Why Is the Warehouse Automation Landscape Rapidly Shifting?

Global warehousing is undergoing a structural transformation. Labor shortages, rising land costs, and the need for faster order fulfillment are pushing operators to rethink traditional storage models. Warehouses are no longer static storage spaces—they are becoming dynamic, data-driven fulfillment hubs.

Industry analysts estimate that the global warehouse automation market is growing at over 14% CAGR, with shuttle-based systems among the fastest-adopted technologies. Within this shift, four-way shuttle systems are increasingly viewed not as an alternative solution, but as a new industry standard for high-density automated storage.

What Is Driving the Adoption of Four-Way Shuttle Systems?

Four-way shuttle systems enable pallets to move in both longitudinal and transverse directions within a racking structure, separating horizontal transport from vertical lifting. This architectural shift allows warehouses to move away from fixed-aisle dependency and toward flexible, modular automation.

As supply chains become less predictable, adaptability has emerged as a decisive advantage—one that traditional automation systems often struggle to deliver.

How Do Four-Way Shuttle Systems Align with Modern Warehouse Requirements?

Is Flexibility Now More Important Than Maximum Throughput?

In the past, warehouses were designed around stable, forecastable demand. Today, SKU proliferation and seasonal volatility are the norm. Four-way shuttle systems allow operators to dynamically adjust throughput by adding or reallocating shuttles without reconfiguring the entire system.

Operational studies suggest that flexible automation can reduce peak-season bottlenecks by up to 35%, particularly in FMCG and e-commerce distribution environments.

Does High-Density Storage Still Matter in the Age of Automation?

Absolutely—especially as land prices continue to rise. Four-way shuttle systems support deep-lane storage and minimize aisle space, enabling 30–60% higher storage density compared to traditional selective racking or aisle-based AS/RS layouts.

This advantage is particularly critical in:

l Cold storage facilities

l Urban distribution centers

l Manufacturing buffer warehouses

Why Are Four-Way Shuttle Systems Replacing Traditional AS/RS in Many Projects?

Are Fixed Aisles Becoming a Limitation?

Traditional AS/RS relies heavily on fixed aisles, with one stacker crane typically serving each aisle. While reliable, this architecture limits scalability and creates potential single points of failure.

Four-way shuttle systems, by contrast:

l Share resources across storage zones

l Reduce dependence on individual machines

l Improve overall system resilience

Industry benchmarks show that system availability can improve by 10–15% when redundancy is built into shuttle-based designs.

How Does Modularity Influence Long-Term Investment Decisions?

Capital efficiency has become a central concern for automation buyers. Instead of committing to full capacity on day one, four-way shuttle systems allow staged investment.

This modular approach:

l Lowers initial CAPEX

l Aligns expansion with business growth

l Shortens financial payback cycles

Financial modeling indicates that incremental automation strategies can reduce investment risk by over 20% compared to fully fixed systems.

Which Industries Are Accelerating the Shift to Four-Way Shuttle Systems?

Is Cold Storage the Strongest Growth Segment?

Cold storage automation is expanding rapidly due to rising energy costs and strict food safety regulations. Operating in environments as cold as –25°C, automated shuttle systems minimize human exposure and maintain consistent performance.

Market research projects the global cold storage market to exceed USD 500 billion by the early 2030s, with shuttle systems playing a central role in new facility designs.

How Are Manufacturing and Spare Parts Warehouses Using Shuttle Systems?

Manufacturers increasingly rely on four-way shuttle systems to manage:

l High SKU diversity

l Irregular demand patterns

l Just-in-time production support

For spare parts warehouses, where accuracy and availability outweigh pure speed, shuttle systems provide the ideal balance between density and responsiveness.

What Role Does Software Play in Making Four-Way Shuttles the Standard?

Is Advanced WCS the Real Differentiator?

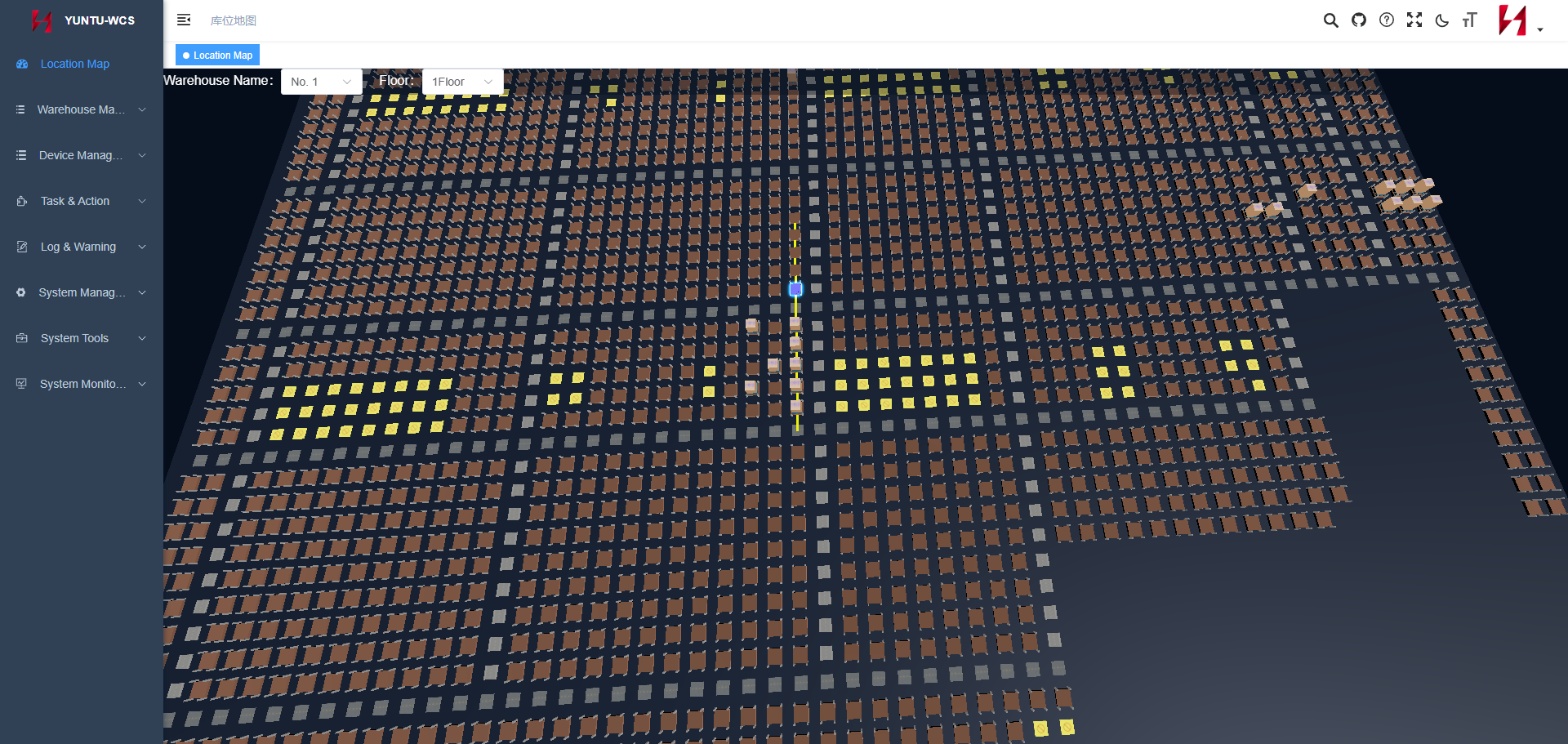

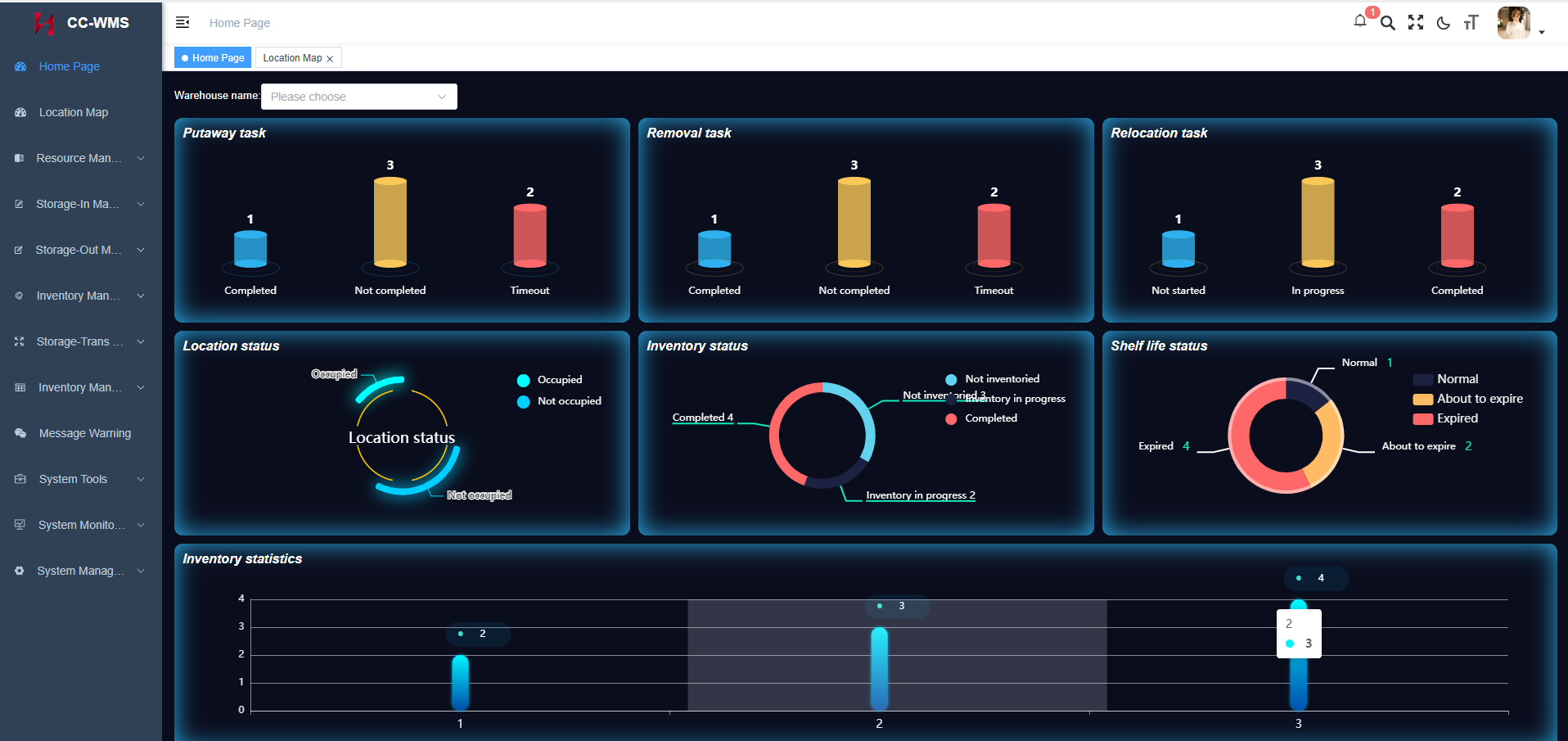

Four-way shuttle systems depend heavily on intelligent Warehouse Control Systems (WCS). These platforms coordinate shuttle routing, lift scheduling, and congestion management in real time.

Warehouses using advanced WCS logic report:

l 10–20% throughput improvements

l Reduced energy consumption

l More stable system performance under peak loads

How Does WMS Integration Enhance System Value?

A robust Warehouse Management System (WMS) ensures that inventory strategies align with physical movement. Together, WMS and WCS transform shuttle hardware into a fully optimized automation ecosystem.

Are Four-Way Shuttle Systems More Future-Proof?

How Do They Support Technology Upgrades?

As robotics, AI-driven optimization, and predictive maintenance mature, four-way shuttle systems provide a flexible platform for upgrades without structural disruption.

Their decoupled architecture makes it easier to:

l Introduce new shuttle generations

l Upgrade control software

l Adapt to evolving operational models

This future readiness is a key reason why many new automation projects now start with shuttle-based concepts.

What Challenges Should Be Considered Before Adopting Four-Way Shuttle Systems?

While powerful, four-way shuttle systems require:

l Precise system design

l Reliable software integration

l Experienced engineering support

Without proper planning, benefits such as density and flexibility may not be fully realized. Successful projects depend on system-level expertise rather than isolated equipment selection.

Conclusion: Why Four-Way Shuttle Systems Are Becoming the Industry Standard

Four-way shuttle systems reflect a broader shift in warehousing—from rigid, asset-heavy automation toward flexible, scalable, and data-driven solutions. Their ability to combine high-density storage, modular expansion, and intelligent control aligns perfectly with today’s operational realities.

As supply chains continue to evolve, it is increasingly clear that the future standard is not defined by fixed aisles or single machines, but by adaptable systems designed for change.

Looking to design a future-ready high-density warehouse?

Talk to HEGERLS automation specialists to explore how four-way shuttle systems can optimize your storage capacity, throughput, and long-term scalability.

Contact HEGERLS for a customized solution.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955