Transforming the Front-End of Global Manufacturing with Integrated Structural Logistics

For decades, automation companies around the world have concentrated on high-profile technologies such as AMRs, robotic arms, and unmanned production lines. Yet in countless factories, the most chaotic, costly, and overlooked battlefield is not the production line—but the front-end storage and material flow. Especially in heavy manufacturing, the storage of long materials, pallets, steel components, cold-chain goods, and bulky items remains the first bottleneck dragging down rhythm, efficiency, and safety.

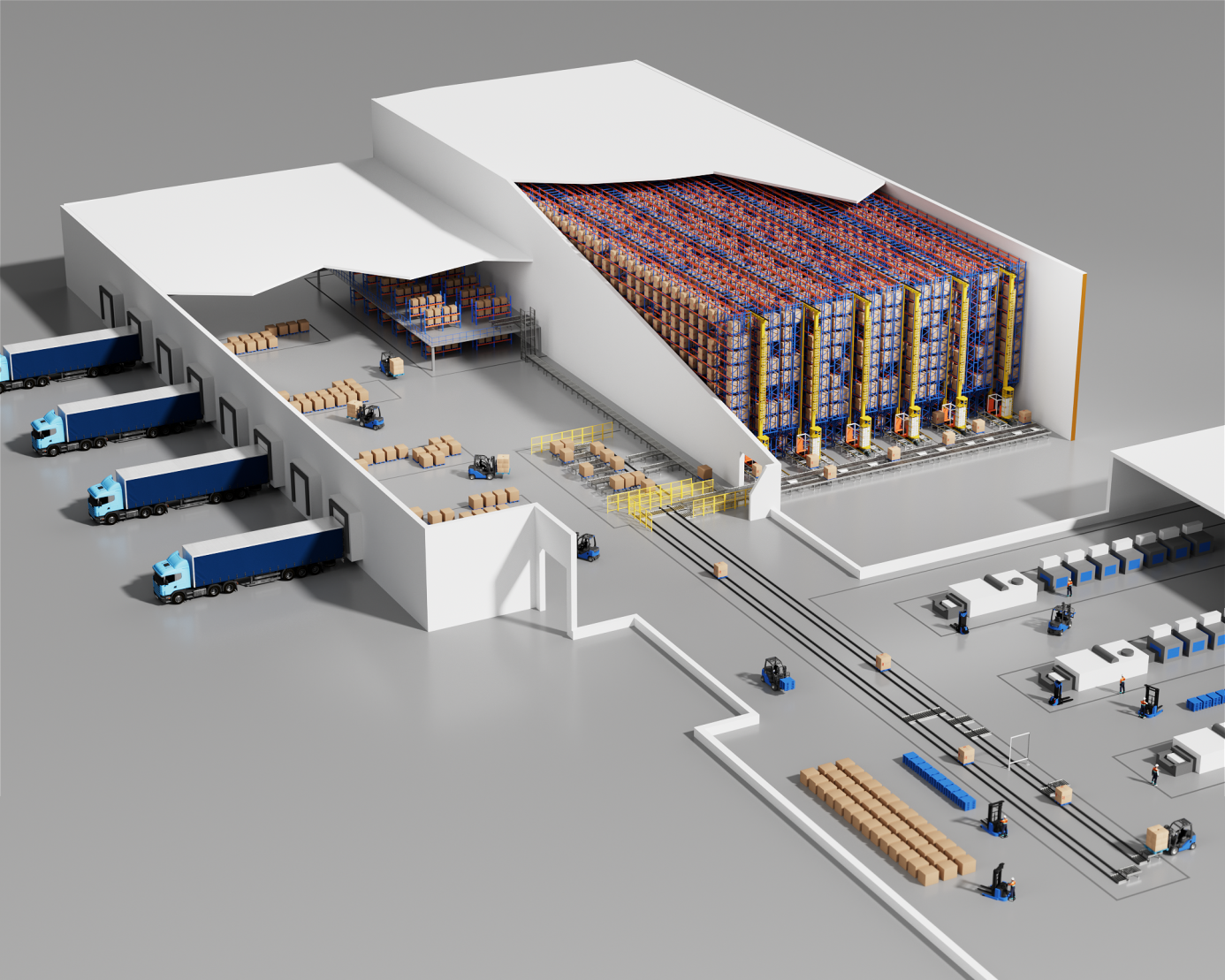

HEGERLS stepped into this “messy front-end” long before most competitors realized its strategic value. Instead of following the crowd into the saturated market of robot arms, HEGERLS positioned itself in a core but underserved domain: rack-supported warehouses, where racks are not merely storage equipment but the structural backbone of the entire building.

This forward-looking strategy, combined with deep technical integration capabilities, has turned HEGERLS from an equipment supplier into a full-scenario warehouse infrastructure provider—bridging storage, automation, data flow, and plant management into one unified system.

The Industry Problem: Front-End Warehousing Is the Hidden Weak Link

In traditional factories, warehousing often becomes an uncontrolled “grey zone.”

Pallets are stacked manually. Storage density depends on experience. Forklifts weave through narrow aisles. Raw materials go missing. Cold storage space becomes increasingly expensive. Safety hazards lurk everywhere.

Typical symptoms include:

Chaotic pallet stacking and low density, wasting 40%+ space

High labor dependence, especially in cold storage

Safety risks from forklift–worker mixed operations

Material search time consuming from minutes to hours

Production stoppage due to delayed material supply

Inventory mismatches and difficulty in traceability

All of these become critical bottlenecks as manufacturing enterprises push toward digital transformation, high throughput, and just-in-time production.

HEGERLS identified the root cause early:

“As long as the warehouse remains passive, isolated, and manually driven, factories cannot truly become intelligent.”

Thus began HEGERLS long-term commitment to rack-supported buildings + automation systems.

Why Rack-Supported Warehouses Became HEGERLS Strategic Core

A rack-supported warehouse (also called a clad-rack warehouse) is a system where the racking itself becomes the main structure of the entire building—bearing wind load, snow load, shelves, and AS/RS operations.

This approach brings a revolutionary shift in both cost and operational efficiency:

Space Becomes a Vertical Engine

HEGERLS builds rack-supported warehouses up to 40–45 meters tall, transforming land into vertical storage power.

A 5,000 m² plot can achieve the storage capacity of a traditional 20,000 m² warehouse.

Construction + Automation in One

Unlike conventional warehouses that add racks after building construction, HEGERLS integrates:

rack structure

steel frame

cladding

fire system

electrical control system

AS/RS stacker cranes

four-way shuttles

lifts

WMS

WCS

into a single engineering package.

This eliminates misalignment between construction teams, rack suppliers, and automation providers—one of the biggest pain points in warehouse projects.

Lower Investment, Shorter Delivery

Rack-supported warehouses optimize steel consumption and construction complexity, reducing both CAPEX and engineering time.

30–40% reduction in building cost

25–35% shorter delivery period

Construction + equipment commissioning done in one workflow

High-Density, High-Safety, High-Speed

The structure enables:

fully automated pallet handling

zero forklift inside the warehouse

dark warehouse operation

accurate traceability

energy-efficient cold storage

These advantages make HEGERLS a preferred partner for:

food & beverage manufacturers

pharmaceuticals

e-commerce and 3PL

new energy and battery factories

heavy manufacturing

FMCG and retail distribution

The HEGERLS Integrated Engineering Philosophy: "Warehouse Is Not a Building—It Is a System"

The company’s core strength lies in its ability to merge Chinese engineering principles with globle application scenarios:

Structural Precision Meets Automation Stability

HEGERLS adopts high-grade steel, precise rack assembly tolerances, and structural modules tailored for stacker crane operation and long-term load endurance.

Software-Driven Material Flow

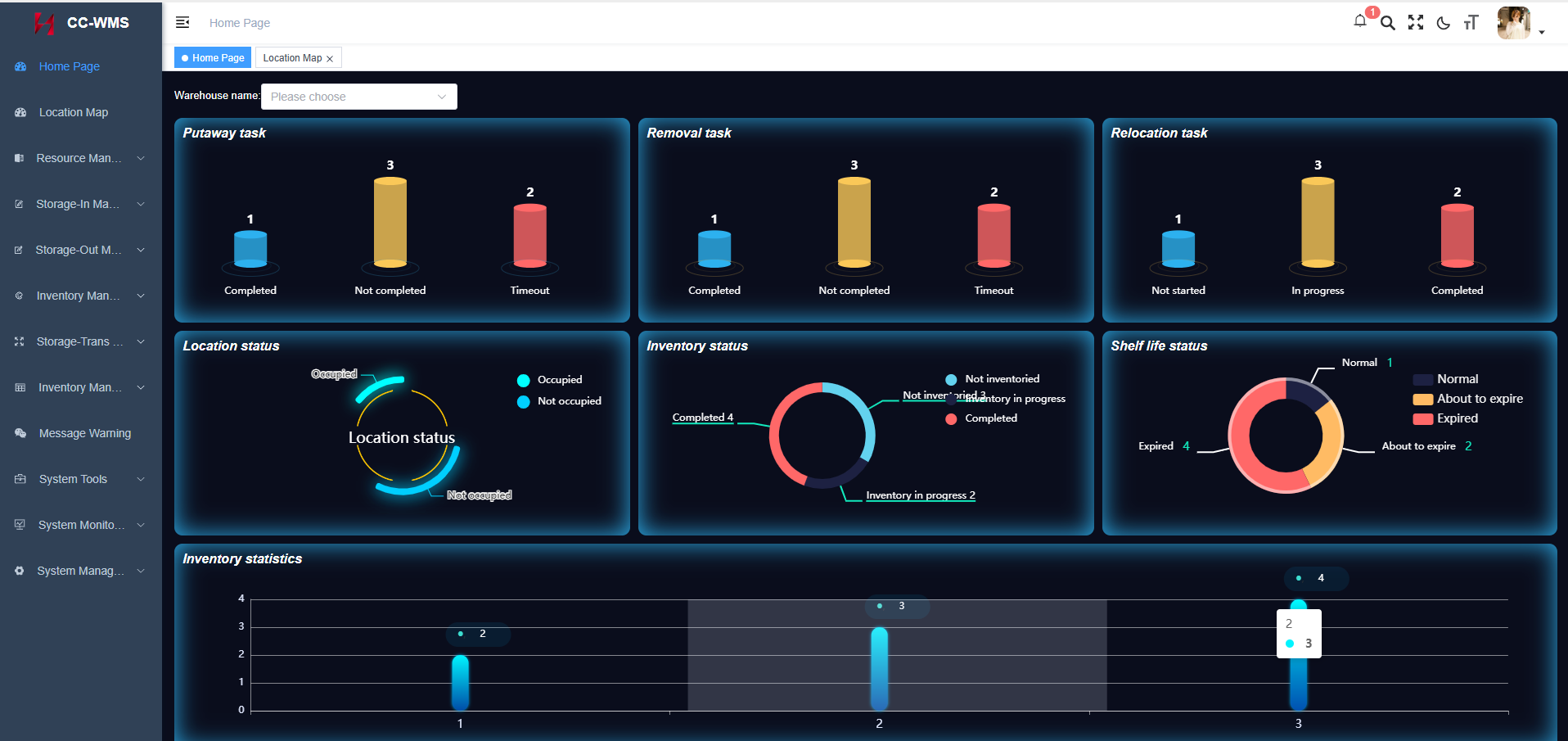

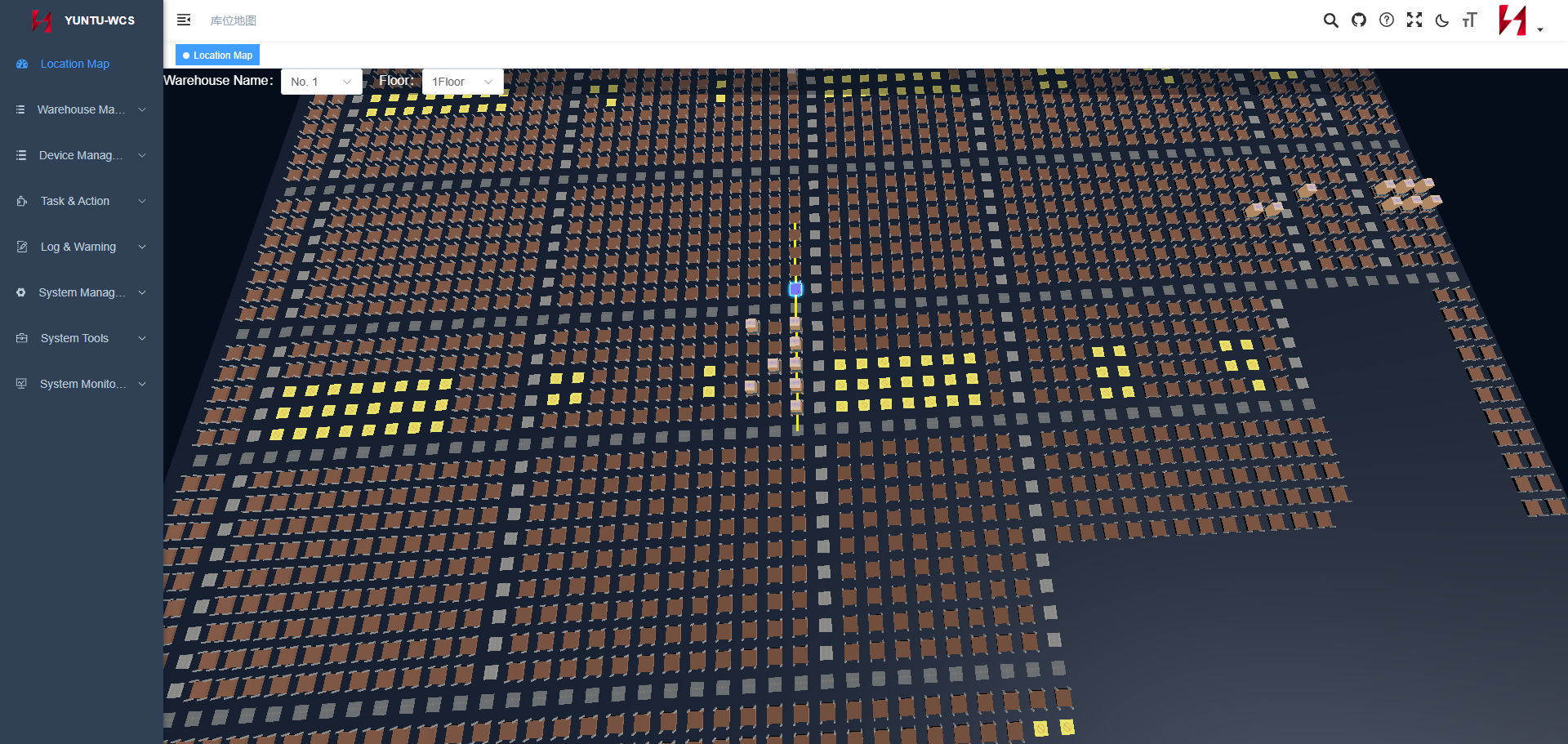

HEGERLS self-developed WMS/WCS act as the nerve system of the entire warehouse:

task optimization

routing control

load identification

inventory mapping

real-time monitoring

FIFO enforcement

temperature & environment tracking (for cold storage)

Every pallet carries a digital identity, enabling:

99.9% inventory accuracy

full-cycle traceability

millisecond-level device coordination

Automation Ecosystem

HEGERLS integrates multiple intelligent devices:

multi-layer lifts

multi-level conveyors

stacker cranes

shuttle carriers

automated docking stations

AGV/AMR for outbound areas

pallet AS/RS

shuttle-based mini-load systems

The result is a seamless ecosystem where tasks are autonomously executed and optimized.

Solving Real Manufacturing Pain Points: Case-Driven Innovation

HEGERLS project philosophy is always problem-first, technology-second.

Every major upgrade came from clients’ specific obstacles.

Case Example: Cold Storage Warehouse Upgrade

A food manufacturer faced:

–25°C working environment

rapid workforce turnover

extremely high cost of cold storage space

HEGERLS implemented a 40m rack-supported cold warehouse with shuttle + stacker crane combination:

labor reduced by 70%

outbound efficiency increased by 3x

energy consumption reduced by 30%

pallet accuracy reached 100%

Case Example: New Energy Battery Factory

Challenges included:

stringent safety requirements

space constraints

24/7 supply rhythm

HEGERLS delivered a combined clad-rack + stacker crane system that achieved:

continuous 24/7 pallet flow

40% higher storage density

zero forklift entry

transparent digital management

HEGERLS ability to transform chaotic front-end warehousing into stable, automated, and data-driven infrastructure has made it the backbone of many next-generation factories.

From Manufacturer to Infrastructure Provider: HEGERLS New Industry Positioning

Through years of engineering accumulation, HEGERLS is no longer just a supplier of storage equipment.

It has become a “core infrastructure builder” for modern manufacturing and logistics.

Its competitive advantages include:

End-to-end engineering capability (EPC level)

One-stop integration of racking + construction + AS/RS + software

Decades of automation experience

Solutions for both large enterprises and SMEs

Strong cost advantage compared with European counterparts

Fast response and localized technical support

This enables HEGERLS to stand out in a market where clients increasingly seek turnkey automated warehouse solutions rather than scattered components.

The Future: Rack-Supported Warehouses as the Foundation of Smart Manufacturing

In the era of industrial upgrading, factories require:

flexible storage

digital inventory

automated supply

real-time scheduling

safer manufacturing environments

HEGERLS sees rack-supported warehouses as the foundation layer upon which smart factories operate.

From storage to production, from data flow to material flow, HEGERLS aims to eliminate the boundaries between warehouse and workshop.

The philosophy is clear:

“When the warehouse becomes intelligent, the factory becomes predictable.

When storage becomes automated, production becomes stable.”

This vision has already helped clients achieve:

storage density doubled

manpower reduced by 50–80%

OPEX dramatically cut

production rhythm stabilized

ROI accelerated

Conclusion: HEGERLS Leads the Transformation of Front-End Warehouse Management

In a market filled with noise about robots and production automation, HEGERLS chose a more difficult—but more valuable—path: solving the toughest front-end warehousing problems.

By deeply integrating:

rack-supported structures

AS/RS automation

four-way shuttle systems

digital warehouse control software

engineering-grade construction capability

HEGERLS redefines what a modern warehouse can be.

Not a storage room.

Not a cost center.

But a vertical engine of efficiency— a structural, digital, and intelligent core of the entire factory. HEGERLS Rack-Supported Warehouses are not just buildings. They are the backbone of tomorrow’s smart manufacturing and logistics.

Need a smart warehouse? Contact us now to get your customized warehouse storage solutions.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955