Cantilever Racking

- HEGERLS

- Xinhe Industrial Park, Hebei, China

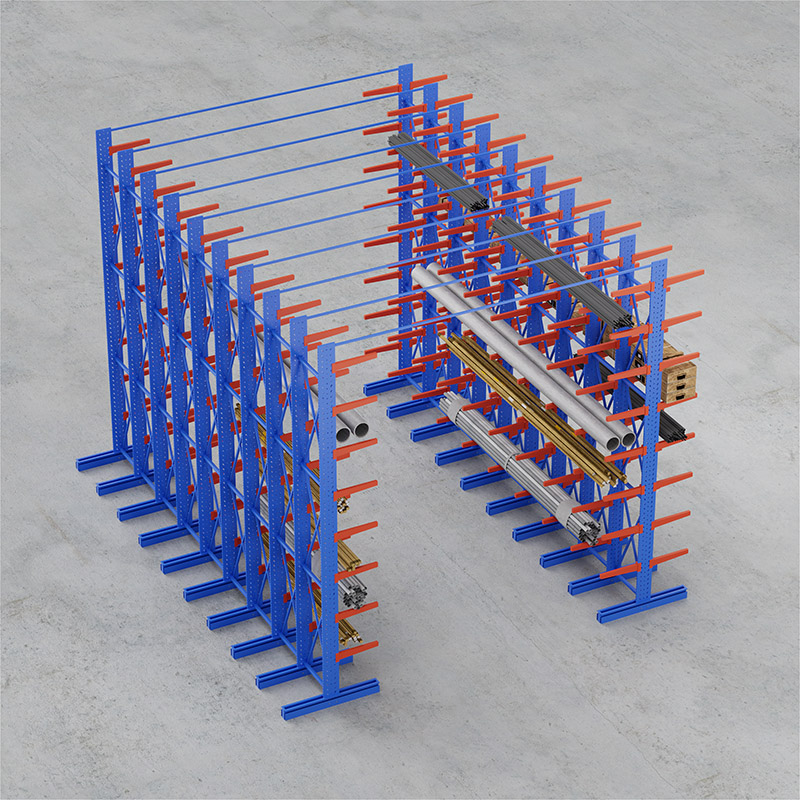

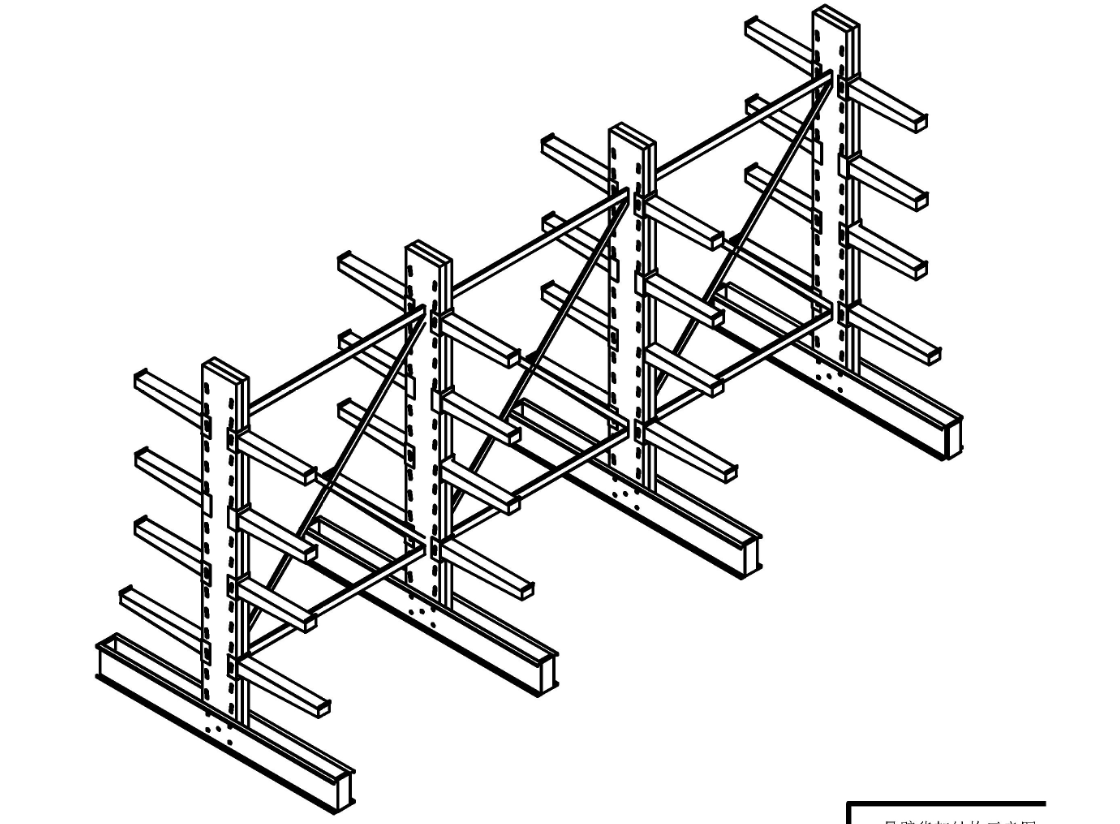

Cantilever Racking Structure & Materials

Uprights: Made from high-strength H-beams or specially designed cold-rolled C-section steel profiles, welded back-to-back for enhanced load-bearing capacity.

Arms: Constructed from square tubes, cold-rolled steel, or H-beams. Arm connections are either plug-in or bolted to suit operational needs.

Base: Made from H-beams or custom profiles, securely bolted to the uprights and anchored to the ground using expansion bolts.

Back Braces: Diagonal and horizontal braces enhances the system's stability and load resistance.

Key Features of HEGERLS Cantilever Racks

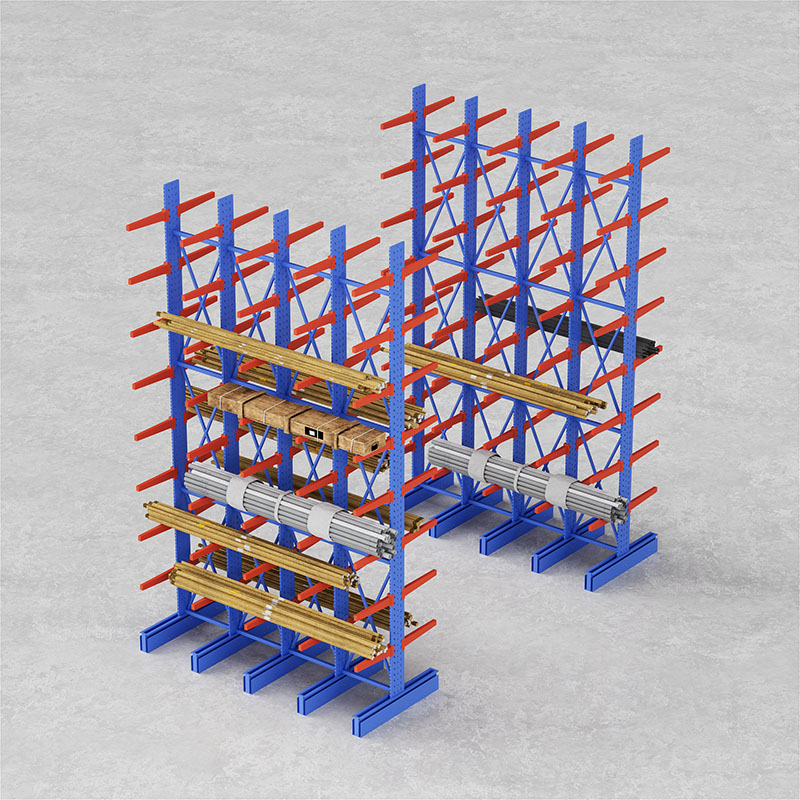

Ideal for Long and Irregular Items

Specifically designed for storing long-shaped, circular, plate-type, and irregular heavy materials

Suitable for items such as steel pipes, wood planks, aluminum profiles, and furniture components

High Load Capacity & Flexibility

Cantilever arm length: 1.0 – 1.2 meters

Loading capacity per arm: up to 1 ton

Maximum column height: 10 meters

Available in light, medium, and heavy-duty versions

Customizable Configuration

Fully customizable to meet specific warehouse layouts and storage needs

Optional steel or wooden decking on arms for handling non-long goods

Center column design creates unlimited horizontal space

Indoor & Outdoor Use

Optional hot-dip galvanized surface for outdoor environments

Can be installed with roofing or canopy to protect from wind, rain, and sunlight

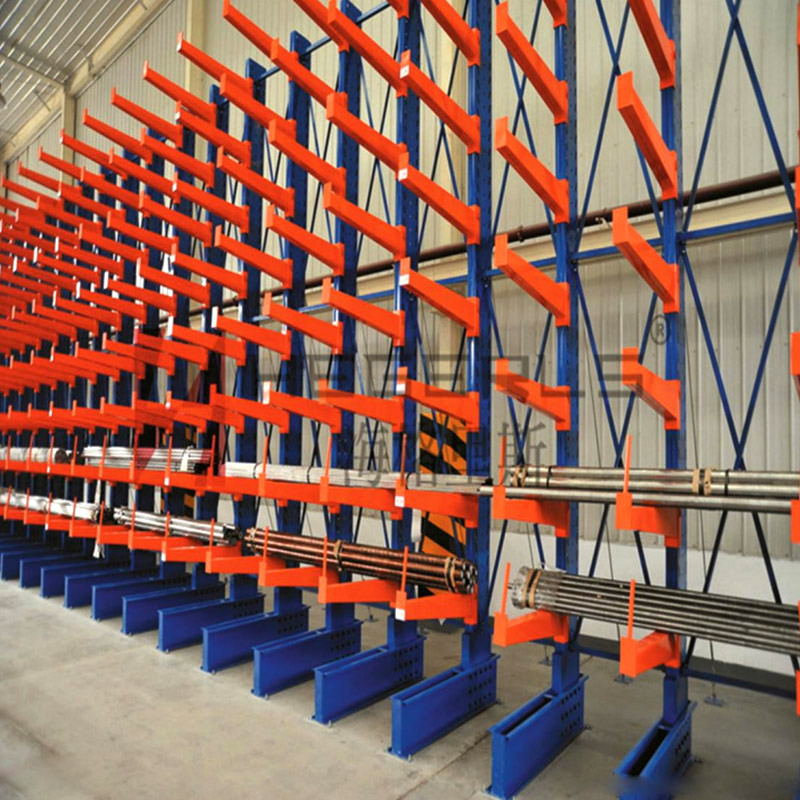

Efficient Loading & Unloading

Supports use with side-loading forklifts and other specialized equipment

Provides easy visual inventory access and fast loading/unloading operations

Ideal for narrow aisles and low-ceiling warehouses

Excellent Structural Stability

Large and heavy base design improves overall stability

Strong connection between uprights and cantilever arms ensures long-term safety

Designed to meet standard and seismic application requirements

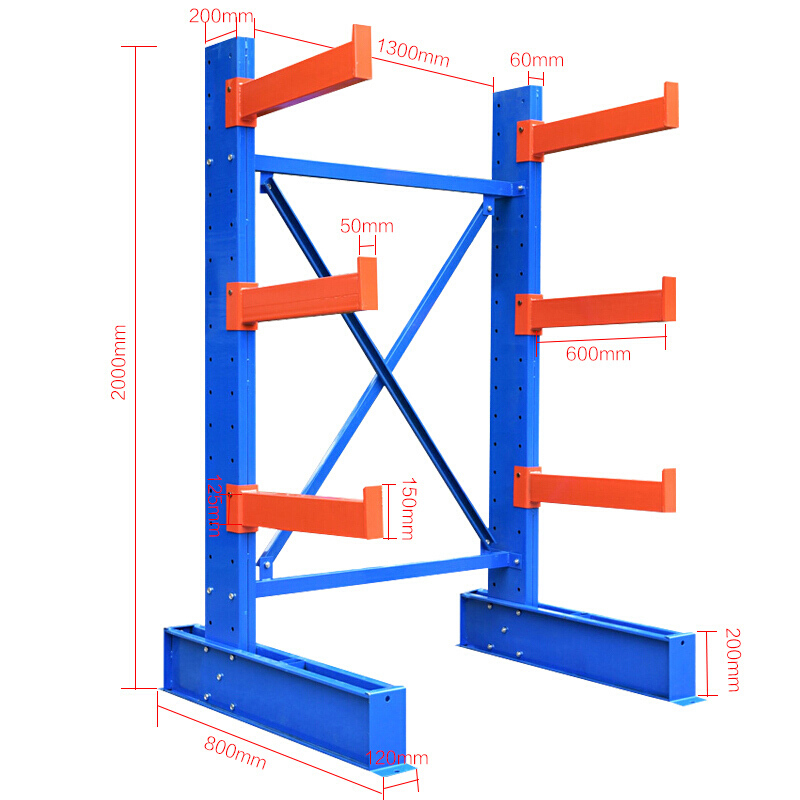

It is suitable for MDF and tube storage. The loading of each arm could reach 1000kgs.

The height of post could reach 10m high.

The color could be customized. We have color of blue and orange. It could also be customized.

the holes are formed by laser cutting. It is exactly.

Load Classifications

Cantilever racking systems are available in three types based on loading capacity:

Light-Duty: For loads up to 300 kg per arm, ideal for lightweight pipes or wood.

Medium-Duty: For loads up to 600 kg per arm.

Heavy-Duty: For heavy loads up to 1,500 kg per arm and up to 3,000 kg per upright.

Note: Arms are vertically adjustable in 100mm increments for flexible storage configuration.

Typical Specifications (Reference)

Type | Upright Specs (mm) | Upright Height (mm) | Arm Specs (mm) | Arm Length (mm) | Load per Arm (kg) |

Light-Duty | 50×100×2.0 | ≤1800 | 40×60×1.5 | ≤700 | ≤150 |

60×120×2.0 | ≤2000 | 40×80×1.5 | ≤1000 | ≤250 | |

40×80×1.5 | ≤300 | ||||

Medium-Duty | 70×140×2.0 | ≤2500 | 50×100×2.0 | ≤1100 | ≤350 |

50×120×1.5 | ≤400 | ||||

50×120×2.0 | ≤450 | ||||

80×180×2.0 | ≤3000 | 50×140×1.5 | ≤1200 | ≤500 | |

50×140×2.0 | ≤600 | ||||

Heavy-Duty | 100×200×2.5 | ≤3500 | 100×100×2.0 | ≤1300 | ≤1000 |

60×160×2.0 | ≤1500 |

Application Scenarios

Wood and timber yards

Pipe and tubing storage

Steel and metal fabricators

Furniture warehouses

Building material distribution centers

Irregular goods storage

This racking system is compatible with forklifts, side-loading trucks, cranes, or manual handling depending on your warehouse operation mode.

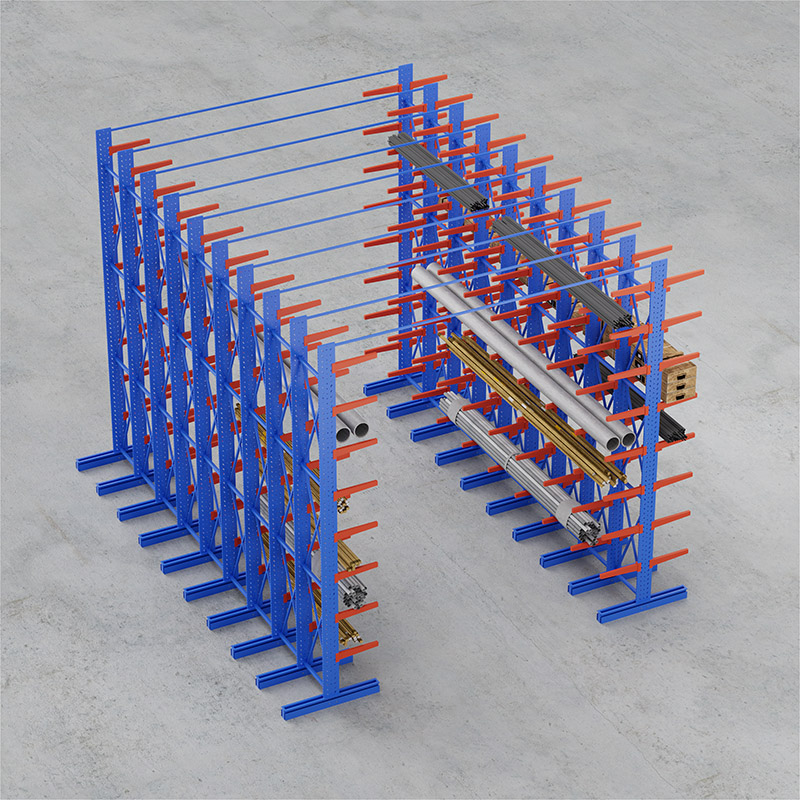

Case Study

GJ Electrical | Customized Heavy-Duty Cantilever Racking Project

To efficiently store long and irregular electrical components such as cable reels, metal conduits, and panel materials, GJ Electrical, a leading manufacturer of industrial electrical equipment, partnered with HEGERLS to implement a heavy-duty cantilever racking system.

The project was customized based on GJ’s specific storage requirements and limited warehouse space. HEGERLS provided a tailored racking system featuring:

Double-sided cantilever arms for maximum space usage

Hot-dip galvanized surface treatment for enhanced durability

1.2m arm length, with each arm supporting up to 1 ton of load

This project enabled GJ Electrical to modernize their warehouse layout while meeting the high-frequency demands of industrial order fulfillment.

FAQ

What are cantilever racks?

Cantilever racks are a type of warehouse racking system designed to store long, bulky, or irregularly shaped items such as pipes, lumber, steel bars, and furniture. Unlike traditional pallet racking, cantilever racks use horizontal arms that extend from vertical columns to hold the load, offering easy access and flexible storage without front obstructions.

Does cantilever racking need to be bolted down?

Yes, cantilever racks must be securely bolted to the floor to ensure stability and safety, especially under heavy loads or forklift operation. The base of the rack is typically anchored using expansion bolts or chemical anchors to prevent tipping or shifting during loading and unloading.

What are the Limitations of Cantilever Racks?

The cantilever racks are designed exclusively for long or rolled items such as lumber, pipes, or coils.

Requires handling equipment with wide fork spacing, such as side-loading forklifts.

Height is typically limited to below 6 meters due to structural and operational considerations.

Lower space utilization, generally ranging from 35% to 50% compared to other racking systems.

Storage type is specific, mainly for long, narrow, or cylindrical goods.

What is the difference between a cantilever rack and a pallet rack?

The key difference lies in what they are designed to store and how they are structured:

Cantilever racks are open-front systems ideal for long or awkward items like pipes and timber. They use extended arms instead of shelves.

Pallet racks are enclosed systems designed for palletized goods, with horizontal beams supporting pallet loads across multiple levels.

How to choose the right cantilever racking manufacturer?

When selecting a cantilever racking manufacturer, consider the following:

Engineering capability: Can they provide custom solutions for your material types, weight, and warehouse layout?

Material quality: Look for manufacturers using high-grade steel and certified production processes.

Load testing & safety: Ensure they follow international safety standards and provide test data.

After-sales support: Choose a supplier that offers installation guidance, maintenance support, and long-term service.

Experience: A manufacturer with a proven track record in your industry (e.g., construction, metal fabrication, furniture) is often more reliable.

HEGERLS offers customizable cantilever racking systems backed by almost 30 years of experience in material handling and warehouse storage solutions. We have production base, R&D base, and headquarters in China, and can offer one-stop warehouse storage solutions. Contact us for more information.

Looking for a solution for long or irregular-shaped goods?

HEGERLS Cantilever Racking offers strength, flexibility, and efficiency — all in one system. Contact us today to customize your racking system based on your storage needs.