As global supply chains face rising land costs, labor shortages, and increasing SKU complexity, high-density storage has moved from a niche solution to a strategic priority for warehouses worldwide. From manufacturing plants to cold storage facilities and third-party logistics centers, companies are rethinking how space is used—and high-density storage is rapidly becoming the foundation of modern warehouse design.

Industry analysts estimate that warehouse land and construction costs have increased by 20–40% globally over the past decade, forcing operators to seek smarter ways to store more goods within the same footprint. In this context, high-density storage is no longer just about saving space—it is about competitiveness, scalability, and long-term operational resilience.

What Is High-Density Storage?

High-density storage refers to storage systems designed to maximize pallet or item capacity per square meter and per cubic meter, often by reducing aisle space, increasing vertical height, or leveraging automation.

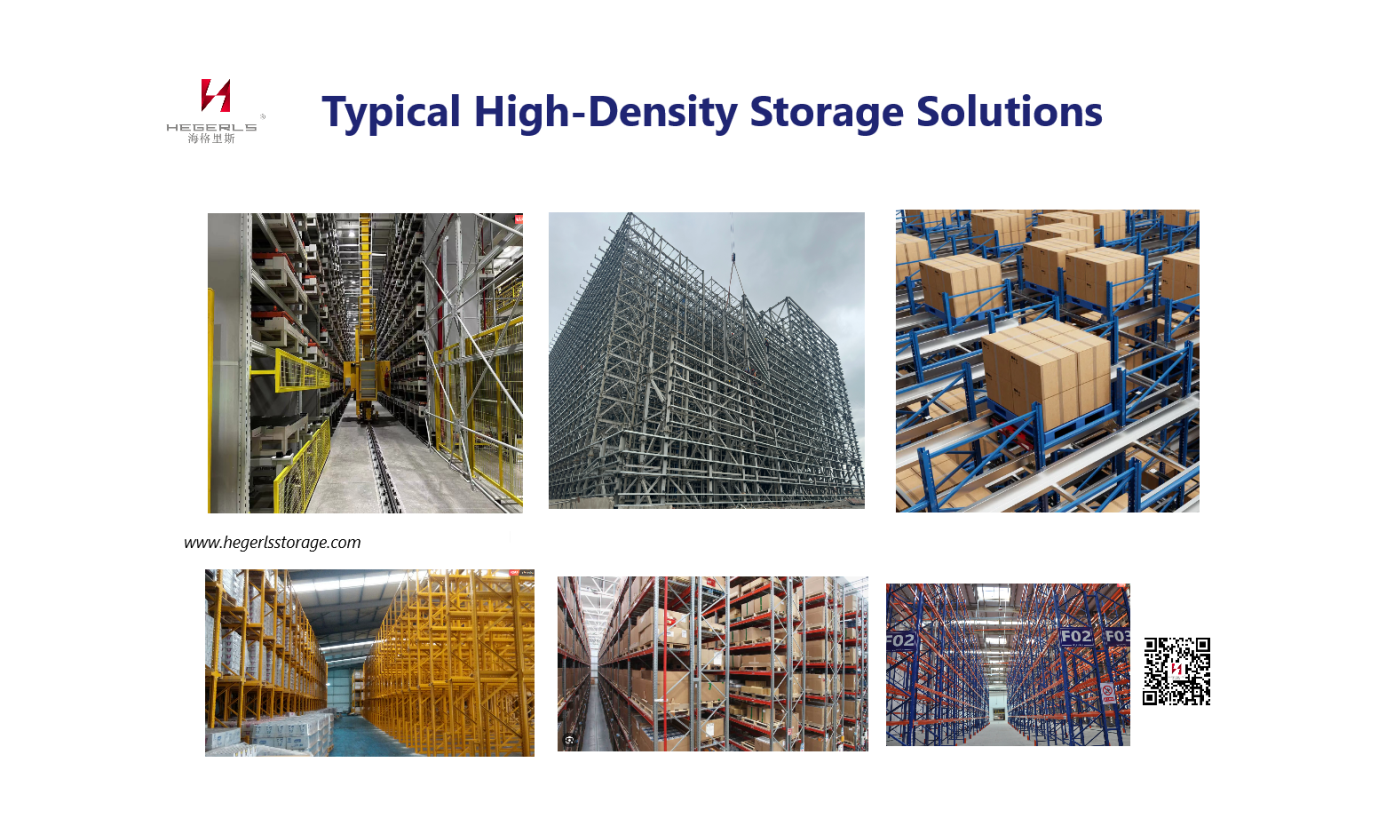

Typical high-density storage solutions include:

lShuttle-based racking systems

lDrive-in and push-back racking

lNarrow aisle storage

lRack supported warehouse designs

lAutomated Storage and Retrieval Systems (AS/RS)

Compared with conventional selective pallet racking, high-density systems can increase storage capacity by 30–60%, depending on layout and product characteristics.

Why Is High-Density Storage Becoming a Global Priority?

Several macro-level forces are accelerating the adoption of high-density storage worldwide.

Rising Land and Construction Costs

Industrial land scarcity is particularly acute in urban and coastal regions. In Asia-Pacific and Europe, logistics land prices have risen at nearly twice the rate of inflation, making horizontal expansion economically unviable for many operators.

SKU Proliferation

E-commerce and omnichannel distribution have dramatically increased SKU counts. Warehouses now need to store more product variations without expanding physical space.

Labor Constraints

With warehouse labor shortages reported in over 70% of developed logistics markets, operators are turning to dense, automation-friendly layouts that reduce manual handling.

How Does High-Density Storage Improve Space Utilization?

The core advantage of high-density storage lies in its ability to eliminate wasted space.

Key mechanisms include:

lFewer aisles through shuttle or deep-lane storage

lTaller racking structures using high-bay designs

lOptimized pallet flow based on inventory turnover

According to logistics engineering studies, high-density systems can achieve up to 90% space utilization, compared to 55–65% for traditional selective racking.

This improvement directly reduces cost per pallet position and increases return on warehouse investment.

What Role Does Automation Play in High-Density Storage?

Automation is increasingly inseparable from high-density storage strategies.

Automated solutions such as:

allow goods to move efficiently in dense layouts where forklifts would struggle or be unsafe.

Market research indicates that automated high-density warehouses can achieve:

l20–35% higher throughput

l30–50% labor cost reduction

lImproved inventory accuracy above 99%

These performance gains explain why automation investment continues to rise even amid economic uncertainty.

Is High-Density Storage Suitable for All Industries?

While not universal, high-density storage is particularly well-suited for industries with predictable pallet flows or high storage volumes.

Manufacturing: Supports bulk storage of raw materials and finished goods near production lines.

Cold Storage and Food Logistics: By reducing refrigerated air volume, high-density storage can lower energy consumption by 15–25%, a critical advantage as energy costs rise.

Third-Party Logistics (3PL): Allows service providers to maximize capacity within fixed facilities while serving multiple clients.

Automotive and Industrial Parts: Ideal for standardized pallets and repetitive inventory movements.

How Does High-Density Storage Affect Operational Efficiency?

Contrary to the assumption that denser storage slows operations, modern systems often improve efficiency.

Key factors include:

lShorter travel distances for automated equipment

lReduced congestion compared to forklift-based systems

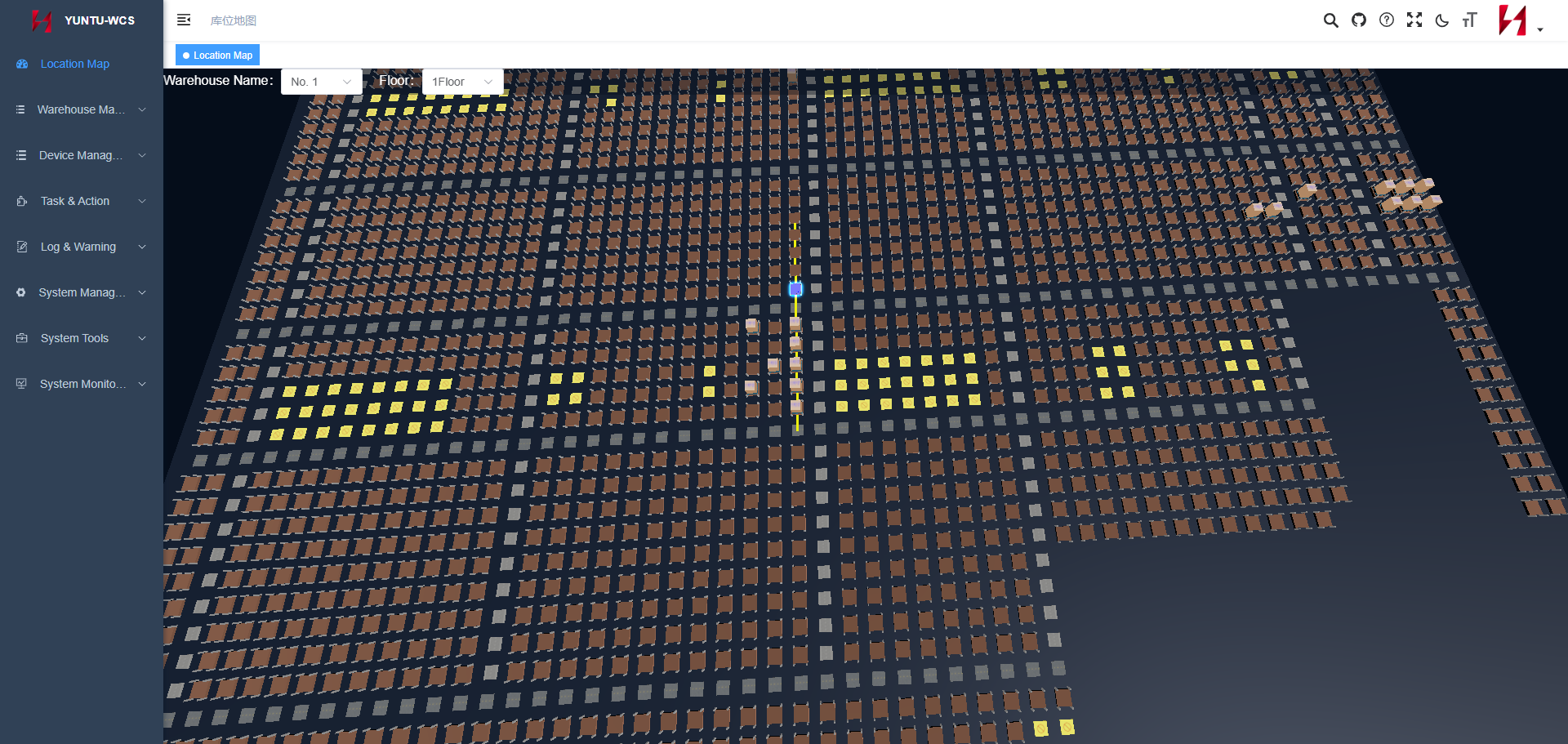

lSmarter slotting supported by WMS and WCS platforms

Industry benchmarks show that well-designed high-density warehouses can improve order fulfillment speed by 15–25%, especially when integrated with automation software.

WMS

WCS

What Are the Key Design Considerations for High-Density Storage?

Implementing high-density storage requires careful upfront planning.

Critical considerations include:

lSKU characteristics and turnover rates

lLoad weights and pallet dimensions

lFire safety and evacuation requirements

lFuture scalability and expansion

lIntegration with automation and software

Poorly planned dense systems can create bottlenecks, while well-engineered solutions deliver long-term operational advantages.

How Is High-Density Storage Shaping Warehouse Design Trends?

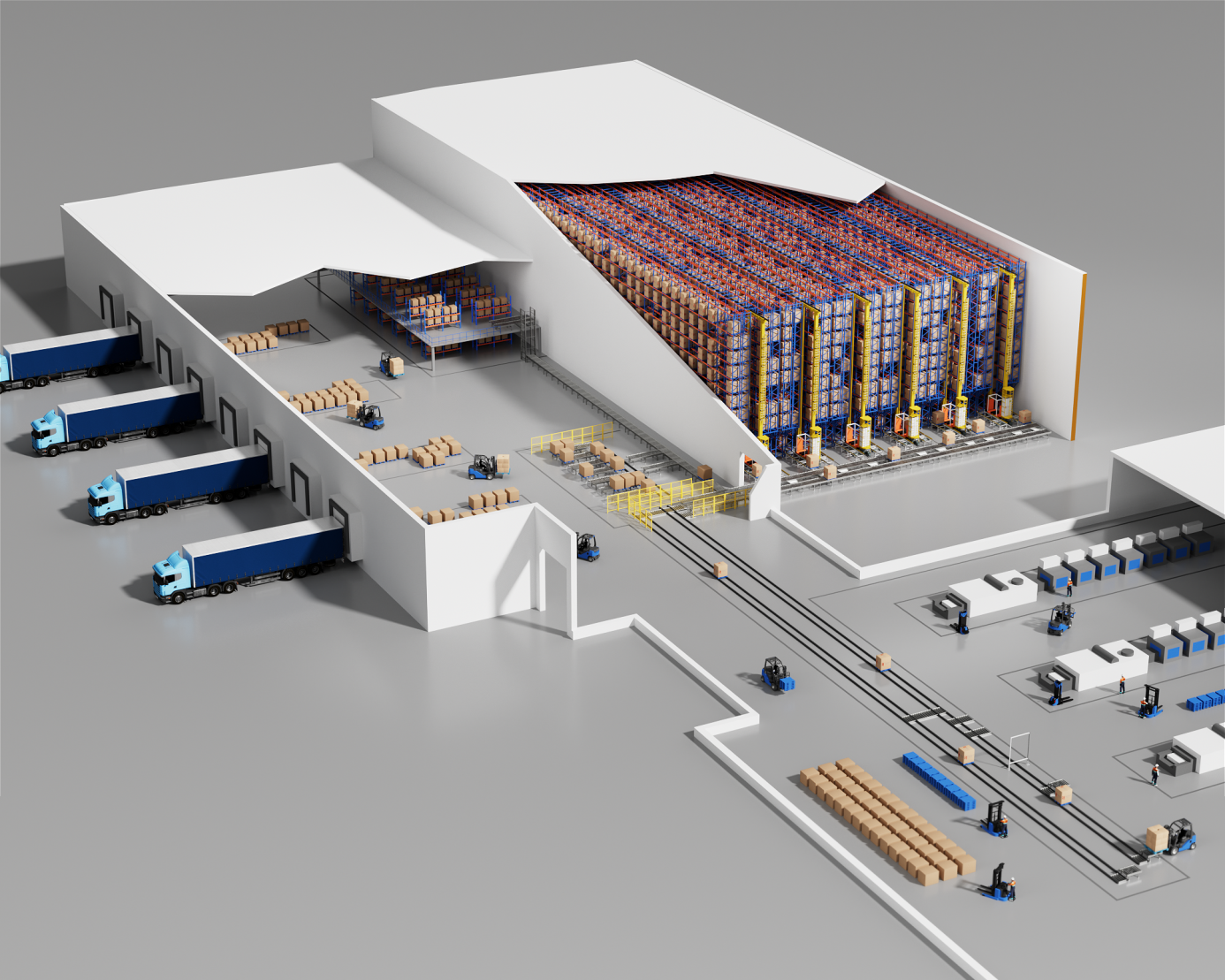

High-density storage is influencing warehouse architecture itself.

Emerging trends include:

lTaller buildings exceeding 30 meters

lRack supported warehouse structures

lReduced reliance on internal columns

lGreater integration between racking, automation, and software

Industry forecasts suggest that by 2030, more than 40% of newly built automated warehouses will prioritize high-density layouts as a core design principle.

How Does HEGERLS Support High-Density Storage Strategies?

HEGERLS approaches high-density storage as a system-level solution rather than a single product.

By combining:

lRack supported warehouse or clad rack warehouse

lAdvanced racking engineering

lShuttle and AS/RS technologies

lWarehouse Management Systems (WMS)

lWarehouse Control Systems (WCS)

HEGERLS enables customers to achieve higher storage density while maintaining safety, flexibility, and operational visibility.

This integrated approach reduces project risk and ensures that storage density gains translate into measurable performance improvements.

What Is the Long-Term Value of High-Density Storage?

Beyond immediate space savings, high-density storage delivers long-term strategic benefits:

lLower total cost of ownership

lImproved scalability without relocation

lStronger readiness for automation and digitalization

lEnhanced sustainability through reduced land and energy use

As supply chains continue to evolve, warehouses that fail to optimize space risk becoming cost centers rather than competitive assets.

Conclusion: Why High-Density Storage Is Redefining Modern Warehousing

High-density storage is no longer a specialized option—it is becoming the backbone of modern warehousing strategy. By enabling greater capacity, supporting automation, and reducing operational costs, it empowers companies to adapt to market volatility and future growth.

For organizations facing space constraints, rising costs, or increasing complexity, high-density storage offers a clear path forward.

Ready to transform your warehouse space into a high-performance asset? Contact HEGERLS to design a high-density storage solution built for today’s challenges and tomorrow’s growth.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955