December 2025 – China – HEGERLS announces the release of its advanced anti-corrosion coating technology developed specifically for rack-supported warehouses and industrial storage racking, designed to ensure long-term structural reliability in high-salinity, high-humidity, corrosive, and low-temperature environments.

In rack-supported warehouses, storage racks serve not only as storage systems but also as the primary load-bearing structure of the building. As a result, corrosion protection is a structural engineering requirement, directly affecting warehouse safety, service life, and operational stability.

Structural-Grade Anti-Corrosion Coating Process

HEGERLS applies a process-oriented, multi-stage anti-corrosion coating system engineered for load-bearing rack structures used in harsh environments.

The process includes:

l Intensive steel surface pretreatment to enhance coating adhesion

l Corrosion-resistant base layers to isolate steel from moisture and oxidation

l High-performance top coatings resistant to chemicals, humidity, and low temperatures

l Controlled coating thickness and curing for columns, beams, and connection points

This process creates a dense protective barrier that significantly slows corrosion and preserves structural integrity.

Long-Term Corrosion Protection: 10–50 Years

Based on environmental corrosion levels and project requirements, HEGERLS customizes coating systems to achieve a corrosion protection lifespan ranging from 10 to 50 years.

This long-term protection is particularly critical for:

l High-bay rack-supported warehouses

l Heavy-load industrial racking systems

l Facilities where structural replacement or shutdown is costly or impractical

By extending the service life of the rack structure, the coating process helps reduce lifecycle maintenance costs and operational risk.

Designed for Rack-Supported Warehouses and Industrial Racking

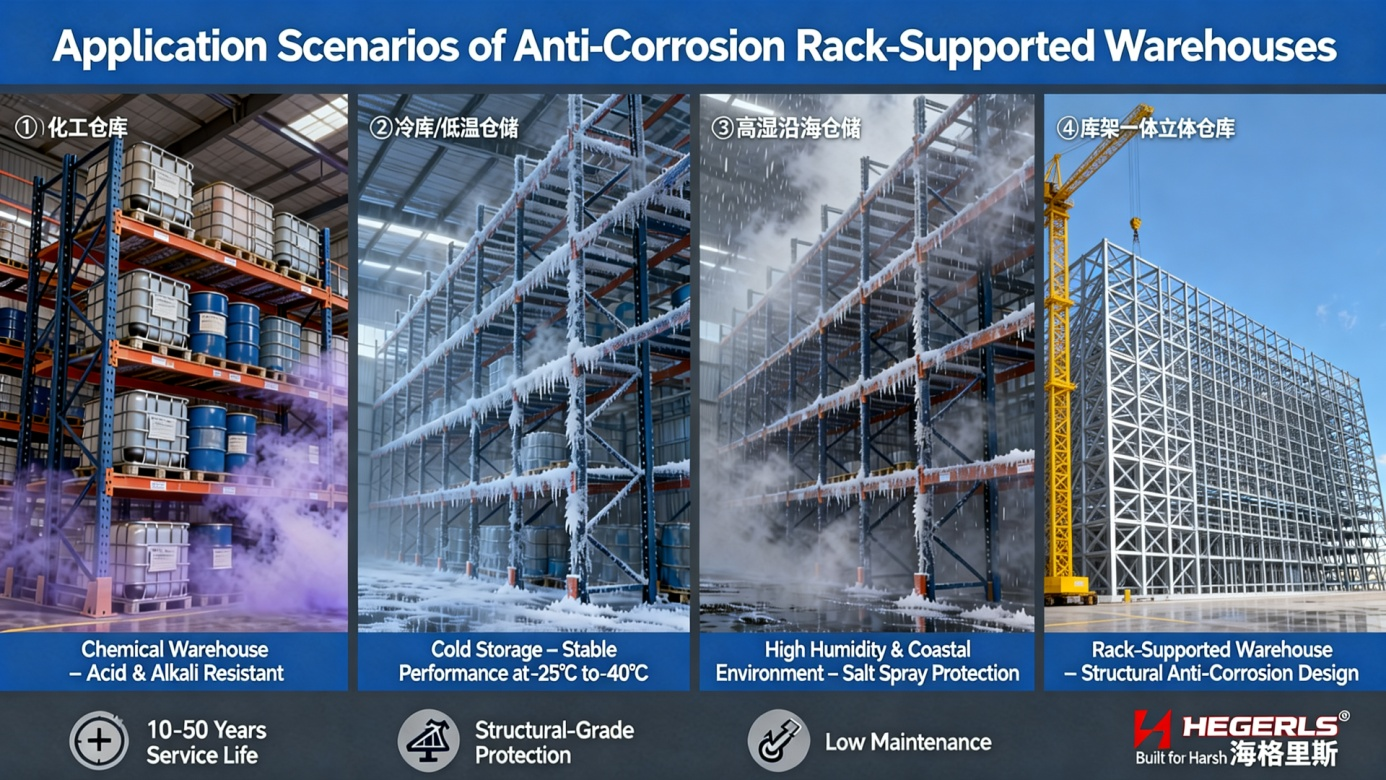

The anti-corrosion coating technology is specifically engineered for structural racking applications, including:

l Rack-supported warehouses (Clad rack) where racks act as the building framework

l Industrial pallet racking in corrosive production or storage environments

l Cold storage racking systems operating at -25°C to -40°C

l Chemical and high-humidity warehouses requiring enhanced corrosion resistance

Unlike conventional decorative coatings, HEGERLS solution focuses on structural-grade protection suitable for long-term load-bearing use.

Engineering Reliability for Harsh Environments

Through precise process control and material selection, HEGERLS ensures that coated rack structures maintain:

l Stable mechanical performance

l Strong coating adhesion without peeling or cracking

l Consistent protection at joints, bolt areas, and high-stress zones

This process-oriented approach ensures that rack-supported warehouses remain safe, reliable, and structurally sound throughout decades of operation.

About HEGERLS

HEGERLS specializes in rack-supported warehouse structures and industrial racking systems, delivering engineered solutions that combine structural strength, advanced manufacturing processes, and long-term durability for demanding storage environments.

Need Structural-Grade Corrosion Protection?

Get expert advice on anti-corrosion coating processes designed specifically for rack-supported warehouses and heavy-duty racking systems. Contact us now!

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-8724095