As warehouses and factories move toward higher levels of automation, the role of vertical material handling equipment has become increasingly critical. Traditional vertical lifts, once sufficient for basic goods movement, are now struggling to meet modern demands for speed, precision, safety, and flexibility.

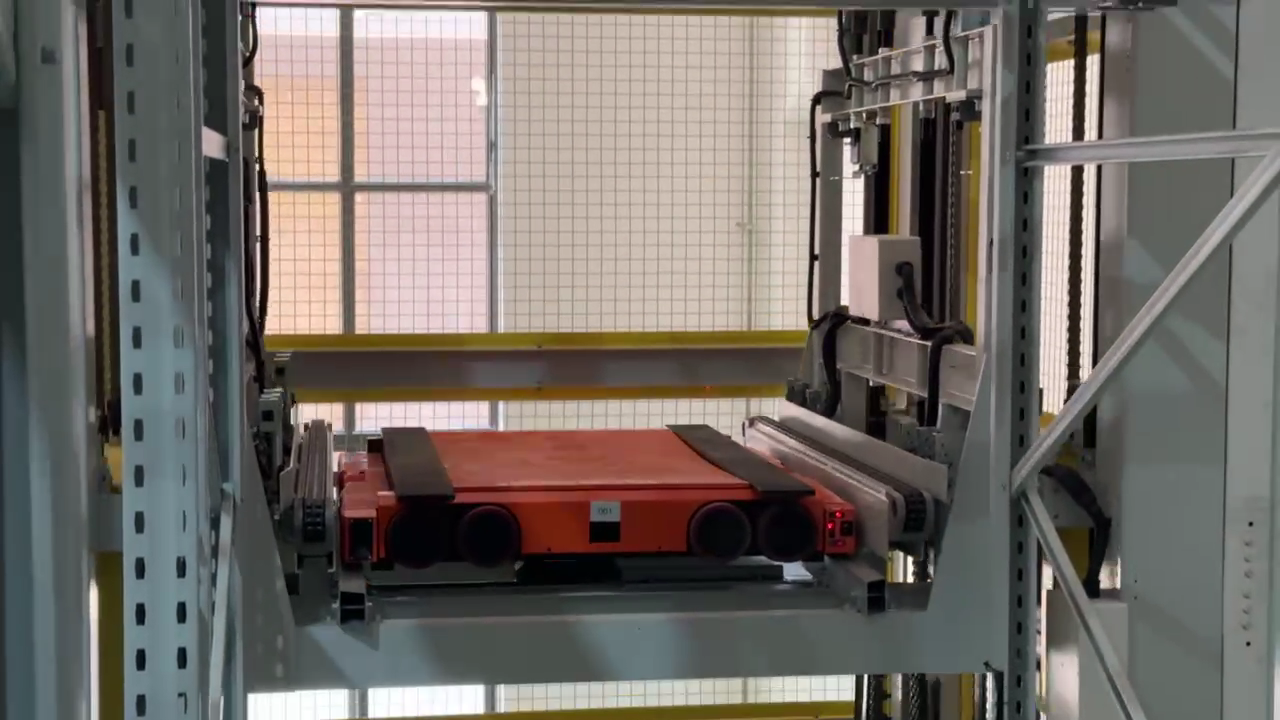

The HEGERLS Gear Rack Intelligent Vertical Lift Module (VLM) represents a new generation of vertical conveying technology. By combining intelligent control systems, high-precision gear rack transmission, elevator-grade guiding structures, and redundant safety mechanisms, HEGERLS has created a lifting solution that significantly outperforms conventional vertical lifts in efficiency, reliability, and total cost of ownership.

This article explores the key advantages of HEGERLS gear rack vertical lift modules and explains why they are becoming a core component of smart warehouses and intelligent factories worldwide.

AI-Based Intelligent Scheduling

At the heart of the HEGERLS vertical lift module lies an intelligent control system powered by advanced algorithms. Unlike traditional lifts that operate in isolation, HEGERLS lifts are integrated into an intelligent scheduling platform that enables:

l Dynamic task allocation

l Coordinated operation with shuttles, conveyors, and stacker cranes

shuttles

conveyors

stacker cranes

l Real-time path optimization

This intelligent scheduling improves material handling efficiency by more than 30%, while achieving near-100% positioning and execution accuracy—an essential requirement for high-throughput, high-density warehouses.

Fully Automated and Remote Operation

HEGERLS vertical lift modules are designed for fully automated operation, minimizing manual intervention. Through upper-level systems such as WMS and WCS, the lift can execute tasks automatically without frequent start-stop actions by operators.

In addition, the system supports:

l Touchscreen remote operation

l Visualized control interfaces (multi-language supported)

l Real-time equipment status monitoring

Compared with traditional vertical lifts that rely heavily on manual control, HEGERLS solutions significantly reduce operational complexity and human dependency.

Exceptional Precision and High Operational Efficiency

High-Precision Gear Rack Transmission

HEGERLS adopts a gear-and-rack transmission system, delivering smooth, stable, and low-noise motion. This design eliminates common issues found in chain or rope-based lifts, such as stretching, slipping, and inconsistent positioning.

Combined with four servo brake motors, the system achieves:

l Positioning accuracy ≤ 2 mm

l Stable performance during high-frequency repetitive operations

l Minimal vibration even under full load

This level of precision is especially critical for automated storage and retrieval systems (AS/RS), where millimeter-level accuracy directly impacts efficiency and safety.

Redundant Servo Brake Design

Each of the four servo motors is capable of independent braking. This redundancy provides dual assurance for both positioning accuracy and operational safety, ensuring controlled stopping even in unexpected scenarios.

High-Speed and Flexible Performance

The HEGERLS vertical lift module supports a wide speed adjustment range, such as:

l 0–60 m/min under full load

This flexibility allows the lift to adapt to different operating conditions, from high-speed order fulfillment to delicate handling of sensitive goods.

When integrated with shuttles and stacker cranes, the system enables ultra-high-density storage layouts while significantly reducing material access time.

Superior Flexibility and Application Adaptability

Multi-Load and Multi-Industry Compatibility

HEGERLS gear rack lifts are designed to handle a wide variety of loads, including:

l Pallets

l Bins and totes

l Irregular or customized goods

This adaptability makes the system suitable for diverse industries such as:

l E-commerce fulfillment

l Manufacturing and assembly plants

l Third-party logistics (3PL)

l Automotive and electronics warehouses

The modular design also allows flexible expansion as business requirements evolve.

Optimized Space Utilization

Thanks to its compact and efficient structural design, the HEGERLS vertical lift module can be installed in narrow or height-restricted spaces where traditional lifts are impractical.

Compared with conventional vertical lifts, the HEGERLS solution:

l Reduces space occupancy

l Increases overall warehouse space utilization by up to 30%

This advantage is particularly valuable in urban warehouses and facilities where floor space is limited and expensive.

Enhanced Safety and Long-Term Reliability

High-Strength Structural Design

Safety begins with structure. HEGERLS vertical lift modules are engineered with industrial-grade strength and rigidity:

l Base Structure: Rectangular steel tube welding ensures high rigidity and precise alignment.

l Columns: Manufactured from I-beam steel rather than sheet metal, delivering up to three times higher strength and stiffness.

This robust design guarantees long-term stability, even under continuous high-load operation.

Multi-Level Safety Protection

HEGERLS integrates comprehensive safety mechanisms, including:

l Dual electronic limit switches (top and bottom)

l Mechanical end stops

l Overload protection

l Limit switches and anti-slack devices

Electrical control systems and physical protection work together to prevent overtravel, collision, or mechanical failure.

Protective covers and safety fences are installed to safeguard both operators and maintenance personnel.

Elevator-Grade Guiding System

Borrowing proven concepts from elevator engineering, HEGERLS applies:

l Elevator-style guide shoe mechanisms

l T-shaped guide rails with sliding grooves for counterweights

This guiding system ensures smooth, stable, and precise vertical movement. Buffer blocks at the bottom absorb impact and further enhance operational safety.

Reduced Human Error

By shifting from manual operation to fully automated workflows, HEGERLS vertical lift modules significantly reduce the risk of accidents caused by fatigue, misoperation, or inconsistent handling—a common issue with traditional lifting equipment.

Cost Efficiency and Sustainability Benefits

Significant Labor Cost Reduction

Automation replaces repetitive manual handling tasks. A single HEGERLS vertical lift module can substitute the work of multiple operators, reducing labor costs by up to 80%.

This is especially valuable in regions facing rising labor costs or workforce shortages.

Lower Energy Consumption and Maintenance Costs

Through intelligent control and optimized operation logic, HEGERLS lifts minimize idle running and unnecessary energy consumption.

Additional cost-saving factors include:

l Modular design for faster maintenance

l Reduced mechanical wear due to gear rack transmission

l Fewer unplanned downtimes

Over the equipment lifecycle, these features translate into a lower total cost of ownership and a more sustainable operation.

Conclusion: A New Benchmark for Vertical Lifting Technology

The HEGERLS Gear Rack Intelligent Vertical Lift Module sets a new benchmark for modern warehouse automation. By combining:

l High-strength mechanical structure

l High-precision gear rack transmission

l Elevator-grade guiding technology

l Redundant safety protection

l Intelligent automation and scheduling

HEGERLS delivers a lifting solution that excels in stability, accuracy, safety, and operational efficiency.

Compared with traditional vertical lifts, HEGERLS solutions offer clear advantages in intelligent control, flexibility, safety, and long-term economics. They are particularly well-suited for industrial environments with strict requirements for precision, reliability, and scalability.

As smart factories and intelligent logistics centers continue to evolve, HEGERLS gear rack vertical lift modules will play an increasingly important role—serving as a core piece of infrastructure that enables efficient, safe, and future-ready material handling.

Looking to upgrade your warehouse vertical handling system? Contact HEGERLS to support your automation goals.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955