Why the Role of the Automated Shuttle System Manufacturer Is Changing

As global supply chains accelerate and warehouse operations face rising pressure on land use, labor availability, and service-level agreements, automated shuttle systems have moved from “advanced option” to core infrastructure.

According to multiple industry analyses, shuttle-based automation is among the fastest-growing segments in warehouse automation, driven by e-commerce, cold storage, manufacturing logistics, and omnichannel distribution.

But as adoption grows, a new question is emerging among logistics decision-makers:

Is choosing an automated shuttle system about the equipment — or about the manufacturer behind it?

This shift is redefining what it means to be an automated shuttle system manufacturer.

What Defines an Automated Shuttle System Manufacturer Today?

In the past, manufacturers were evaluated primarily on hardware specifications: speed, payload, rail design, or battery life.

Today, the definition is broader.

A modern automated shuttle system manufacturer is expected to deliver:

l System-level design, not isolated machines

l Scalability across lifecycle stages, not fixed-capacity solutions

l Software integration capability, especially WMS/WCS coordination

l Operational resilience, not just peak performance

This evolution reflects how warehouses themselves have changed — from static storage facilities to dynamic fulfillment engines.

Why Are Shuttle Systems Becoming Central to High-Density Warehousing?

Industry data consistently shows that storage density and throughput per square meter are now critical KPIs for warehouse investments.

Shuttle systems directly address these priorities by enabling:

l Deep-lane, high-density pallet storage

l Flexible aisle configurations

l Multi-level operation independent of forklifts

Market research indicates that shuttle-based systems can increase storage density by 30–50% compared to conventional selective racking, especially in land-constrained or temperature-controlled environments.

This is why automated shuttle solutions are now widely deployed in:

l Cold storage warehouses

l Food & beverage distribution centers

l Automotive and spare parts logistics

l High-volume manufacturing buffer warehouses

How Do Manufacturers Differ Beyond the Shuttle Vehicle Itself?

1. System Architecture Capability

Not all manufacturers design complete shuttle ecosystems.

Advanced providers offer integrated solutions that combine:

l High-density racking structures

l Vertical transfer devices (lifts)

l Conveyor or pallet handling interfaces

This system-level approach reduces bottlenecks and enables balanced throughput across zones.

Shuttle vehicles

High-density racking structures

Vertical transfer devices (lifts)

Conveyor

2. Software Depth: WMS and WCS Integration

Warehouse automation is increasingly software-driven.

Manufacturers that can align shuttle systems with:

l Warehouse Management Systems (WMS) for inventory logic

l Warehouse Control Systems (WCS) for real-time task execution

offer significantly higher operational stability.

Industry surveys suggest that software integration issues account for over 40% of automation project delays, underscoring why manufacturer-side software competence matters.

3. Adaptability to Different Operating Environments

A true automated shuttle system manufacturer must support diverse environments, including:

l Sub-zero cold storage (down to -25°C)

l High-humidity food environments

l Heavy-load industrial applications

This requires expertise not only in mechanics, but also in:

l Material selection

l Energy management

l Redundancy and fault tolerance

What Are Buyers Really Looking for When Selecting a Manufacturer?

Is reliability more important than speed?

For many operators, the answer is yes.

Operational data shows that a 1% improvement in system availability can translate into thousands of additional order lines fulfilled per day in large facilities.

As a result, buyers increasingly prioritize:

l Mean time between failures (MTBF)

l Redundant shuttle routing strategies

l Predictive maintenance readiness

Do scalability and modularity influence long-term ROI?

Absolutely.

Warehouses rarely remain static. Order volumes fluctuate, SKUs expand, and business models evolve.

Manufacturers offering modular shuttle architectures allow operators to:

l Add shuttles incrementally

l Expand racking blocks without major downtime

l Upgrade software independently of hardware

This flexibility significantly reduces total cost of ownership over 10–15 years.

How Are Market Trends Shaping Automated Shuttle System Design?

Trend 1: Multi-Directional Shuttle Movement

Four-way and multi-directional shuttle systems are rapidly gaining traction, allowing:

l Cross-aisle movement

l Flexible storage and retrieval paths

l Reduced dependence on fixed transfer points

Industry forecasts suggest that multi-directional shuttle systems will outpace traditional single-direction shuttles in growth rate over the next five years.

Trend 2: Integration with Smart Racking Structures

Manufacturers are increasingly designing racking and shuttle systems as a single engineered unit, rather than separate components.

This approach improves:

l Structural stability

l Load distribution

l Seismic performance

It also enables rack-supported warehouse designs where the racking structure forms part of the building envelope.

Trend 3: Data-Driven Maintenance and Diagnostics

Predictive maintenance is becoming a baseline expectation.

Shuttle systems equipped with:

l Sensor-based monitoring

l Usage analytics

l Remote diagnostics

can reduce unplanned downtime by 20–30%, according to industry benchmarks.

What Role Does HEGERLS Play as an Automated Shuttle System Manufacturer?

From HEGERLS’s perspective, the future of shuttle automation lies in system intelligence, not isolated speed metrics.

HEGERLS approaches automated shuttle systems with three guiding principles:

1. System First, Equipment Second

Every project begins with:

l Storage profile analysis

l Throughput modeling

l Growth scenario simulation

The shuttle configuration is then designed to support long-term operational goals.

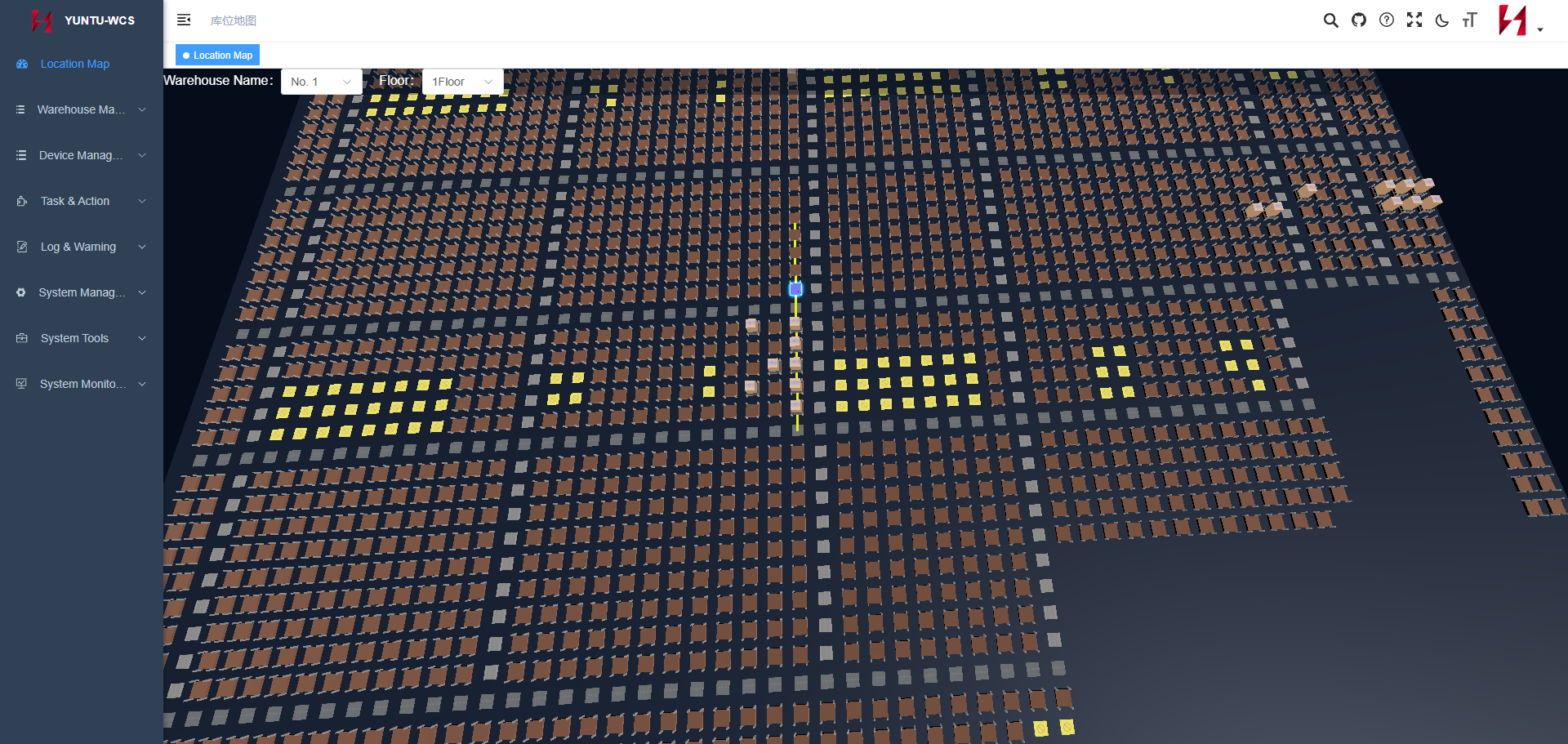

2. Native Integration with Control Software

HEGERLS shuttle systems are engineered to operate seamlessly with:

l CC-WMS (Warehouse Management System)

l YUNTU-WCS (Warehouse Control System)

This integration ensures synchronized decision-making between inventory logic and physical movement.

3. Designed for Real-World Constraints

From cold-chain logistics to heavy industrial storage, HEGERLS systems are built with:

l Environment-specific engineering

l Redundant operational paths

l Service-friendly modular components

This design philosophy reflects lessons learned from global deployment scenarios.

What Should the Future Hold for Automated Shuttle System Manufacturers?

Looking ahead, manufacturers will be evaluated not just on technology, but on strategic partnership capability.

Key expectations include:

l Faster deployment cycles

l Digital twins for system simulation

l AI-assisted task optimization

l Lifecycle support beyond commissioning

As automation becomes foundational to logistics infrastructure, the role of the automated shuttle system manufacturer will increasingly resemble that of a long-term operations partner, not a one-time equipment supplier.

Conclusion: Choosing the Right Manufacturer Is a Strategic Decision

Automated shuttle systems are no longer optional upgrades — they are core assets shaping warehouse competitiveness.

In this context, selecting the right automated shuttle system manufacturer means evaluating:

l System intelligence

l Software depth

l Scalability

l Operational resilience

For forward-looking logistics operators, the question is no longer whether to automate — but who to trust with building the automation backbone.

Planning a high-density automated warehouse or shuttle-based storage system?

Talk to HEGERLS specialists to explore how a system-level shuttle solution can support your throughput, scalability, and long-term operational goals.

Contact HEGERLS for a tailored automated shuttle solution.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955