As global warehouses push toward higher density, taller buildings, and deeper automation, rack supported warehouse design is rapidly moving from a niche engineering solution to a mainstream strategic choice. Instead of treating racking as storage furniture, more logistics developers are now treating it as the building itself.

This shift is not accidental. Rising land prices, stricter energy standards, and the growing demand for automated storage systems are fundamentally reshaping how warehouses are designed from the ground up.

What Is Rack Supported Warehouse Design?

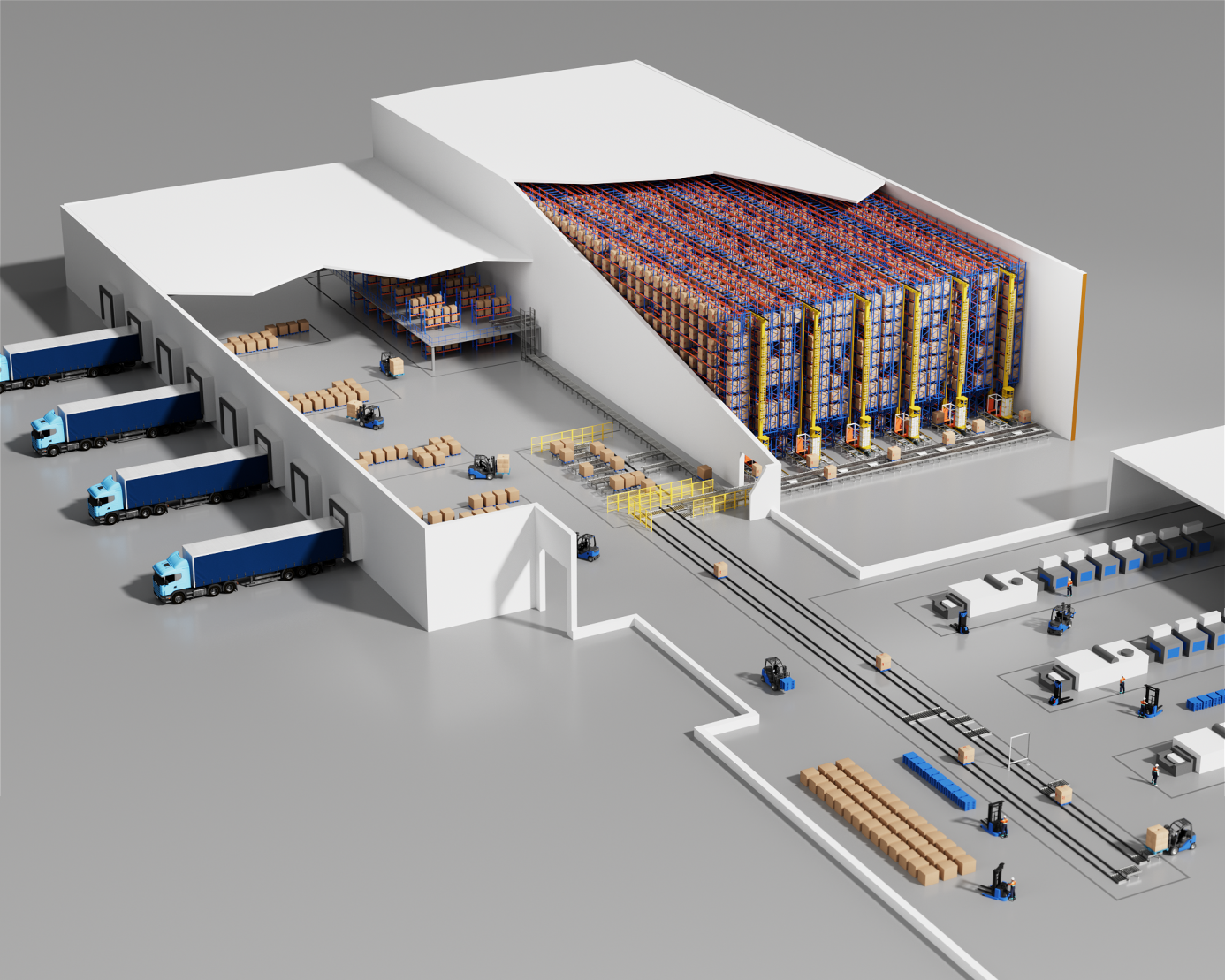

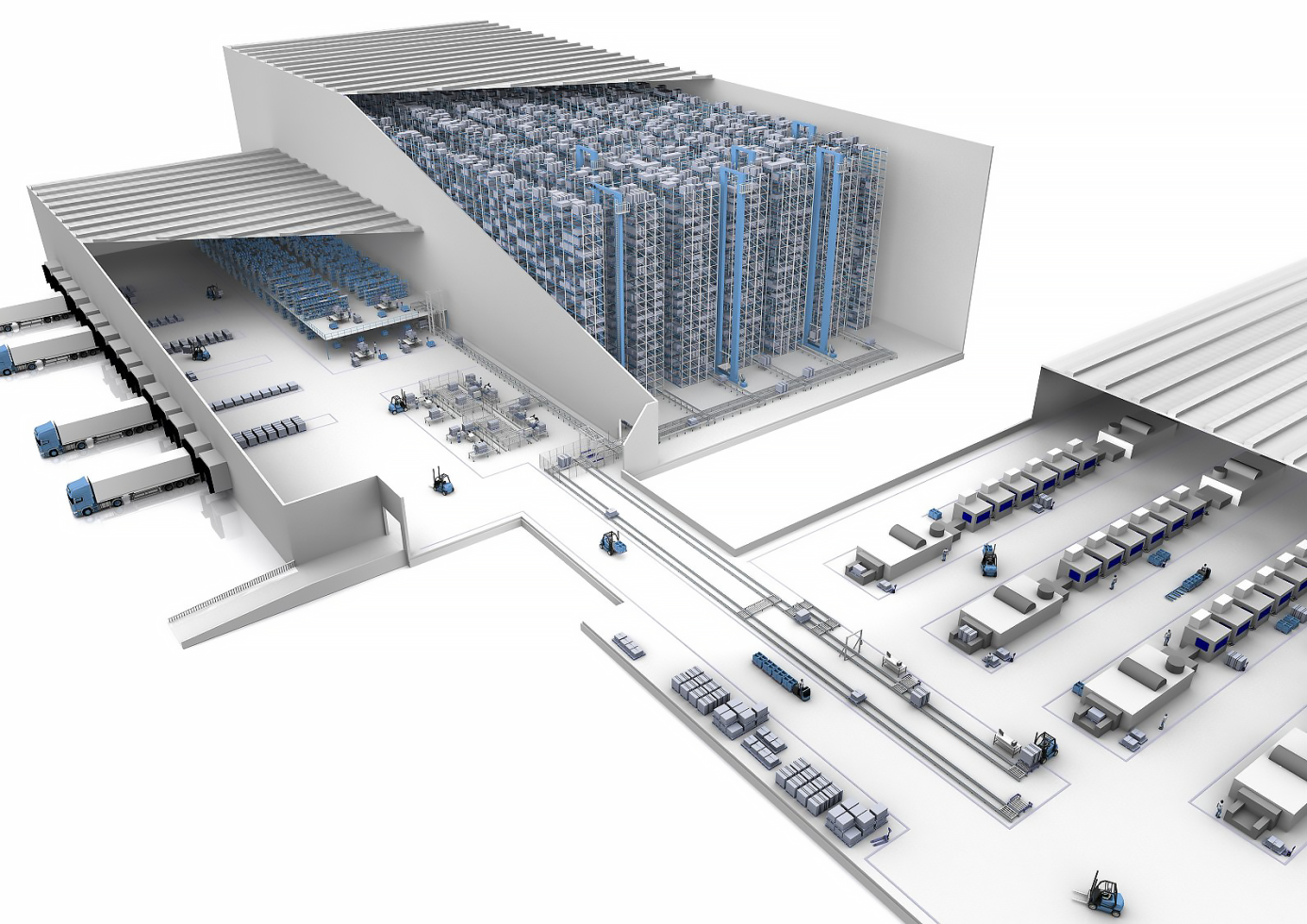

A rack supported warehouse (also known as a clad-rack warehouse) is a structure where the storage racking acts as the primary load-bearing framework for the building. The roof and wall cladding are mounted directly onto the rack structure, eliminating the need for traditional steel or concrete columns.

Unlike conventional warehouses—where racking is installed inside a finished building—rack supported designs integrate structure, storage, and automation into one engineered system.

Industry data shows that rack supported warehouses can reduce steel usage by 20–30% compared to conventional structures while enabling storage heights exceeding 30–40 meters, making them particularly attractive for high-density automation projects.

Why Are Rack Supported Warehouses Gaining Global Adoption?

Several converging trends are accelerating adoption worldwide:

l Urban land scarcity is pushing warehouses vertically rather than horizontally

l Automation systems (stacker cranes, shuttles, AS/RS) require tighter tolerances

l Cold storage growth demands thermally efficient, enclosed structures

l Energy costs are driving demand for compact, insulated building envelopes

According to multiple market studies, high-bay automated warehouses are growing at over 8% CAGR globally, with rack supported structures accounting for a growing share of new greenfield automation projects.

How Does Rack Supported Design Improve Storage Density?

One of the biggest advantages lies in eliminating redundant structures.

By removing internal columns and external building frames:

l Aisle layouts become more compact

l Vertical clearance is fully utilized

l Rack depth and height can be optimized for automation

In pallet-based systems, rack supported warehouses typically deliver 15–25% more pallet positions on the same footprint compared to conventional buildings with freestanding racks.

For operators handling high SKU counts or seasonal peaks, this density gain directly translates into lower cost per pallet stored.

Why Is Rack Supported Design Ideal for Automated Systems?

Automation thrives on precision—and rack supported warehouses are engineered for it.

Because the racking is designed together with automation equipment, tolerances for:

l Rail alignment

l Mast travel

l Shuttle positioning

l Seismic and wind loads

are all calculated at the structural design stage, not retrofitted later.

This makes rack supported warehouses especially suitable for:

l Stacker crane systems

l Four-way pallet shuttle systems

l Miniload AS/RS

l Shuttle + crane hybrid solutions

In automated environments, misalignment of even a few millimeters can reduce throughput or increase maintenance costs. Integrated design significantly reduces these risks.

How Does Rack Supported Design Perform in Cold Storage Environments?

Cold storage is one of the fastest-growing application areas for rack supported warehouses.

With global frozen and chilled food demand rising steadily, cold storage capacity is expected to grow at over 10% annually in some regions. Rack supported designs offer key advantages:

l Smaller building envelope reduces thermal loss

l Direct insulation attachment improves energy efficiency

l Faster construction minimizes exposure to temperature-sensitive timelines

In sub-zero environments (–18°C to –25°C), rack supported cold stores can reduce energy consumption per pallet by up to 15–20%, according to industry benchmarks.

What Engineering Challenges Must Be Addressed?

Rack supported warehouse design is not without complexity. Unlike conventional warehouses, structural, mechanical, and automation considerations are deeply interdependent.

Key challenges include:

l Load path calculation across racks, roof, and cladding

l Seismic and wind resistance, especially in high-bay designs

l Thermal expansion in temperature-controlled facilities

l Construction sequencing, as racks are erected before enclosure

This is why rack supported projects demand close collaboration between racking engineers, automation designers, and software integrators from the earliest concept stage.

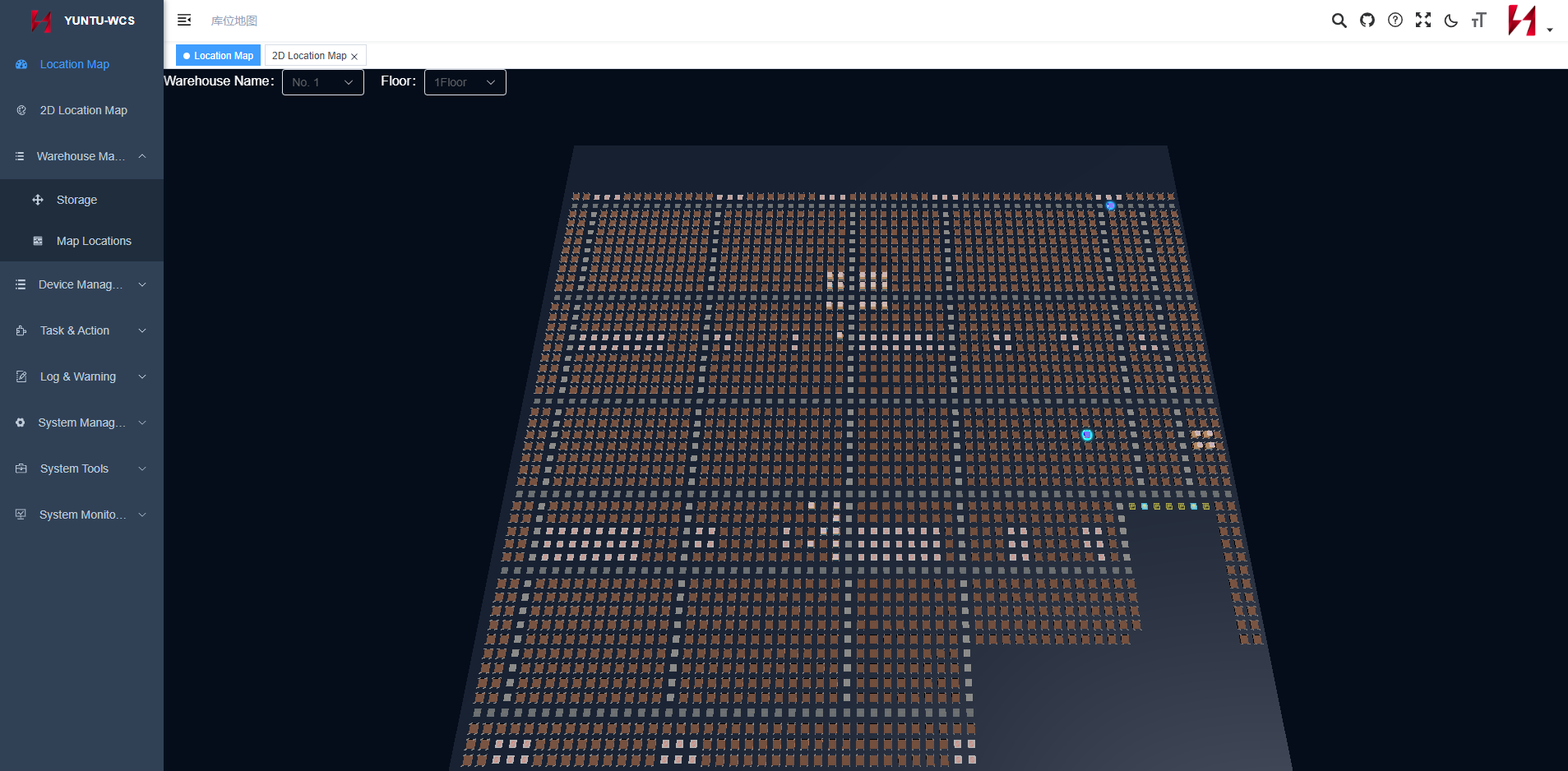

How Does Software Integration Influence Rack Supported Design?

Modern rack supported warehouses are no longer static storage systems—they are digitally orchestrated environments.

Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) influence:

l Slotting strategies

l Load distribution

l Throughput balancing

l Maintenance access planning

Designing rack geometry without considering software logic often leads to bottlenecks later. Advanced projects now treat software behavior as a structural design input, not an afterthought.

Is Rack Supported Design More Cost-Effective Over the Lifecycle?

While upfront engineering costs may be higher, lifecycle economics often favor rack supported warehouses.

Savings typically come from:

l Reduced building steel and foundations

l Lower land acquisition costs

l Improved energy efficiency

l Higher automation uptime

Over a 20–25 year lifecycle, many operators report double-digit percentage reductions in total cost of ownership, particularly in high-throughput or cold storage operations.

When Is Rack Supported Design the Right Choice?

Rack supported warehouses are best suited for operations that require:

l High storage height (20m+)

l Long-term facility commitment

l High automation penetration

l Stable SKU dimensions (especially pallets or totes)

They are less suitable for facilities requiring frequent structural modifications or low automation intensity.

How Is HEGERLS Approaching Rack Supported Warehouse Design?

From HEGERLS’s perspective, rack supported warehouse design is not a standalone product—it is a system-level solution.

By combining:

l Heavy-duty racking engineering

l Automated shuttle and stacker crane systems

l CC-WMS and YUNTU-WCS software

l Lifecycle service planning

HEGERLS approaches rack supported warehouses as integrated automation ecosystems, engineered for scalability, resilience, and long-term performance.

What Does the Future Hold for Rack Supported Warehouses?

Looking ahead, rack supported warehouse design is expected to evolve in three key directions:

1. Greater integration with shuttle-based automation

2. Higher structural heights driven by land scarcity

3. Deeper digital twins and predictive maintenance models

As automation becomes the default rather than the exception, the line between “warehouse” and “machine” will continue to blur—and rack supported design sits exactly at that intersection.

Planning a rack supported automated warehouse?

HEGERLS delivers integrated racking, automation, and software solutions designed for high-bay, high-density operations worldwide. Talk to HEGERLS Engineering Team.