Project Background

A mid-sized apparel manufacturer faced increasing pressure as SKU diversity, seasonal fluctuations, and rapid order cycles continued to rise.

Although the warehouse had a clear height of 7.2 meters, only the ground floor was utilized. This resulted in:

Low space utilization

Mixed and disorganized inventory

Slow picking and replenishment speed

Difficulty handling e-commerce order peaks

To address these challenges, the company decided to implement a HEGERLS steel platform system, transforming the warehouse into a multi-level, high-efficiency operation.

Solution Overview

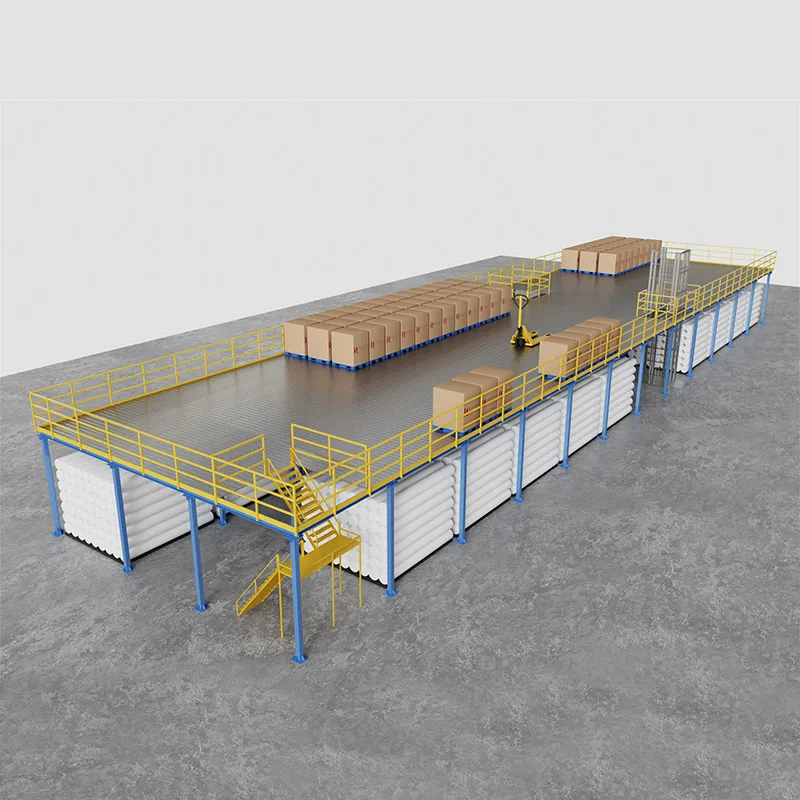

HEGERLS provided a custom-designed 557 m² steel platform, built to support apparel storage characteristics and tailored to the customer’s operations. The solution included:

Steel platform structure, maximizing vertical space

Load capacity designed for apparel cartons and hanging items

Integrated staircases, safety railings, and pallet gates

Optimized layout for fast picking and streamlined replenishment paths

Durable powder-coated finish to resist wear and corrosion

Key Features

High Space Utilization: The steel platform created an additional operational level, effectively doubling usable storage area without expanding warehouse footprint.

Improved Picking Efficiency: Clear zoning separated fast-moving, slow-moving, and seasonal items, allowing workers to quickly locate and pick products.

Strong Structural Stability: The platform meets industrial load-bearing requirements for apparel logistics, supporting both carton storage and light shelving.

Flexible Layout for Future Expansion: The modular design allows future extensions and reconfiguration as SKU quantity or business volume grows.

Implementation Highlights

Total Area: 557 m²

Platform Type: Steel platform structure

Application: Apparel cartons, accessories, and seasonal stock

Project Duration: From design to installation, completed in approximately 25 days

Customer Benefits

100% Increase in Storage Capacity: By using vertical space effectively, the storage density doubled.

35–50% Faster Picking: Optimized walking paths and clearer inventory organization significantly improved operational speed.

Reduced Labor Costs: With a structured layout and improved visibility, workers handle orders more efficiently.

Higher Safety Standards: Enhanced railings, anti-slip flooring, and pallet gates ensured safer operations, especially during peak order seasons.

Conclusion

The HEGERLS 557 m² steel platform provided the apparel manufacturer with a scalable, cost-effective, and durable storage upgrade.

By transforming vertical space into productive operational zones, the company achieved higher storage density, reduced picking time, and improved overall warehouse efficiency—creating a strong foundation for future business growth.

Ready to maximize your warehouse space? Contact HEGERLS today for a free consultation and get a tailored steel platform design for your facility.