As manufacturing, construction, and metal-processing industries expand across global markets, warehouses are encountering a rapid increase in oversized and irregularly shaped goods. From lumber and steel pipes to furniture panels, profiles, and heavy tooling components, long-load storage needs are rising faster than ever. In response, cantilever racking systems—known for their open-front structure and unparalleled flexibility—are emerging as one of the most in-demand warehouse racking solutions of 2025.

A recent report from Allied Market Research revealed that the global warehouse racking market is projected to surpass USD 17.1 billion by 2032, with the cantilever racking segment experiencing one of the highest growth rates due to rising long-item storage requirements. HEGERLS, a leading provider of advanced smart warehouse equipment and racking solutions, is seeing this same trend reflected across its customer inquiries and project delivery.

In this news update, we explore why cantilever racking is gaining renewed industry attention and how HEGERLS is helping global facilities upgrade to safer, more efficient storage for long and bulky materials.

Why Is Cantilever Racking Becoming a Critical Solution for Long-Load Storage?

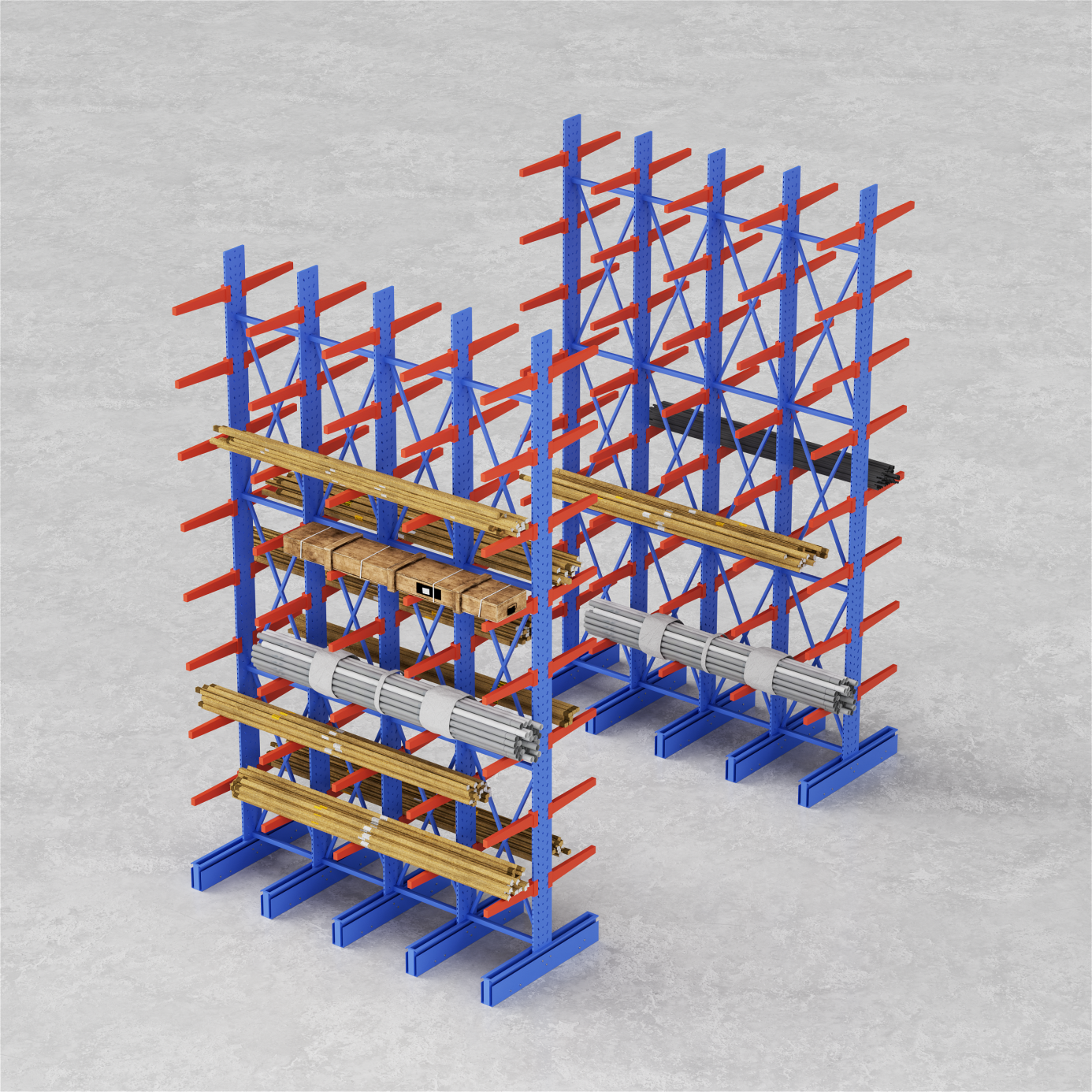

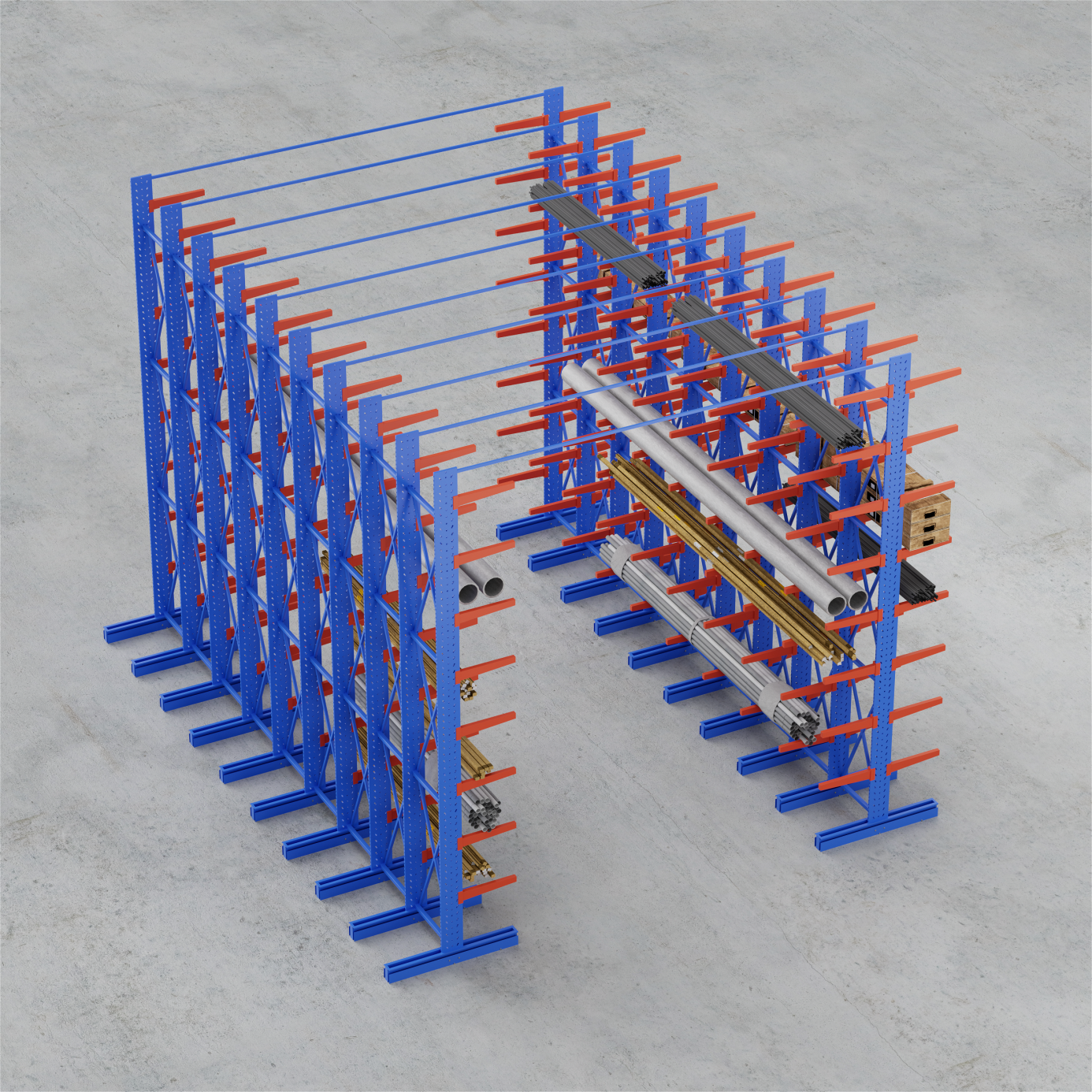

Cantilever racking is specifically engineered to store oversized materials that cannot fit into standard pallet racking. With no front columns and fully adjustable arms, it offers more flexibility, easier loading, and higher space utilization than traditional racking systems.

Several factors are accelerating adoption worldwide:

1. Growth of Construction and Infrastructure Projects

Global construction spending is expected to reach USD 15.5 trillion by 2030 (Oxford Economics), driving massive demand for steel profiles, wood, panels, and building materials—all of which require long-load storage.

2. Surge in Manufacturing Output

The manufacturing sector has seen a consistent 3–6% annual growth in Asia, Europe, and North America. Manufacturers increasingly require storage for pipes, extrusions, automotive beams, machine components, and more.

3. Shift Toward Warehouse Specialization

To stay competitive, warehouses are optimizing specific zones for long materials, reducing handling time and improving safety compliance.

4. Safety Regulations Growing More Strict

More companies now adopt racking systems that minimize tipping hazards and improve forklift maneuvering space—making cantilever racking the safer alternative.

These macroeconomic forces indicate why cantilever systems are no longer just optional; for many facilities, they are becoming operationally essential.

What Makes Cantilever Racking More Efficient Than Traditional Pallet Racks?

Traditional pallet rack beams block the front of each storage lane. For standard pallets, this is useful; for long or oversized materials, it becomes a limitation. Cantilever racking eliminates these constraints.

Open-Front Design: Allows forklifts and side-loaders to access materials from the front without obstruction.

Adjustable Cantilever Arms: Arms can be repositioned to support different product dimensions or changing inventory.

High Weight Capacity: Heavy-duty arms and columns can support extremely heavy materials like steel coils or industrial tooling.

Custom Length & Height Options: Racks can be tailored to height, arm length, and spacing needs, making them adaptable for any facility.

Indoor or Outdoor Use: Galvanized steel options support outdoor storage yards—common in lumber and steel distribution.

What Types of Materials Are Best Stored with Cantilever Racking?

Cantilever systems are optimal for:

Steel pipes and metal tubes

Wood panels and lumber

Sheet metal and extrusion profiles

Furniture boards

Long or oversized cartons

Building materials

Plastic pipes and PVC

Mold frames and tooling equipment

This versatility explains their growing popularity among wholesalers, industrial factories, and construction material suppliers.

How Has HEGERLS Improved Cantilever Racking for Modern Warehouses?

HEGERLS combines structural engineering expertise with warehouse automation capabilities to create cantilever racking systems that outperform traditional designs.

Engineering for Higher Load Capacity

HEGERLS racks use reinforced uprights and precision-calibrated arms to support heavier industrial loads safely.

Greater Customization

From single-sided outdoor racks to multi-level indoor heavy-duty systems, HEGERLS offers tailored configurations based on the product’s length, weight, and handling method.

Integration With Automated Handling Equipment

As more facilities use AGVs, AMRs, and side-loader forklifts, HEGERLS designs cantilever systems compatible with automated navigation and safe turning radii.

Corrosion-Resistant Finishes for Harsh Environments

Powder coating, hot-dip galvanizing, and sealed surface treatments ensure long life even in outdoor or high-humidity environments.

Enhanced Safety Features

Optional arm locks, end stops, column reinforcements, and anti-tilt structures significantly reduce collision and fall risks.

How Are Global Markets Driving New Demand for Cantilever Racking?

Construction Materials Industry: Lumber demand increased by over 28% globally from 2020 to 2024, directly boosting long-load storage needs.

Steel Distribution: Steel pipe consumption is expected to grow by 4.3% annually through 2030, requiring safer, higher-density racking systems.

Furniture Manufacturing: Growth of e-commerce furniture deliveries has increased demand for large-panel storage solutions.

Logistics & 3PL Providers: 3PLs now store a wider mix of oversized items, driving interest in flexible, adjustable cantilever structures.

Why Are Companies Replacing Old Racking Systems with Cantilever Racks?

Many warehouses still use makeshift or improvised storage methods such as floor stacking or non-specialized pallet racks. These methods reduce safety compliance and waste up to 60% of vertical space.

Companies are upgrading because:

Cantilever racks increase storage density

Improve material accessibility

Reduce product damage

Boost workflow efficiency

Lower long-term operating costs

In many HEGERLS projects, customer storage capacity increased 35–70% after switching to cantilever systems.

What Challenges Do Warehouses Face When Managing Long Materials?

Before implementing cantilever racking, facilities often struggle with:

Excessive forklift travel distance

Dangerous stacking practices

Limited visibility for operators

Damaged materials due to improper support

Difficulty handling long goods in narrow aisles

HEGERLS addresses these challenges with engineered layouts and optimized cantilever configurations.

How Does HEGERLS Support Facilities Transitioning to Cantilever Systems?

HEGERLS provides complete project support including:

Site measurement and engineering drawings

Load-bearing and structural analysis

Racking manufacturing & quality control

On-site installation

Periodic safety inspections and maintenance

This full-service approach is valued by customers from Europe, the Middle East, and Southeast Asia.

Conclusion: Why Cantilever Racking Will Continue to Lead Long-Load Storage Solutions

As global industries expand, the demand for secure, efficient storage of long and irregular goods continues to grow. Cantilever racking has become the preferred choice for warehouses that require flexibility, durability, and optimized space use. With expertise in heavy-duty industrial racking and automated warehouse systems, HEGERLS remains at the forefront of delivering customized cantilever solutions for customers worldwide.

Need a better solution for storing long and bulky materials? Contact HEGERLS to get a tailored cantilever racking design that maximizes safety, space, and handling efficiency.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955