[Hebei, China — October 2025] — According to a recent press release, the Four-Way Shuttle Racks market is projected to grow from USD 1,295.2 million in 2025 to USD 2,341.5 million by 2035, at a compound annual growth rate (CAGR) of about 6.1%.

This projected growth reinforces the increasing demand for high-density warehouse automation solutions — particularly those that can meet demands for space efficiency, throughput, labor savings, and modern digital integration. HEGERLS, with its strong portfolio of shuttle systems, stacker cranes, rack-supported structure offerings, mobile racks, and in-house software like CC-WMS and YUNTU-WCS, is well placed to capitalize on this expanding market.

Key Findings from the Four-Way Shuttle Rack Report

Here are the main data points and trends from the report:

Metric | Value / Trend |

Market Value in 2025 | USD 1,295.2 million |

Forecast Value in 2035 | USD 2,341.5 million |

Forecast CAGR (2025–2035) | ~ 6.1% |

Growth Phases | First half (2025-2030) adds ~ USD 446.3 million, second half (2030-2035) adds ~ USD 600 million, i.e. about 57.3% of growth expected in the later phase. |

Leading Automation Level | Fully-Automatic systems are expected to dominate (~62% market share in 2025) of this shuttle rack segment. |

Top Application Segment | Third-Party Logistics (3PL) is the largest application (~34% share in 2025) because 3PLs need to handle multi-client inventory, diverse SKUs, and high throughput. |

Key Regions | Asia-Pacific, North America, and Europe are primary growth regions. Asia-Pacific expected to lead. |

Driving Forces Behind the Growth

Demand for Space Efficiency

Urban land scarcity and rising warehouse rents drive adoption of shuttle-based racking systems that utilize both horizontal and vertical space efficiently.

Automation and Labor Optimization

Fully automated shuttle systems already hold over 60% market share. Labor shortages and high wages in logistics hubs further fuel automation upgrades.

E-Commerce and 3PL Expansion

Third-party logistics (3PL) providers—handling multi-client, multi-SKU storage—represent 34% of market share. They increasingly turn to shuttle solutions for dynamic storage allocation.

Cold-Chain and Temperature-Controlled Storage

The refrigerated warehousing segment is booming, with special requirements for shuttle reliability at –22 °C. HEGERLS’ cold-environment four-way shuttle systems meet these challenges with sealed drives and anti-frost designs.

Implications & Strategic Position for HEGERLS

Given these market trends, here are how HEGERLS can align to gain maximum advantage:

Emphasizing Fully-Automatic Solutions

As the report confirms, fully automatic four-way shuttle systems represent a large and growing share. HEGERLS should focus R&D and product promotions on fully automated shuttle racks — faster shuttles, robust path planning, minimal labor dependency.

Targeting 3PL & E-Commerce Verticals

3PL providers are especially likely to invest in four-way shuttle racks. HEGERLS can tailor offerings (both hardware and software) specifically for these customers: flexible SKUs, high throughput, frequent changeovers, multi-client billing & inventory separation.

Asia-Pacific Prioritization

Given the rapid growth projected in Asia Pacific, HEGERLS should strengthen presence there—local partnerships, localized manufacturing, faster delivery, service support, possibly tailor products for local regulations and labor cost constraints.

Simplifying Retrofit & Integration

One major barrier noted is integrating new shuttle rack systems with existing warehouses and WMS infrastructure. HEGERLS’ CC-WMS / YUNTU-WCS can be positioned as plug-in / integration layers to reduce retrofit disruption. Also, shuttle rack designs that can be modular or semi-modular help.

Managing Capital & Total Cost of Ownership (TCO)

Though initial costs are high, the long-term ROI (space saved, labor reduction, throughput improvement) is compelling. HEGERLS should provide ROI calculators, demonstration of payback periods, possibly financing or phased deployment options.

HEGERLS Product & Strategy Mapping

Here’s how HEGERLS’ existing and potential offerings map well to the four-way shuttle rack market:

HEGERLS Product/System | How It Matches Four-Way Shuttle Rack Demand | Key Features / Enhancements |

Four-Way Shuttle Systems (Hardware) | Direct fit: four-way shuttle racks are essentially this system. HEGERLS with strong engineering & supply chain can compete. | Enhance speed, durability; ensure cold chain compatibility; improve shuttle path algorithms; support different load capacities (1-1.5t etc.) as report suggests. |

CC-WMS (Warehouse Management System) | Need for WMS that integrates with four-way shuttle racks, handles slotting, inventory, performance tracking. | Expand features: predictive analytics, real-time monitoring, integration with sensor data; UI dashboards for throughput, energy, maintenance. |

(Warehouse Control System) | Dynamic command layer between hardware and WMS, manages shuttle traffic, collision avoidance, priority tasks. | High reliability, low latency; modular control for retrofit; robust error/fallback handling. |

In cases where shuttle racks are too expensive or not suitable, these offer complementary high-density storage; possibly hybrid layouts. | Combine shuttle with drive-in in portions; design rack-supported warehouses to reduce building cost. | |

For flexible storage when demand fluctuates, or when a warehouse must adapt to changing SKU mix. | Use mobile racks for slower-moving SKUs, seasonal goods; reserve shuttle usage for high-velocity SKUs. |

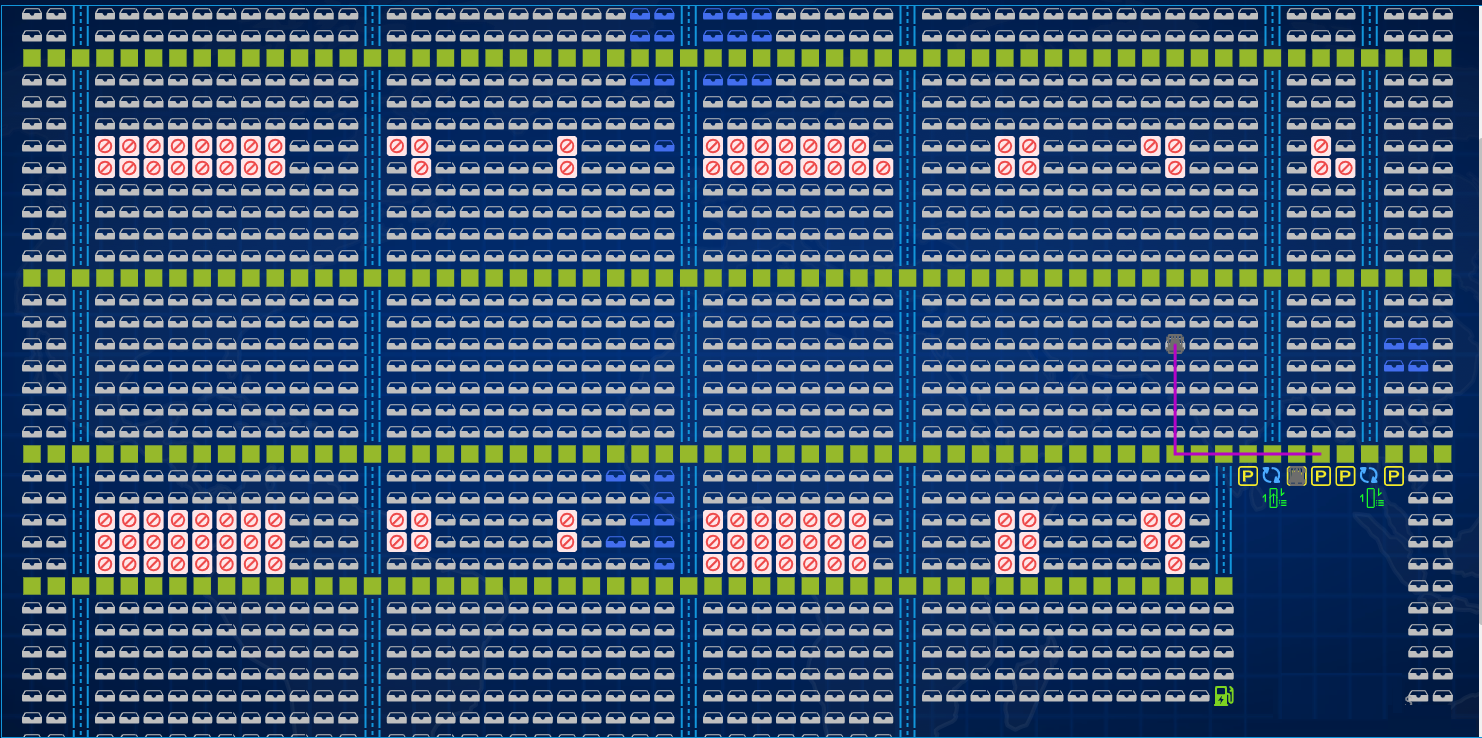

Product Spotlight: HEGERLS Four-Way Shuttle System

HEGERLS offers a mature, performance-proven Four-Way Shuttle System as part of its automation product portfolio. Below is an integrated presentation combining general market trends and product details.

Key Features & Technical Highlights

Multi-directional movement: Can operate longitudinally, latitudinally, and vertically (with our Vertical Lift Module), enabling access to pallet positions in multiple directions.

High storage density: Reduces aisle space, maximizing usable warehouse footprint.

Precision control & safety: Equipped with sensors, collision avoidance, fault detection, and control logic for safe operation.

Temperature adaptability: Designed to operate reliably even in cold-chain / frozen environments (with environmental protections, sealing, and low-temperature tolerant materials).

Modular & scalable: Supports phased expansion, integration with other systems (stacker cranes, mobile racks, conveyors).

Software integration: Interfaces with higher-level systems such as CC-WMS and YUNTU-WCS for inventory management, task scheduling, and real-time monitoring.

Benefits to Clients

Space saving: By enabling access from multiple directions, four-way shuttles reduce the number of required aisles, and increases space utilization by over 20%.

Labor reduction & safety: Minimizes human intervention in dangerous or extreme temperature zones.

Speed & throughput: Fast retrieval and replenishment, optimized path planning, and boosts overall efficiency by more than 30%.

Lower operating cost: Efficient movement, reduced HVAC losses through denser layouts, reducing operating costs by 40–60%.

Flexibility: Easy to accommodate layout changes, SKU variation, and seasonal inventory shifts.

Original HEGERLS Insights

Sustainability Will Become a Core Differentiation

Future procurement decisions will not rely solely on storage density but on energy efficiency. HEGERLS integrates low-idle energy modes, optimized shuttle routes, and Eco-materials to reduce lifecycle impact.

Predictive Intelligence & Digital Twins

By combining operational data from CC-WMS and YUNTU-WCS with AI analytics, HEGERLS envisions digital twin models of entire warehouses—allowing real-time simulation of throughput, congestion, and energy use.

CC-WMS

YUNTU-WCS

Flexible Ownership Models

As capital cost remains a barrier, HEGERLS explores “Automation-as-a-Service” models—leasing or performance-based contracts that lower entry thresholds for small and mid-sized operators.

Cold-Chain Innovation

Specialized four-way shuttle variants for sub-zero environments include sealed drive systems, low-temperature lubricants, and smart charging docks that operate efficiently in –40 °C conditions.

Looking Forward

As global warehouse automation advances, four-way shuttle racks are becoming a cornerstone of next-generation storage architecture.

The market’s growth toward USD 2.34 billion by 2035 underscores how automation, intelligence, and sustainability will redefine logistics infrastructure.

HEGERLS stands ready—with advanced hardware, smart software, and a commitment to innovation—to empower enterprises worldwide to move toward smarter, greener, and more efficient warehousing.

See Our Four-Way Shuttle in Action. Whether you're upgrading an ambient warehouse or building a frozen storage facility, the HEGERLS Four-Way Shuttle System delivers density, speed, and reliability.

Contact us now to request a datasheet, request simulation layouts, or schedule a live demo.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955