Mezzanine Racking

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Product Introduction

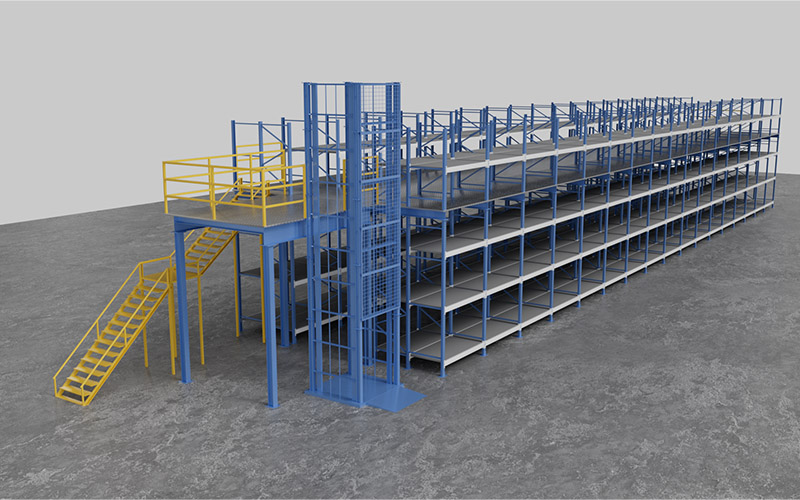

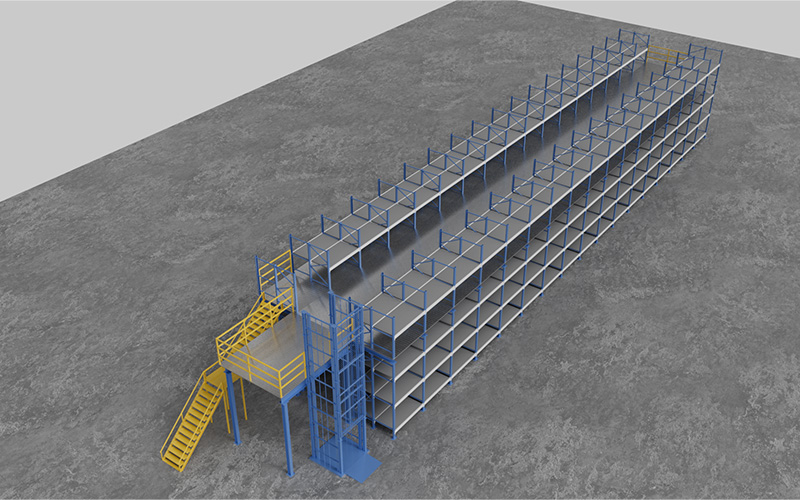

Mezzanine racking is a multi-tier storage system, typically two levels or more, constructed from high-quality steel profiles and composed of uprights, support beams, flooring panels, stairs, guardrails, and shelving. It can be equipped with trolleys, staircases, lifts, chutes, conveyors, and lighting systems to streamline order picking operations. This design maximizes the use of vertical warehouse space, significantly improving storage capacity and operational efficiency.

Types of Mezzanine Racking

| Type | Description | Applications |

| Free-Standing Mezzanine | Independent steel structure not connected to racks | Flexible layouts, offices, assembly areas |

| Rack-Supported Mezzanine | Built on top of pallet racking | High-density storage, order picking |

| Shelving-Supported Mezzanine | Uses shelving as support | Small parts storage, e-commerce picking |

Key Features

High Space Utilization – Optimize vertical space to increase storage capacity without increasing your footprint.

Modular & Customizable Design – Flexible configurations to fit any warehouse layout, load requirement, or workflow.

Versatile Flooring Options – Available in flat steel panels, checkered steel plates, or perforated steel panels to meet different requirements such as fire protection, ventilation, and lighting.

Quick Installation & Easy Relocation – Minimal disruption to ongoing operations, and can be disassembled or relocated.

Safety Compliance – Equipped with guardrails, safety gates, anti-slip staircases, and compliant with OSHA/ANSI standards.

Flexible Material Handling – Goods can be moved between floors by forklift, hydraulic lift, or freight elevator, and transferred on the same floor using hand trolleys.

Wide Application – Suitable for storing a wide variety of goods, from small parts to medium-sized cartons.

Prodection Details

Rack Dimensions

Shelf Panel Options: Mesh panels

Shelf Panel Options: Strip-shaped galvanized panels

Shelf Panel Options: Large-size powder-coated panels

Technical Specifications

Load Capacity per Floor: Customized up to 1,000 kg/m²

Height: Customized according to warehouse space

Flooring Options: Hot-rolled steel, checkered steel plate, steel grating

Safety Features: Guardrails, staircases, electric or manual lifts, lighting systems

Finish: Powder-coated in customer-specified color

Design Considerations for Drive-Through&Flat Mezzanines

Rack Dimensions

Width (W):

55-type uprights: 1050 mm, 1250 mm, 1550 mm, 1850 mm, 2010 mm, 2050 mm

80-type uprights: 1303 mm, 1603 mm, 1903 mm, 2053 mm, 2103 mm

Depth (D): 400 mm, 500 mm, 600 mm, 700 mm, 800 mm

Height (H):

For both 55-type and 80-type uprights, height should be in multiples of 50 mm

According to the specifications of the stored goods.

Number of Shelf Layers:

Generally 3 to 6 layers, determined by product size, weight, and handling method

Define whether the top shelf is for storage or serves as a dust barrier

Shelf Load Capacity:

100 kg to 1000 kg per layer, depending on goods and shelf specifications

Floor Load Capacity:

300 kg/m² to 1000 kg/m², based on stored goods and handling equipment

Shelf Panel Options:

Strip-shaped galvanized panels (0.7 mm)

Large-size powder-coated panels (0.7 mm)

Mesh panels

Floor Height Options

Common heights: 2200 mm, 2400 mm, 2600 mm, 2800 mm, 3000 mm, 3200 mm

Selection is based on warehouse clear height, handling equipment, lighting, and fire protection requirements.

Passage Width

Manual picking: ≥ 800 mm

Flat cart picking: ≥ 1000 mm

Hydraulic pallet truck picking: ≥ 1800 mm

Main passages must allow two-way traffic

Guardrails & Kickboards

Guardrails installed on the outer side of passages, height 1200 mm, with three horizontal bars

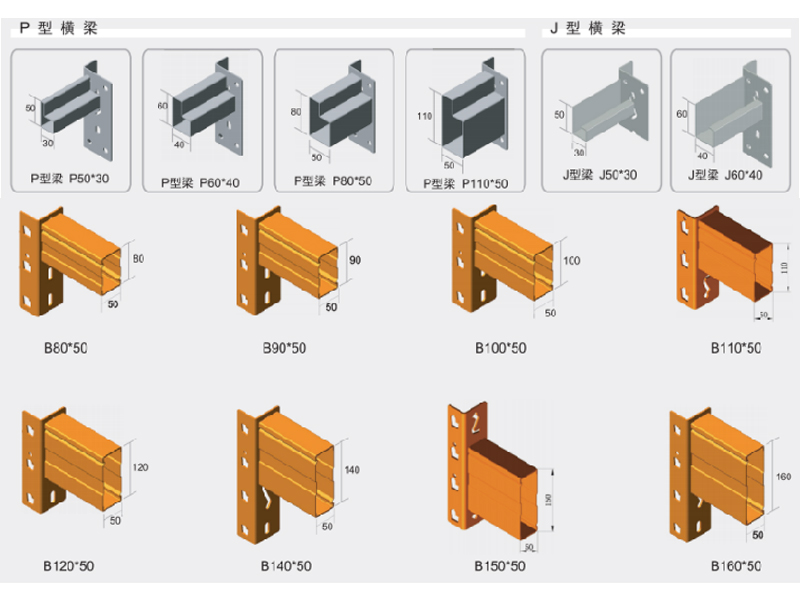

55-type uprights:

Side guardrails: φ32×1.5 mm round tube tie rods

Beam-side guardrails: φ32×1.5 mm round tube cross-beams

80-type uprights:

Side guardrails: 50×30×1.5 mm rectangular tube braces

Beam-side guardrails: 50×30×1.5 mm or 60×40×1.5 mm rectangular tube cross-beams

Kickboard size: H100×δ1.5 mm

Wanting to know more about the design details? Contact our technical team to get a custom solution.

Applications

Mezzanine racking is ideal for warehouses with higher ceilings, lighter goods, manual picking, and the storage of multiple varieties in small batches. It makes full use of vertical space while allowing convenient access and management of goods.

Mezzanine racks are commonly used for storing small packaged items such as hardware tools, electronic components, and mechanical spare parts.

The mezzanine racking system is widely applied in industries including power, machinery, automotive, and electronics.

Why Choose HEGERLS Mezzanine Racking

Nearly 30 years of expertise in warehouse racking design and manufacturing.

Advanced production facilities ensuring consistent quality and durability.

Tailor-made solutions for ambient, constant-temperature, and cold storage facilities.

End-to-end service: design, manufacturing, installation, and after-sales support.

Why Mezzanine Racking Is a Smart Investment

Installing a mezzanine racking system is far more cost-effective than relocating or expanding your warehouse. It maximizes ROI by providing additional storage or workspace in a fraction of the time and cost of construction.

Ready to unlock the hidden potential of your warehouse?

Contact us today for a free consultation and customized mezzanine racking design that fits your needs perfectly.