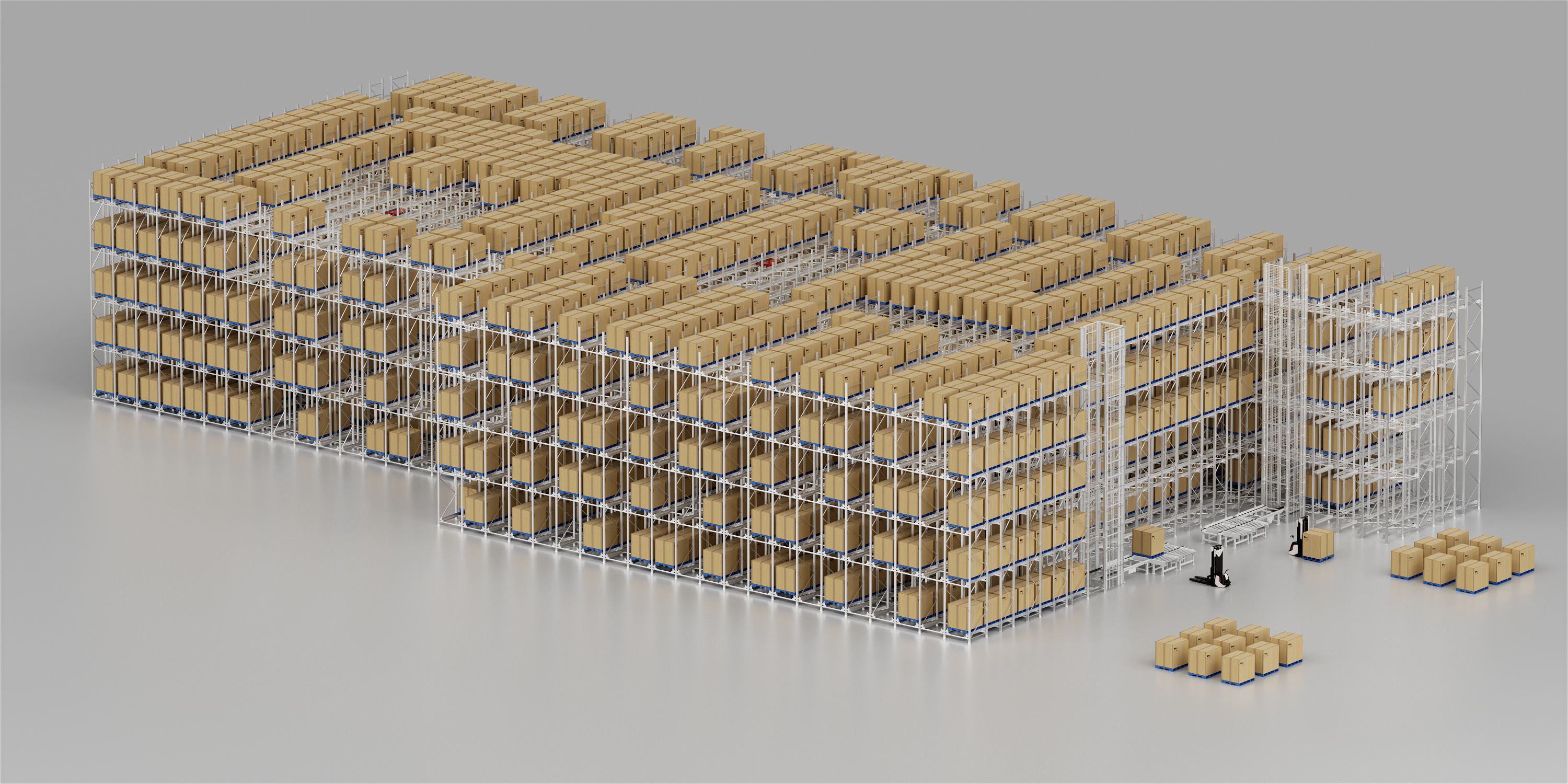

Pallet Shuttle System

- HEGERLS

- Xinhe Industrial Park, Hebei, China

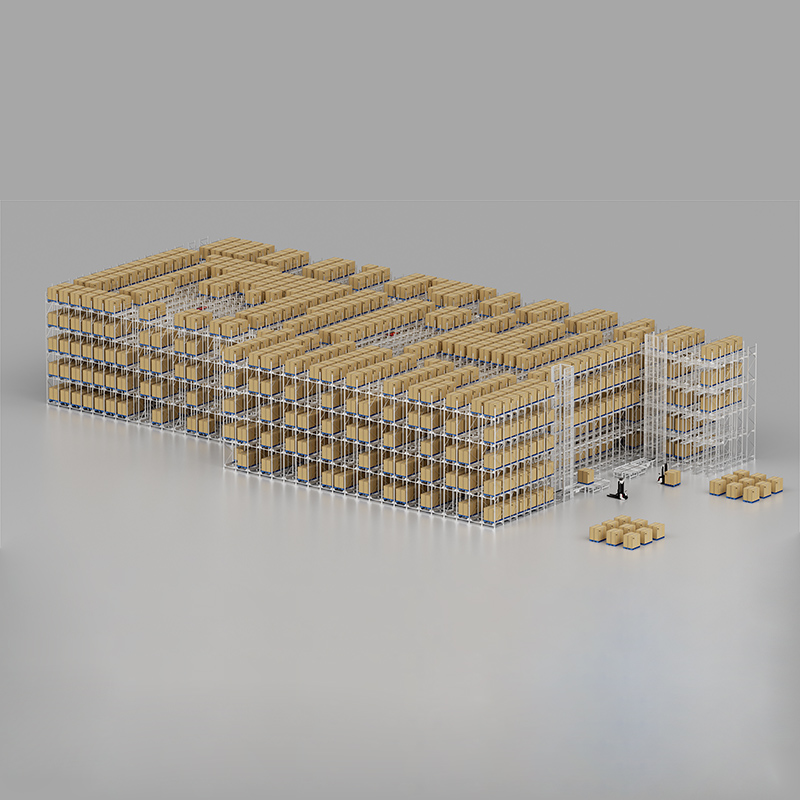

Product Introduction

The shuttle pallet rack system is a semi-automated storage system composed of forklifts, shuttles, racks, etc. This highly efficient storage method aims to improve the utilization rate of warehouse space and bring new storage options to customers!

Operation Process

Placing the Shuttle

The forklift places the WAP-1 shuttle at the entrance of the designated rack lane.

The shuttle operates independently on rails beneath the pallets without continuous forklift involvement.

Goods Storage (Inbound)

The forklift transports pallets to the front position of the lane.

The shuttle automatically carries the pallets deep into the lane for safe storage.

Goods Retrieval (Outbound)

The shuttle moves pallets from inside the lane to the front position.

The forklift collects pallets at the front end, reducing travel distance and improving speed.

Shuttle Relocation

A forklift can move the WAP-1 shuttle between different lanes and storage levels.

One shuttle can serve multiple lanes, with the required number depending on lane depth, pallet volume, order batches, and outbound frequency.

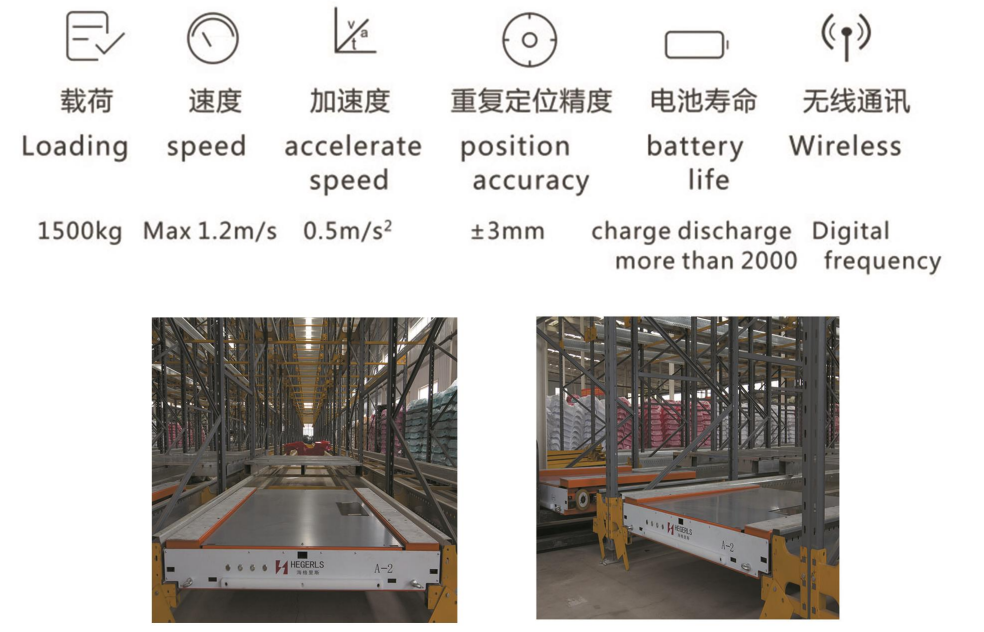

Product Parameter

Load capacity: 1000 - 1500 kg

Operating speed: 0.7 - 0.9 meters per second when unloaded

Operating speed: 0.6 - 0.8 meters per second when fully loaded

Power unit: Lithium battery

Rated voltage: 24V

Battery life: The normal usage time is more than 8 hours

Sensing range: The sensing range of the remote control is 50 meters (theoretically 100 meters, and it can reach up to 200 meters, which depends on the on-site environment)

Optimal lane depth: It should be designed according to the inventory ratio, and theoretically controlled at 50 pallet positions.

Composite operation per hour: 40 pallets per hour (on average), and the high-efficiency operation is 45 pallets per hour.

Product Feature And Application

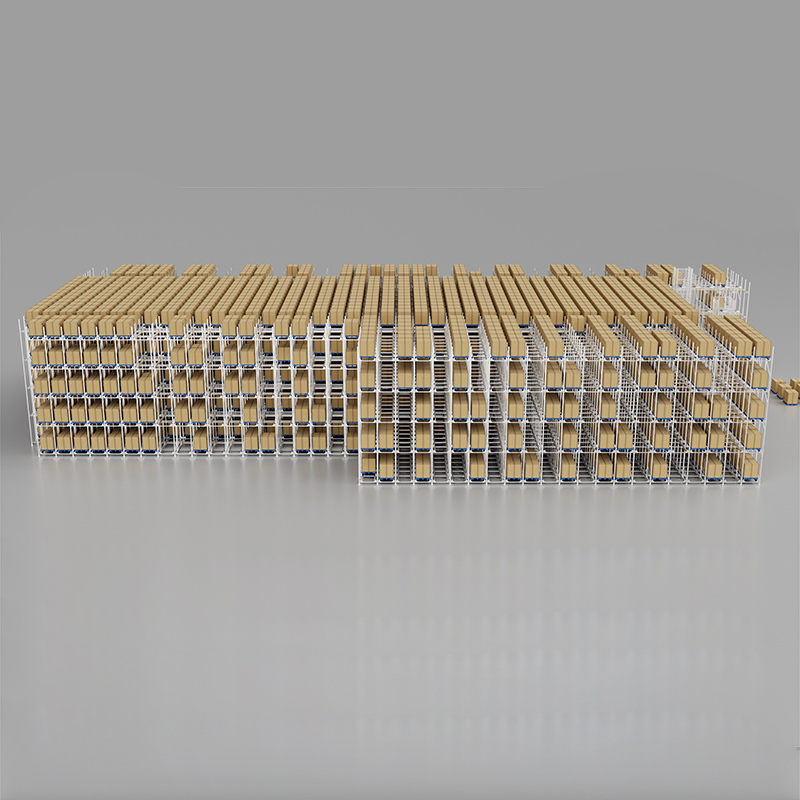

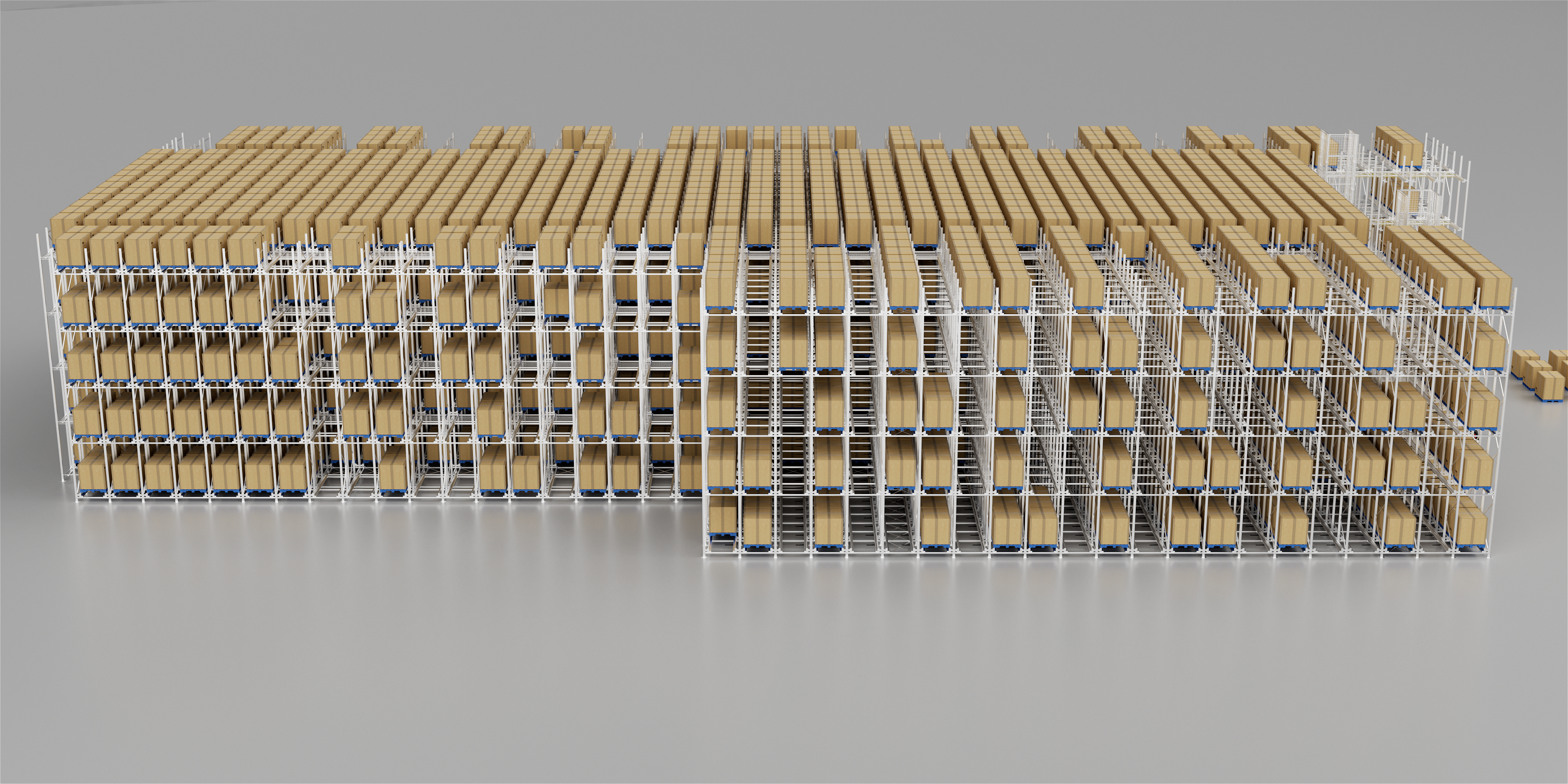

The solution for the warehouse is composed of shuttle pallet racks with a certain number of rack groups and a system for pallet warehousing, transportation, and storage by shuttles. The space utilization rate is over 80%!

Features of the shuttle rack:

High-density storage, resulting in a high utilization rate of the warehouse.

High work efficiency, greatly reducing the operation waiting time.

Flexible operation mode. The goods can be stored and retrieved in either a first-in-first-out or a first-in-last-out manner.

High safety factor, reducing the collision between the rack and the forklift and improving the safety production rate.

Flexible & Scalable: One shuttle can serve multiple lanes; additional shuttles can be added as demand grows.

Fast & Accurate: Remote-controlled shuttle ensures precise pallet positioning and retrieval.

Relatively low requirements for lighting.

The applicable scope of the shuttle rack system

Large quantity and few varieties: Industries with large batch quantities of single product types and relatively simple item categories, such as food, beverages, chemicals, tobacco, etc.

Cold storage operations: Reducing the time of low-temperature operations, improving work efficiency and operational safety.

Term management: Warehouses with strict requirements for item batches and in need of first-in-first-out operation management.

Increasing storage capacity: Warehouses with limited storage space that require maximizing the use of space.

In Thailand jinming group warehouse, HEGERLS brand radio shutle storage equipments are completely assembled and successfuly tested.

Prodection Details

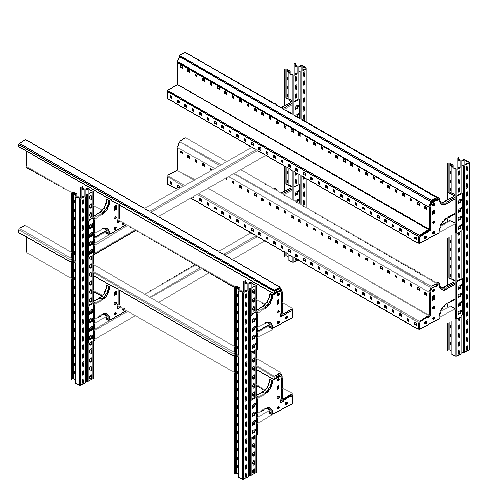

Selection of shuttle car guide rails

The guide rail has a special-shaped cross-section. Its upper surface comes into contact with the pallet, the lower surface contacts with the traveling wheels of the shuttle car, and the side surface contacts with the guide wheels of the shuttle car. In order to enable the shuttle car to move smoothly on the track within the lane, a high level of straightness is required. Additionally, the guide rail needs to have a certain bending resistance. The guide rail is commonly connected to the corbel by round-head bolts (carriage bolts).

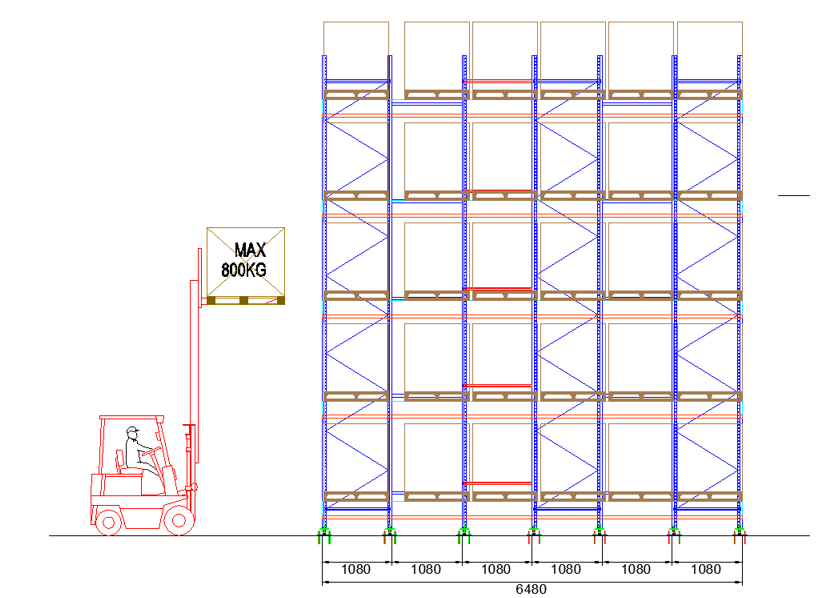

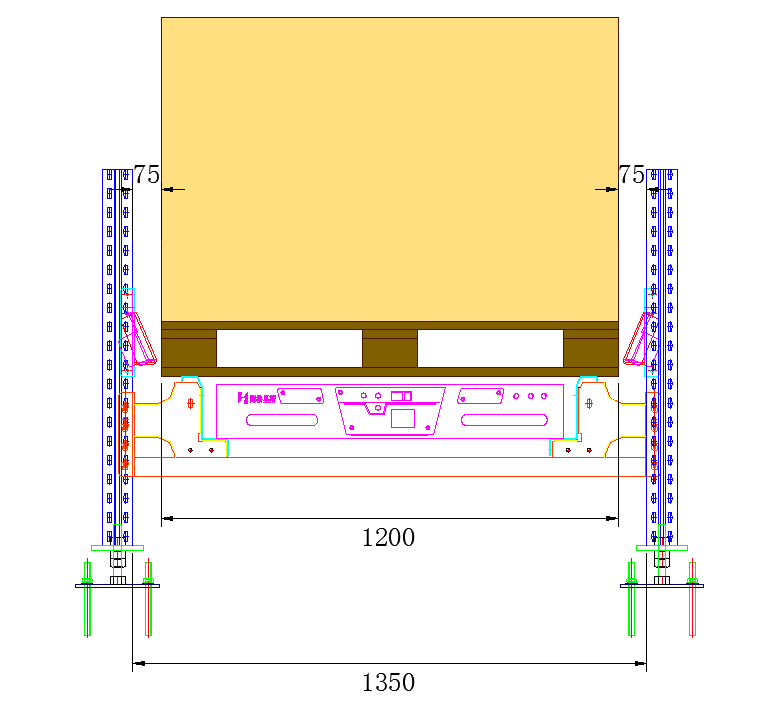

Requirements for the depth of the upright frame, the width of the passageway, and the size of the pallet

For the commonly used shuttle cars, the most suitable pallet size is 1200W * 1000D. Considering relevant factors such as the forklift and pallet size, for the upright frame of the first unit, the depth of the upright frame should be the pallet depth plus 300mm, and the width of the passageway is generally 1350 - 1400CE.

In addition, to ensure the overall stability of the rack, horizontal cross tie rods (horizontal and diagonal bracing tie rods) need to be installed between some of the supporting beams.

Why Choose HEGERLS Pallet Shuttle System?

Almost 30 Years of Expertise in intelligent warehousing and automation systems.

Customized Solutions tailored to your specific storage and operational needs.

Proven Global Projects in logistics, manufacturing, food & beverage, and e-commerce.

Quality Assurance with international certifications and advanced production facilities.

Choose our Pallet Shuttle System to achieve higher density, safer operations, and smarter warehouse management.Get a Quote Now!