Cold Storage Racking System

- HEGERLS

- Xinhe Industrial Park, Hebei, China

Main Types of Cold Storage Racking

High-density system allowing forklifts to drive directly into the rack structure for pallet storage. Ideal for low-frequency operations and full-pallet in/out handling. It achieves a space utilization rate of 60%–75%, suitable for long-term storage of bulk goods such as meat and dairy products.

Uses an automated shuttle to transport pallets within the rack lanes, minimizing forklift entry into the cold room and improving energy efficiency. Adopts a "goods-to-person" operation mode, supporting both FIFO and LIFO strategies. Storage density is increased by over 30% compared with traditional racking systems. Ideal for storing single-category, large-batch goods such as food and pharmaceuticals.

Mounted on rails to create or close aisles as needed, increasing capacity by over 80% compared to fixed racks.

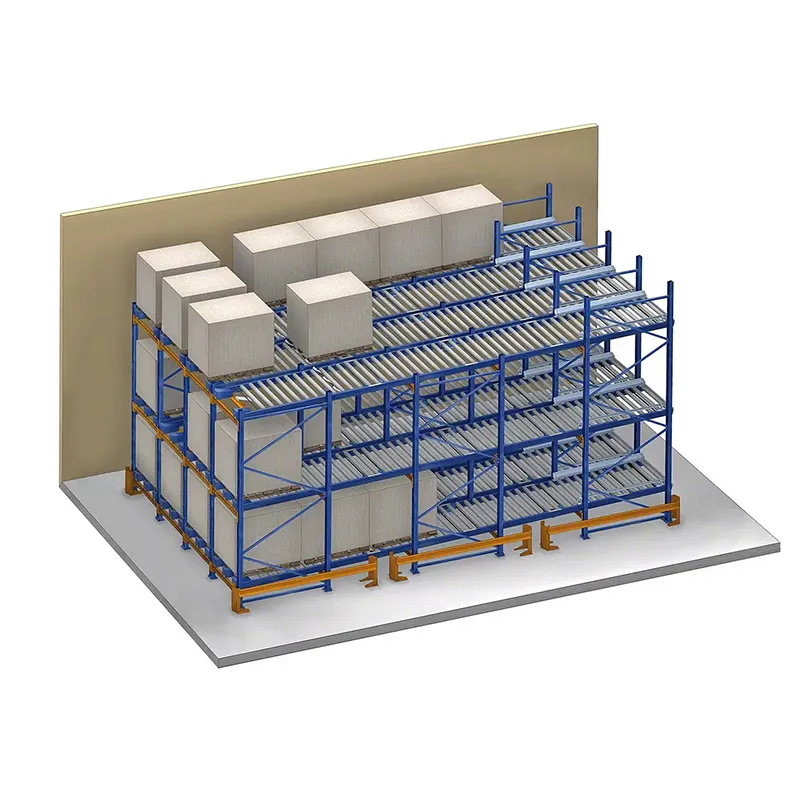

A high-density storage system that uses sloped roller or wheel tracks to allow goods to move from the loading end to the picking end by gravity, enabling a First-In-First-Out (FIFO) operation. Space utilization can reach 60%–70%. Ideal for industries such as food & beverages, dairy products, cold storage, pharmaceuticals, etc

Standard pallet racking offering easy access to every pallet, suitable for mixed SKU storage.

Key Features of Low-Temperature Warehouse Solutions

Low-Temperature Resistant: Built with special steel and anti-corrosion coatings to withstand freezing conditions without deformation.

High-Density Storage: Maximizes warehouse capacity, reducing cooling space and energy consumption.

Corrosion Protection: Hot-dip galvanizing or epoxy powder coating for long-term durability in humid and icy environments.

Automation Compatible: Can be integrated with shuttle cars, stacker cranes, and other equipment to enable semi-automated storage and retrieval, significantly reducing manual operation time.

Custom Design: Tailored to your warehouse size, storage capacity, and picking method.

Applications

Frozen food storage

Meat and seafood processing plants

Pharmaceutical cold storage

Dairy products and beverage warehouses

Cold chain distribution centers

How to Choose the Right Cold Storage Racking Manufacturer

Choosing the right manufacturer is critical for long-term performance, safety, and cost savings in cold storage facilities.

Experience in Cold Storage Projects

Look for manufacturers with proven cold storage project experience, able to handle -25℃ environments and provide case studies.

Material Quality & Coating Technology

Ensure the use of high-strength steel, hot-dip galvanizing or epoxy powder coating, and moisture-resistant components.

Customized Design Capabilities

The supplier should offer tailored rack sizes, load capacities, and layouts for maximum storage density and compatibility with cold store forklifts or shuttle systems.

Compliance with Safety Standards

Check for compliance with FEM, RMI, and ISO standards to ensure safety and reliability.

Installation & After-Sales Support

Choose a supplier with professional cold storage installation teams, maintenance services, and quick spare parts supply.

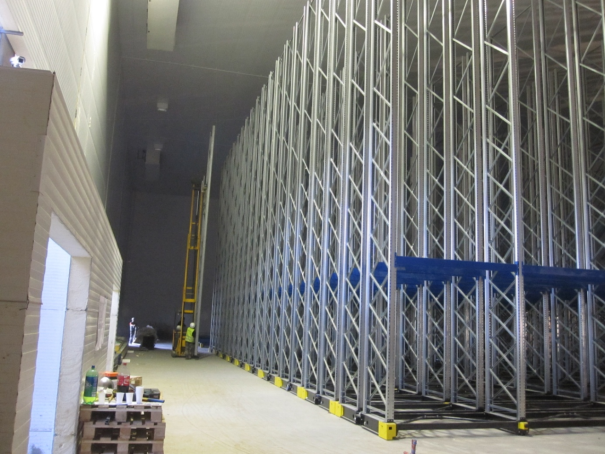

HEGERLS Drive-in Racking Cold Storage Project in Chile

Why Choose HEGERLS?

With nearly 30 years of global expertise in planning and designing logistics parks, HEGERLS team delivers customized, one-stop solutions for ambient, temperature-controlled, and cold storage facilities across diverse industries.

Leveraging the strong capabilities of our production and R&D bases, we design and manufacture high-quality warehouse racking systems and integrated storage equipment that offer outstanding performance, durability, and value.

Partner with HEGERLS today for tailored warehouse solutions that elevate your operations.

HEGERLS Production Base

HEGERLS Production Base HEGERLS Headquarters

HEGERLS Headquarters HEGERLS R&D Center

HEGERLS R&D Center