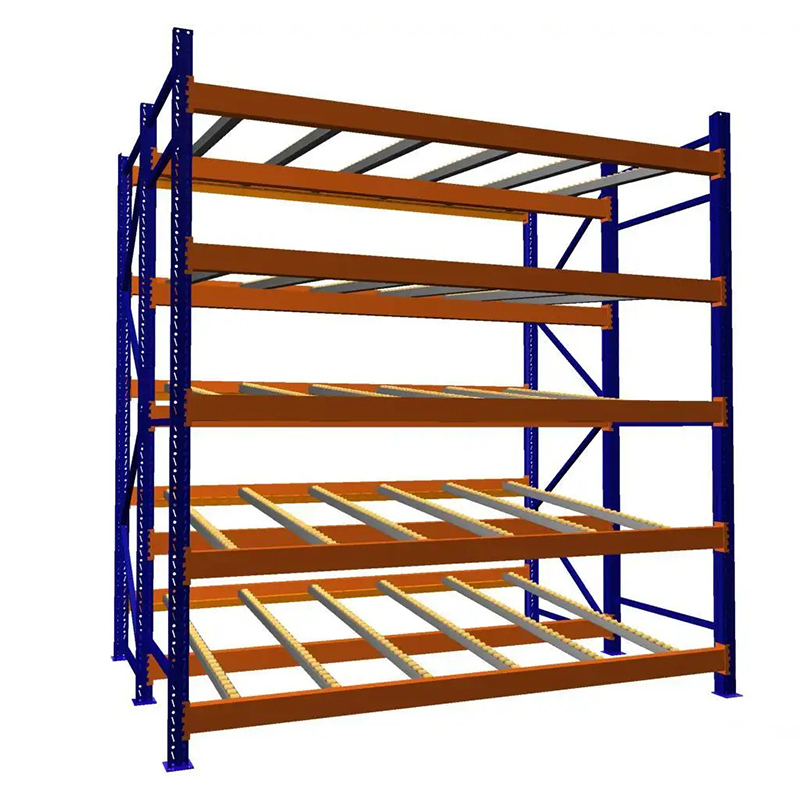

1. Carton Flow Rack

Designed for cartons, bins, and totes.

Commonly used in order picking zones and e-commerce warehouses.

Roller or wheel bed tracks for smooth carton movement.

2. Pallet Flow Rack

Suitable for palletized goods.

Heavy-duty rollers support high load capacity.

Ideal for cold storage and high-throughput distribution centers.

3. Gravity Flow Rack

Uses a slight incline to move items forward by gravity.

FIFO ensures efficient inventory rotation.

Low energy consumption, as no power is required.

4. Inclined Shelf Flow Rack

Adjustable slope for different product sizes.

Common in assembly lines for quick component replenishment.

5. Integrated Flow Rack with Picking Workstation

Combines flow rack storage with a picking or packing station.

Improves ergonomic access and speeds up order fulfillment.

Don't know how to choose the right type? Don't worry, HEGERLS engineers can design custom solutions, such as multi-level flow racks, mobile flow racks, or integrate them with AS/RS systems for maximum efficiency.

Contact us today to get a free design consultation and quote.

Applications

E-commerce Fulfillment Centers – Fast-moving SKUs with high order volumes.

Manufacturing Supply Lines – Continuous supply of components for assembly lines.

Food & Beverage Warehouses – FIFO storage to maintain product freshness.

Pharmaceutical Distribution – Organized storage for medicines and healthcare products.

Why Choose HEGERLS Flow Rack?

30 years of warehouse storage expertise

Customized engineering solutions for specific industries

High-quality materials and strict quality control

Global service network with installation and maintenance support