As global warehousing undergoes rapid digital transformation, logistics operators face constant pressure to increase storage density, accelerate order fulfillment, and reduce labor dependency. In this evolving landscape, the four-way pallet shuttle has emerged as one of the most disruptive technologies for modern automated warehouses. Responding to global demand, HEGERLS today announced a major upgrade to its four-way pallet shuttle system—featuring stronger performance, smarter scheduling, and seamless integration with ASRS, WMS, and WCS platforms.

HEGERLS new-generation system is engineered for warehouses that seek maximum throughput with minimum footprint. Designed for manufacturing, e-commerce, cold storage, third-party logistics, and FMCG sectors, the system represents a decisive shift toward fully autonomous pallet handling inside high-density racking structures.

What Is a Four-Way Pallet Shuttle?

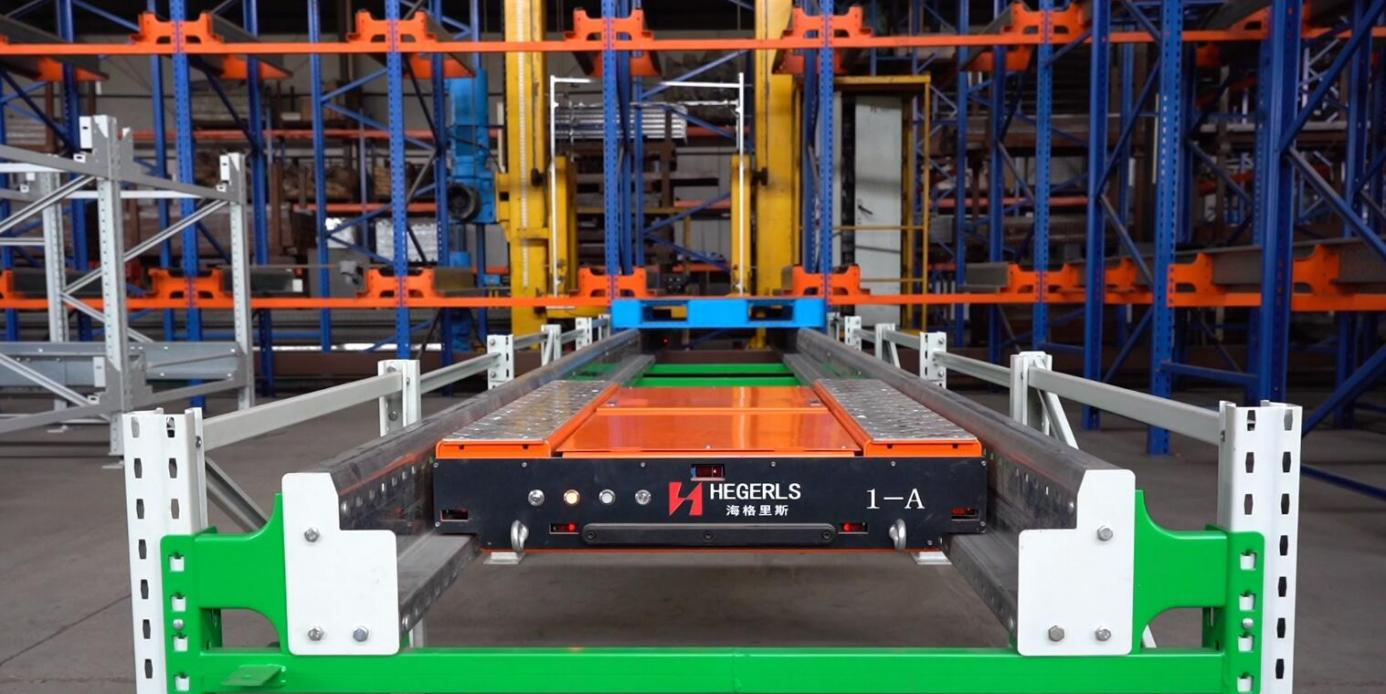

A four-way pallet shuttle is an intelligent robotic carrier capable of moving pallets forward, backward, left, and right inside a multi-layer racking system. Unlike traditional shuttles that operate only in one direction, the four-way design allows the robot to freely navigate complex rack networks, transfer between aisles, and access storage channels with exceptional flexibility.

This multi-directional ability enables:

High-density storage with reduced aisle requirements

Dynamic traffic routing based on real-time conditions

Greater utilization of cubic space

Rapid SKU access for both inbound and outbound tasks

In a fully automated setup, multiple shuttles operate simultaneously—coordinated by software to create a self-organizing warehouse ecosystem.

Market Drivers Behind the Surge in Four-Way Shuttle Adoption

HEGERLS identifies three major industry trends fueling explosive growth of four-way pallet shuttle solutions:

Rising Labor Costs and Skill Shortages

Global warehousing continues to struggle with forklift operators shortages. Businesses are increasingly turning to automation to maintain productivity and safety.

Demand for Cold-Chain Efficiency

Cold storage operators prioritize automation due to energy costs and labor constraints. Four-way shuttles significantly reduce human presence in low-temperature zones.

High-Density Urban Warehousing

With real estate prices soaring, companies seek to maximize vertical and cubic storage. Four-way shuttles support ultra-high-density layouts previously impossible with forklifts.

These market shifts have positioned the four-way pallet shuttle as a core technology for the next generation of smart warehouses.

Key Features of the HEGERLS Four-Way Pallet Shuttle

Multi-Directional Movement for Full Warehouse Coverage

The shuttle’s four-directional mobility eliminates the need for multiple forklifts and reduces aisle space. It can autonomously switch aisles, bypass obstacles, and select optimal routes.

AI Scheduling and Traffic Control

Powered by the HEGERLS WCS algorithm, the system analyzes order waves, real-time pallet locations, and shuttle availability to achieve:

Optimal task allocation

Collision-free traffic

Continuous high throughput

Balanced workload among shuttles

High-Speed Handling and Precise Positioning

With acceleration control and ±3 mm positioning accuracy, the shuttle ensures stable operations even under high load conditions, supporting both FIFO and LIFO strategies.

Seamless Integration with WMS & ERP

The shuttle interacts directly with the warehouse management software, enabling:

Digital inventory

Automated replenishment

Batch picking

Real-time pallet traceability

Battery Performance and Fast Charging

HEGERLS latest lithium battery technology offers:

Over 2000 charge cycles

Fast charging in minutes

Intelligent power-swap notification

Safety-first Architecture

Features include obstacle detection, overload protection, emergency braking, and anti-collision algorithms to ensure reliable 24/7 operation.

Business Impact — How Four-Way Shuttles Transform Warehouses

Storage Density ↑ 40–80%

Eliminating conventional aisles allows warehouses to dramatically expand capacity.

Throughput ↑ 2–3×

With multiple shuttles running simultaneously, inbound/outbound cycles accelerate significantly.

Labor Costs ↓ 50–70%

Most manual forklift operations are replaced with autonomous handling.

Zero-Wait Operations

Shuttles work continuously without shift changes or fatigue.

Lower Operating Costs

Reduced lighting, heating, and equipment damage lead to substantial savings.

Industries Where Four-Way Shuttles Deliver Maximum Value

Cold Storage & Food Distribution: High-density storage and minimized human presence dramatically reduce energy consumption.

E-Commerce Fulfillment Centers: Supports rapid order picking, SKU diversification, and high seasonal throughput.

Manufacturing Plants: Provides consistent pallet movement between production lines and storage zones.

3PL Logistics Providers: Enables flexible storage rental, faster inventory turnover, and scalable operations.

Pharmaceutical Warehousing: Ensures traceability, temperature control, and batch management.

Comparing Four-Way Shuttles to Other Automated Storage Systems

Four-Way Shuttle vs. Two-Way Shuttle

Four-way offers multi-direction navigation

Supports higher-density layouts

Enables aisle switching without auxiliary equipment

Four-Way Shuttle vs. Traditional ASRS

More flexible and scalable

Lower maintenance requirements

Faster installation and lower upfront cost

Four-Way Shuttle vs. AGVs/AMRs

Operates fully inside racking

No need for large travel aisles

Ideal for pallet loads rather than cartons

The HEGERLS Innovation Roadmap

HEGERLS confirms upcoming R&D advancements including:

5G-enabled shuttle communication

Digital twins for predictive maintenance

Machine learning for demand forecasting

Adaptive energy management system

These enhancements aim to bring decision-making autonomy deeper into the warehouse floor.

Real Customer Case – From Bottleneck to High-Speed Automation

A leading distributor in Southeast Asia upgraded its manual pallet warehouse to the HEGERLS four-way shuttle system. Results within 90 days:

Storage volume increased by 65%

Outbound picking speed improved by 2.4×

Labor costs reduced by 58%

Inventory accuracy reached 99.8%

System availability maintained at 99.5% uptime

This case demonstrates how the technology can transform operational models across industries.

The Future of High-Density Automation

Four-way pallet shuttle systems are no longer supplemental tools—they are becoming the core engine of intelligent warehousing. As global enterprises accelerate automation, these systems will define future standards for capacity, resilience, and data-driven decision-making.

HEGERLS continues to drive this evolution with innovation, engineering reliability, and global implementation experience.

Conclusion

The rise of the four-way pallet shuttle marks a new chapter in warehouse automation. With its unmatched flexibility, density optimization, and intelligent coordination, the technology is reshaping logistics infrastructures worldwide. As HEGERLS advances shuttle intelligence and hybrid automation ecosystems, businesses will gain the speed, scalability, and resilience required to compete in tomorrow’s logistics landscape.

About HEGERLS

HEGERLS specializes in smart storage and automation solutions including four-way pallet shuttles, radio shuttle systems, stacker crane AS/RS, AGVs/AMRs, mezzanine systems, and intelligent warehouse software (CC-WMS & YUNTU-WCS). With decades of engineering experience, HEGERLS supports global clients with system design, manufacturing, and end-to-end implementation.

Ready to upgrade your warehouse with HEGERLS four-way shuttle systems? Contact our team today and discover how we can design your next-generation automated warehouse.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955