As international logistics enters a new era of speed, scale, and automation, Warehouse Management Solutions (WMS) are becoming the backbone of modern warehouse operations. From real-time inventory visibility to automated task orchestration and robotics integration, WMS platforms are transforming how warehouses operate.

According to Market Research Future, the global WMS market is projected to reach USD 11.08 billion by 2030, growing at a CAGR of over 17%—a dramatic indicator of how essential digital warehouse solutions have become. For companies expanding into e-commerce, industrial manufacturing, or cold-chain logistics, the shift is clear: without advanced WMS, operational competitiveness rapidly declines.

In this article, we explore why Warehouse Management Solutions are gaining unprecedented traction, which technological trends are shaping the industry, and how HEGERLS is helping companies build smarter, data-driven warehouse ecosystems.

What Is Driving the Global Growth of Warehouse Management Solutions?

The rapid expansion of multi-channel logistics and demand for same-day or next-day delivery is changing warehouse expectations. Several industry forces are accelerating the adoption of advanced WMS platforms:

1. Surge in E-commerce Volumes

Global e-commerce sales surpassed USD 5.8 trillion in 2024, increasing pressure on warehouses to handle high SKU variety, shorter lead times, and complex order flows.

2. Demand for Real-Time Inventory Accuracy

Industry studies show:

l 69% of warehouses cite inventory accuracy as their #1 performance challenge

l Companies without digital inventory systems experience mis-pick rates up to 8%

3. Workforce Shortages in Logistics

Labor gaps continue to widen. The U.S. alone faces 500,000+ logistics job vacancies, increasing reliance on automation supported by WMS.

4. Growth of Automation Technologies

AMRs, AGVs, AS/RS, and shuttle systems require synchronized digital control—roles traditionally handled by WMS and WCS platforms.

These combined forces have pushed Warehouse Management Solutions from “helpful tools” to “mission-critical infrastructure.”

How Do Warehouse Management Solutions Improve Daily Operations?

Modern WMS platforms—especially those integrated with smart hardware—enhance nearly all aspects of warehouse operations.

1. Real-Time Inventory Management

With automated scanning, RFID, and digital tracking, WMS provides:

l 99%+ inventory accuracy

l Real-time stock level updates

l Automated replenishment alerts

l Precision slotting for faster picking

2. Optimized Pick, Pack, and Ship Workflow

WMS ensures the correct order sequence through:

l Wave picking & batch picking

l Digital picking routes

l Automated cartonization

l Packing verification

This reduces mis-picks and dramatically increases outbound throughput.

3. Improved Space Utilization

Through data-driven layout design, WMS can increase storage density by 20–40%, especially when combined with:

l Shuttle systems

l Vertical storage modules

l High-density racking

4. Automated Task Assignment

WMS orchestrates work across:

l Forklift operators

l AMRs

l Shuttle carriers

l Picking staff

l Replenishment teams

Tasks are automatically assigned based on real-time priorities.

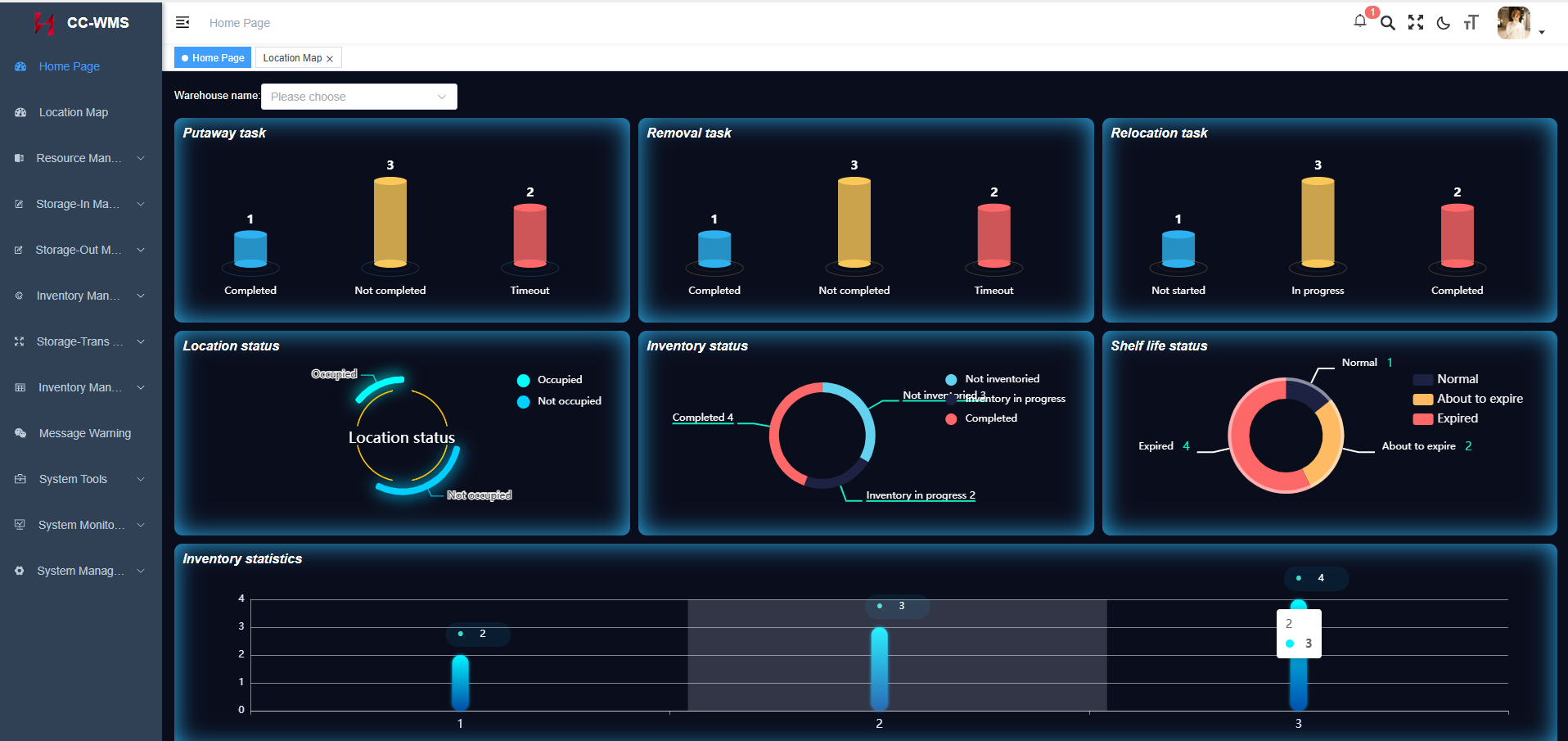

5. Data Analytics for Better Decisions

Dashboards provide key insights on:

l Picking performance

l Labor efficiency

l Inventory turnover

l Bottleneck identification

l Forecasting and planning

These insights allow managers to optimize operations with data—not guesswork.

What Are the Key Features of Next-Generation Warehouse Management Solutions?

The latest generation of WMS platforms are no longer simple inventory systems—they are intelligent decision-making engines.

AI-Powered Forecasting

Predictive algorithms estimate demand, minimizing stockouts and reducing excess inventory.

Integration With Robotics

WMS now coordinates:

l Four-way shuttle systems

l AGVs

l AMRs

l AS/RS stacker cranes

l Sortation equipment

Digital Twin Visualization

Facilities can simulate storage layouts, traffic flows, and capacity usage before deploying changes.

Cloud Deployment & Remote Access

Cloud-based WMS reduces hardware costs and enables remote monitoring across multiple sites.

IoT Connectivity

Sensors monitoring temperature, vibration, and machine performance feed data into WMS dashboards.

How Do Warehouse Management Solutions Support Automation Growth?

Automation is reshaping global warehousing—and WMS is the command center enabling it.

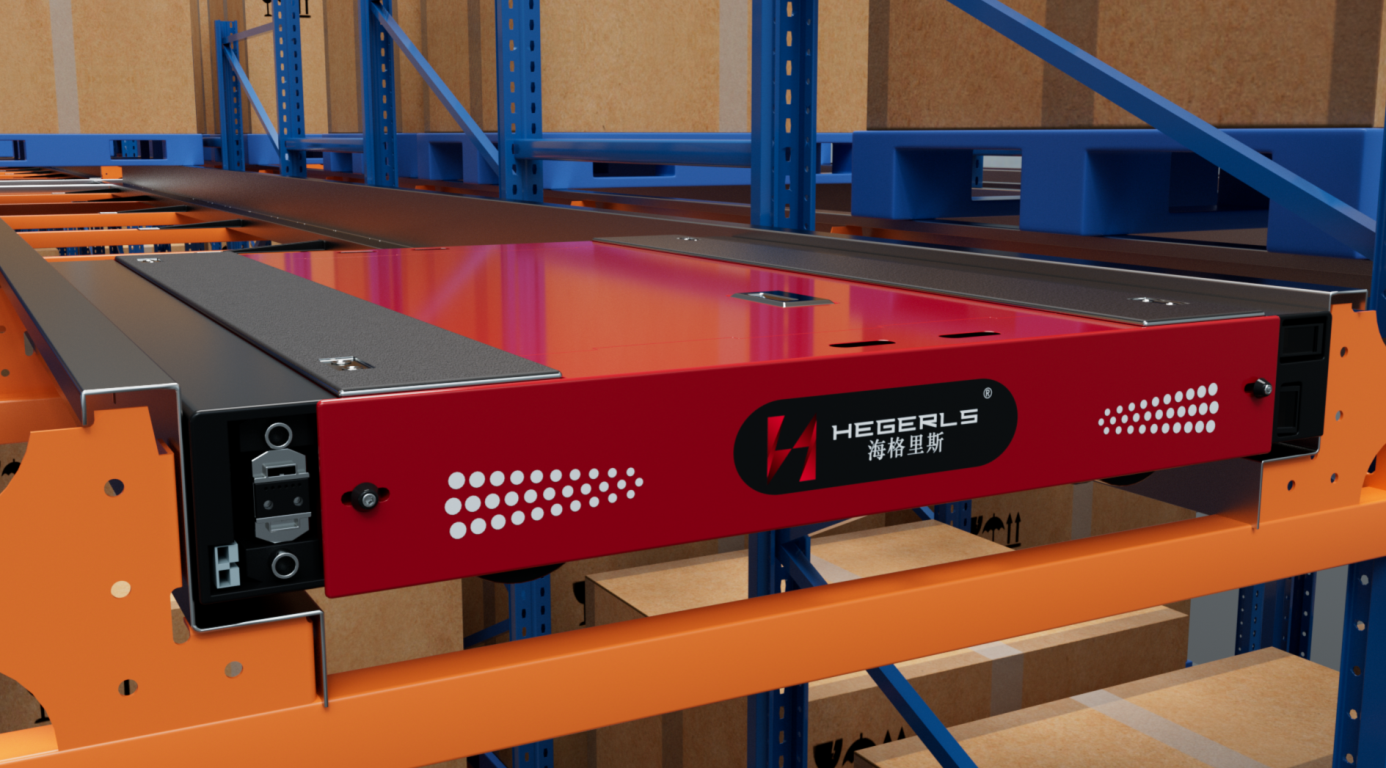

WMS + Shuttle Systems

Shuttle carriers rely on WMS for:

l Location assignment

l Order sequencing

l Multi-level coordination

WMS + Stacker Cranes

Automated cranes retrieve goods based on WMS-generated commands.

WMS + AMRs/AGVs

Robots require digital maps and routing instructions generated by WMS for:

l Picking

l Transport

l Zone-to-zone movement

WMS + Conveyor Sorting

For large e-commerce warehouses, WMS directs each parcel’s sorting destination in milliseconds.

What Challenges Do Warehouses Face Without Modern WMS?

Warehouses operating with outdated or manual systems often experience:

l High inventory errors (up to 20%)

l Picking inefficiencies

l Excessive workforce dependency

l Poor inbound/outbound coordination

l Limited visibility across multiple locations

l Slow response to demand peaks

These challenges directly affect cost, speed, and customer satisfaction.

How Is HEGERLS Supporting Global Warehouses With Smart WMS Deployment?

HEGERLS provides a complete portfolio of warehouse management solutions that integrate seamlessly with automated storage systems.

1. Customized WMS Architecture

HEGERLS analyses industry, inventory type, and growth strategy to build tailored WMS workflows.

2. Seamless Hardware Integration

HEGERLS WMS connects with:

l High-density racking

l AGVs/AMRs

3. Multi-Site Visibility

Large enterprises gain centralized control over inventory across different countries or regions.

4. Data-Driven Optimization

Smart dashboards guide decisions on replenishment, labor allocation, and equipment usage.

5. Strong Security & Compliance

Encryption, access control, and audit tracking ensure safe digital operations.

What Industries Benefit the Most From Advanced Warehouse Management Solutions?

E-commerce & Retail: High SKU variety requires fast replenishment and accurate picks.

Manufacturing: Real-time inventory ensures uninterrupted production.

Cold Chain Logistics: Temperature and traceability tracking are critical.

Third-Party Logistics (3PL): Multi-client operations rely heavily on multi-layered WMS systems.

Automotive & Industrial Parts: Thousands of SKU variations require accurate digital organization.

Why Are Companies Moving Toward Unified Digital Warehouse Ecosystems?

Businesses now recognize that WMS cannot operate in isolation. Instead, leading warehouses are building integrated ecosystems involving:

l ERP

l WMS

l WCS

l MES

l Automation systems

l Robots

l IoT sensors

Unified digital ecosystems increase transparency and operational speed while reducing total cost of ownership.

Conclusion: Why Warehouse Management Solutions Are No Longer Optional

As warehouse complexity increases and customer expectations shift toward instant delivery and precision accuracy, Warehouse Management Solutions have become indispensable. With automation on the rise and global supply chains undergoing rapid transformation, the future belongs to digitally managed, data-driven warehouses.

For businesses planning to scale, reduce errors, increase throughput, or integrate automation, the message is clear: the journey begins with modern WMS.

Ready to transform your warehouse into a smarter, faster, more efficient operation? Contact HEGERLS today for customized warehouse management solutions designed to support automation, growth, and real-time visibility.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955