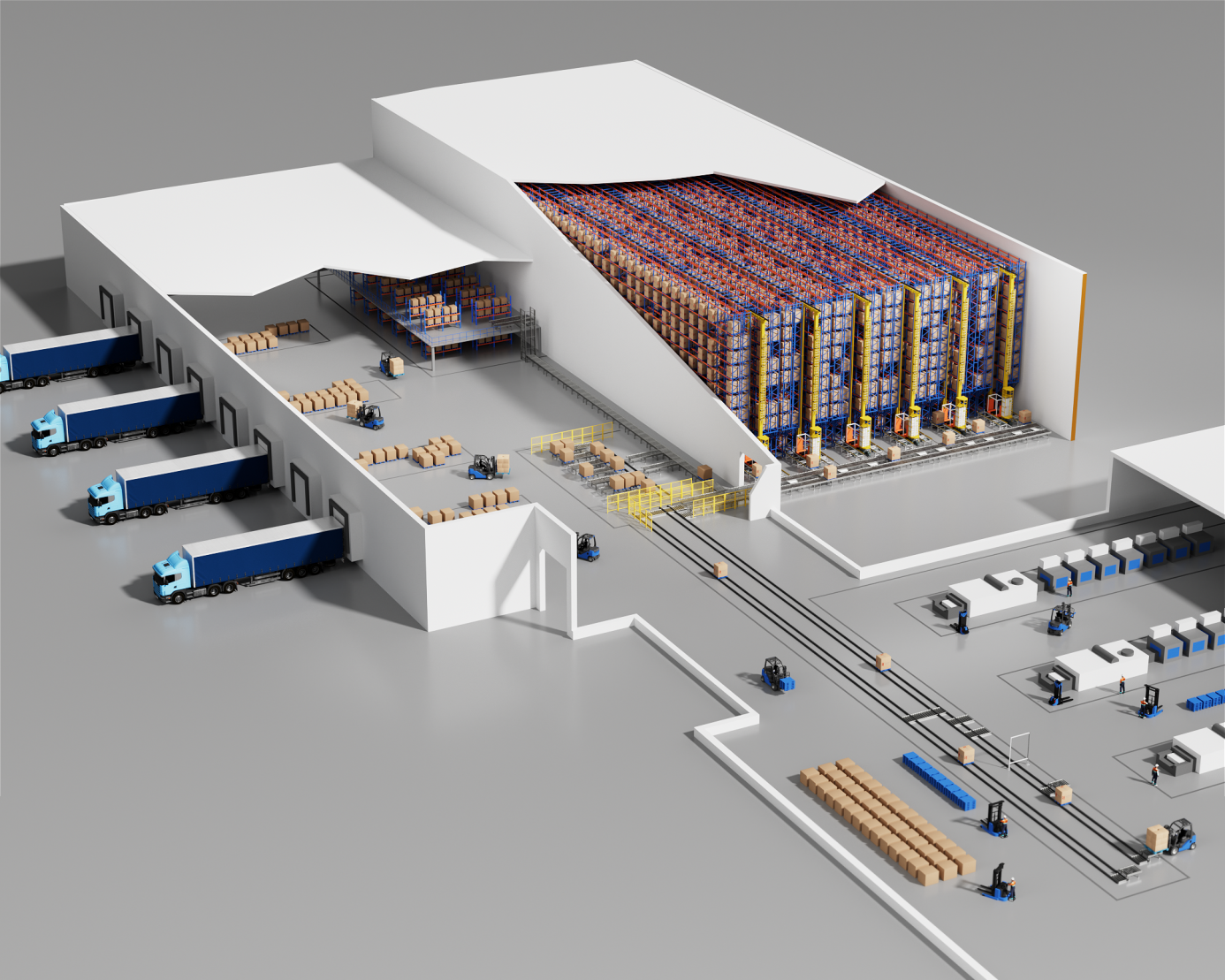

As global logistics intensifies and industrial land becomes increasingly scarce, companies are under pressure to expand vertically, automate faster, and reduce construction costs. Against this backdrop, clad-rack warehouses — storage buildings where the racking structure itself acts as the primary load-bearing framework — have become one of the fastest-growing solutions across manufacturing, cold chain, retail, and e-commerce operations.

Standing at the forefront of this transformation is HEGERLS, a leading Clad-Rack Warehouse Manufacturer, known for integrating structural engineering, automation technology, and warehouse digitalization into a single, high-performance storage ecosystem. With decades of experience in racking systems and automated solutions, HEGERLS is now delivering some of the world’s most efficient, cost-effective, and high-density clad-rack facilities.

What Is a Clad-Rack Warehouse or Rack-supported Warehouse?

A clad-rack warehouse is a building in which:

l The racking structure acts as the building’s frame,

l External walls and roofing are directly attached to the racks,

l The warehouse height is maximized, often reaching 25m–45m,

l Automation systems integrate seamlessly, including stacker cranes, shuttles, conveyors, and WMS/WCS.

This approach eliminates the need for traditional civil construction, significantly shortens project timelines, and creates a super-efficient high-density warehouse with minimal structural footprint.

Why Clad-Rack Warehouses Are Becoming a Global Trend

1. Higher Vertical Utilization

Clad-rack warehouses make it possible to extend storage height far beyond typical steel buildings, maximizing cubic utilization while minimizing land cost — a major advantage in dense industrial regions.

2. Lower Construction and Engineering Costs

Because the racks themselves serve as the structural skeleton, companies can:

l Reduce steel consumption for building frameworks

l Shorten construction time

l Lower labor and permitting costs

l Reduce total investment compared with conventional warehouses

3. Designed for Full Automation

Clad-rack warehouses are inherently compatible with:

l Stacker crane systems

l AMRs and AGVs

l Conveyor and sorting systems

This makes the facility future-proof and suitable for full digital transformation.

4. Superior Stability & Safety

Properly engineered clad-rack structures are capable of withstanding:

l Strong winds

l Seismic activity

l Temperature variation

l 24/7 automated operations with predictable load cycles

5. Energy Efficiency

Compared with traditional buildings, clad-rack structures often require less heating, cooling, and lighting, significantly lowering long-term operating costs.

HEGERLS: A Clad-Rack Warehouse Manufacturer with Full-Scope Engineering Strength

HEGERLS is one of the few companies in Asia capable of delivering true end-to-end clad-rack warehouse solutions.

Integrated Capabilities Include:

l Warehouse planning & layout design

l Racking system engineering and structural calculations

l Automated system integration (AS/RS, shuttles, conveyors, WMS/WCS)

l Building envelope design including walls and roofing

l Mechanical & electrical installation

l Global commissioning and after-sales support

This vertical engineering capability ensures unmatched consistency, project reliability, and execution efficiency.

Structural Engineering Behind HEGERLS Clad-Rack Warehouses

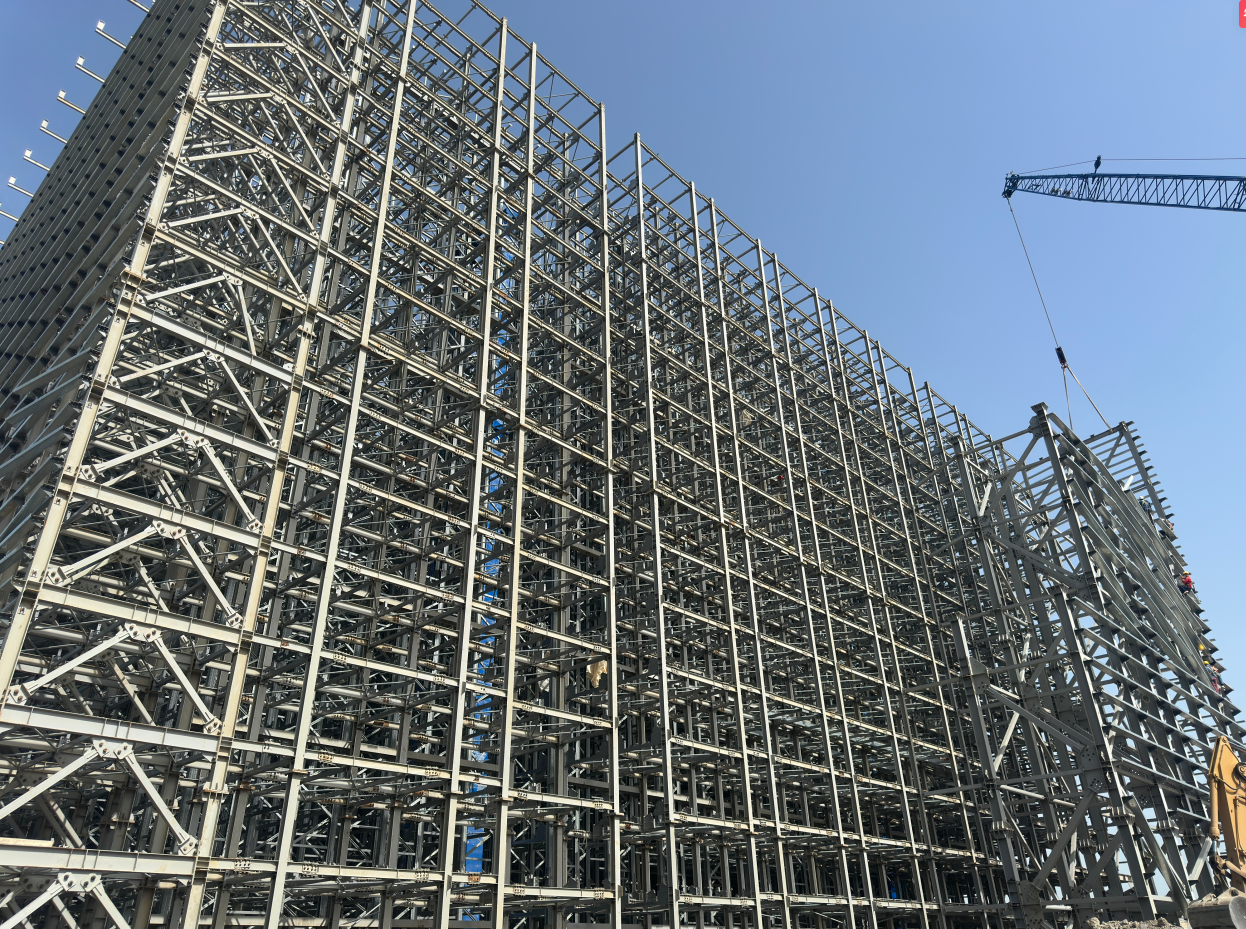

1. Load-Bearing Rack Framework

Using high-strength steel, HEGERLS designs racks that not only store pallets but also carry the weight of the building envelope, wind pressure, snow load, and seismic activity.

2. Precision Manufacturing Standards

All components benefit from:

l Automated laser cutting

l Robotic welding

l Strict coating and anti-corrosion treatments

l Multi-point quality inspection

Ensuring decades of stability and performance.

3. Customized Height & Layout

HEGERLS designs clad-rack warehouses ranging from 20m to 45m, tailored to:

l Pallet types

l Load capacity

l Throughput requirements

l Space limitations

4. Seamless Automation Compatibility

Every clad-rack project integrates automated systems such as:

l High-speed stacker cranes

l Four-way shuttle systems

l Pallet conveyors & lifts

l Automated pallet identification

l Digital warehouse management

Ensuring optimal flow, accuracy, and throughput.

Key Industries Choosing HEGERLS Clad-Rack Solutions

Cold Chain & Frozen Storage: Customers seeking temperatures of -18°C to -30°C prefer clad-rack AS/RS systems because they reduce cooling area and energy loss.

Food & Beverage Manufacturers: High SKUs, strict hygiene standards, and rapid turnover make clad-rack automation ideal.

3PL Operators: For logistics operators, fast construction and scalable automation deliver strong ROI.

Automotive & Industrial Parts: Heavy-duty load capacity and reliable seismic performance allow secure high-rise storage.

E-Commerce & Retail Fulfillment: The need for 24-hour operations and automated picking makes the technology increasingly essential.

HEGERLS Global Case Studies

Case 1 – Moroccan Tire Manufacturer Accelerates Expansion with HEGERLS Rack-Supported Warehouse

A tire manufacturer in Morocco upgraded its fast-growing operations with a HEGERLS rack-supported warehouse.

After on-site evaluation, HEGERLS delivered a high-density solution combining shuttle runner racks and stacker cranes. The system tripled storage capacity and tripled inbound/outbound efficiency.

The project features 35,496 pallet positions, 1465×1150×1130 mm pallet size, 1200 kg load capacity, and a 34.9 m warehouse height, significantly reducing construction costs while enabling fully automated, scalable warehousing.

Case 2 – Indian Food Company Upgrades Cold-Chain Storage with HEGERLS Four-Way Shuttle Rack-Supported Warehouse

An Indian food company specializing in meat and poultry exports upgraded its outdated traditional cold rooms as production and efficiency demands increased.

After a detailed assessment of its space limitations and high land costs, HEGERLS recommended a four-way shuttle rack-supported warehouse. The new system saves 20–30% of land usage, doubles storage capacity, and reduces cold-room labor costs by three times.

The project features 35,000 pallet positions, 1000×1100×1800 mm pallet size, 1400 kg load capacity, and a 32 m-high cold room, delivering a high-density, fully automated cold-chain storage solution.

Why Companies Choose HEGERLS as Their Clad-Rack Warehouse Manufacturer

Engineering Depth: From structural analysis to automation programming, HEGERLS provides unmatched professional expertise.

One-Stop Integration: Racking, building, automation, and software — all from one supplier.

Global Project Experience: Deployment across Europe, Asia, the Middle East, and the Americas.

High Customization Capability: Tailored for heavy loads, cold chain, high-rise buildings, and fast pallet turnover.

Strong Commitment to Safety: Every clad-rack system meets international design and safety standards, including EN codes and steel-structure requirements.

Future of Clad-Rack Warehousing: HEGERLS Roadmap

The next wave of innovation includes:

l Hybrid systems combining shuttles + stacker cranes

l AI-driven inventory forecasting

l Real-time digital twin monitoring

l Higher-speed shuttle integration for multi-access storage

l Energy-optimized structural envelopes

As automation continues to transform industrial storage, HEGERLS is investing heavily in R&D to push clad-rack performance to new heights.

Conclusion

The evolution of warehouse construction is shifting away from conventional steel buildings toward fully integrated clad-rack systems. As a leading Clad-Rack Warehouse Manufacturer, HEGERLS is delivering world-class high-rise storage solutions that combine structural engineering, smart automation, and intelligent software into a unified platform.

For companies seeking to maximize space, reduce costs, and accelerate automation deployment, clad-rack warehouses represent the future — and HEGERLS is at the forefront of this global transformation.

Contact HEGERLS now to get your customized clad-rack warehouse solutions.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955