Global warehouses are entering a new era of vertical expansion as Automated Vertical Storage Systems (AVSS) continue to gain widespread interest across manufacturing, logistics, 3PL, e-commerce, spare parts distribution, and cold chain facilities. With rising land costs, soaring order volumes, and the ongoing demand for compact yet high-density storage, many industries are now accelerating the deployment of automated vertical solutions to maximize cubic space and streamline material flow.

As an innovation-driven smart warehousing manufacturer, HEGERLS reports a significant uptick in inquiries and project discussions related to vertical storage modernization—reflecting a clear shift in how global operators think about space, automation, and operational efficiency.

Why Automated Vertical Storage Systems Are Becoming Essential

Traditional warehouses have long focused on horizontal expansion. However, rising operational costs and the pressure to increase order responsiveness have pushed facility operators to rethink layout strategy.

Automated Vertical Storage Systems introduce several fundamental advantages:

Better Use of Vertical Space

Warehouses with ceiling heights above 8 meters can unlock 30%–80% additional storage capacity by reorganizing materials into vertical towers. This dramatically improves the total storage density without requiring new construction.

Faster and More Accurate Retrieval

Powered by intelligent lifting modules, AVSS solutions reduce search time, walking distance, and manual handling. Operators can access items with a single command, achieving:

lFaster pick cycles

lImproved picking accuracy

lReduced labor fatigue and human error

Full Integration with WMS/WCS

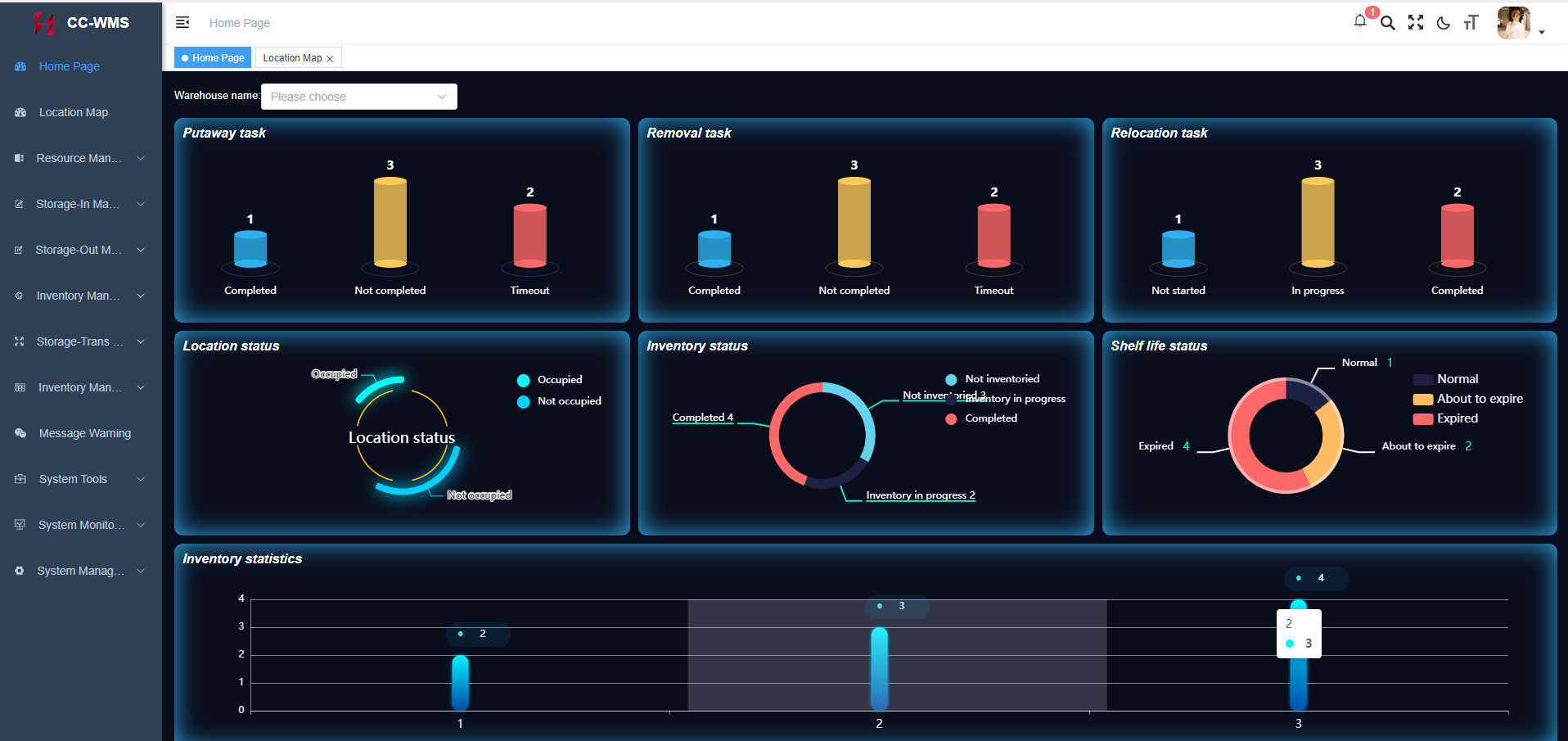

WMS

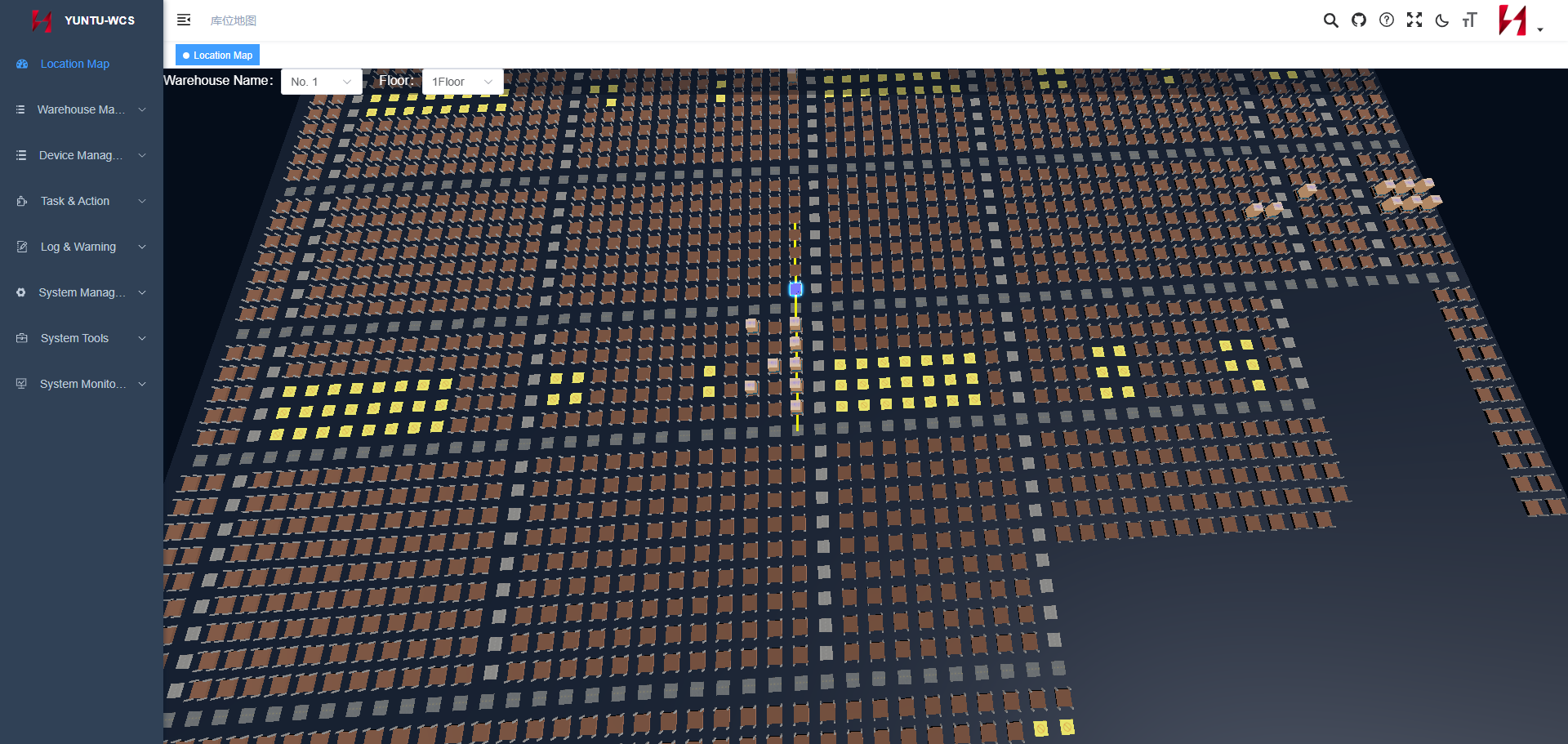

WCS

Modern vertical storage solutions integrate seamlessly with:

lHEGERLS CC-WMS for inventory tracking

lYUNTU-WCS for task scheduling

lAGVs and AMRs for automated inbound/outbound transport

This connectivity forms a closed-loop automation ecosystem.

Enhanced Worker Safety

By eliminating climbing, bending, and reaching, AVSS provides a more ergonomic working environment, reducing workplace injuries and improving employee retention.

Growing Adoption Across Key Industries

E-commerce and Retail Distribution

The rapid growth of SKU variety and fast order turnaround requirements makes vertical storage ideal for:

lSmall-and-medium-size parts

lApparel items

lE-commerce picks

lSpare parts consolidation

Many fulfillment centers now use AVSS as a centralized picking engine.

Manufacturing

Automated Vertical Storage Systems are increasingly used for:

lTooling

lMRO components

lWork-in-process materials

lHeavy or high-value items requiring restricted access

With digital authorization, only approved staff can retrieve sensitive components.

Cold Chain Warehousing

Cold storage is expensive to build and operate. By storing vertically and automating retrieval, AVSS reduces:

lTemperature loss from manual access

lEnergy waste

lHuman exposure to low temperatures

HEGERLS is seeing a rise in AVSS integrations in cold rooms ranging from -40°C to +60°C.

HEGERLS Introduces High-Performance Automated Vertical Storage Technology

With 30 years of experience in warehouse automation, HEGERLS has developed a new generation of Automated Vertical Storage Systems engineered for high-density, high-speed, and highly secure operations.

Key Innovations from HEGERLS Include:

Modular Tower Architecture

Allows facilities to scale from 3 meters to more than 45 meters in height without major structural changes.

High-Speed Lift and Precision Positioning

Optimized for fast order picking, enabling smoother workflows in high-demand warehouses.

Full Digital Visibility

Real-time dashboards show:

lInventory location

lStock levels

lPicking frequency

lSpace utilization efficiency

Seamless Integration with Robotics

Vertical systems can be paired with:

lAMRs/AGVs for transport

lShuttle systems for pallet movement

lConveyor lines for automated order routing

This interoperability creates an end-to-end intelligent warehousing ecosystem.

Demand Drivers for Automated Vertical Storage in 2025

According to market observations and customer engagements, the shift toward vertical automation is driven by:

Space constraints in urban logistics hubs: High rent and limited expansion push companies to exploit cubic storage space.

Rising labor challenges: Workers are harder to recruit and train, and manual picking efficiency is difficult to sustain.

Strategic digital transformation goals: Companies want systems capable of collecting data, predicting needs, and integrating with ERP/WMS platforms.

Expansion of omnichannel fulfillment: Smaller orders with higher frequency require faster and more accurate retrieval systems.

Customer Feedback: What Users Value Most

Across Southeast Asia, Europe, and the Middle East, HEGERLS customers emphasize three core benefits:

Space efficiency: “We increased storage capacity without moving to a new building.”

Picking speed: “Vertical automation helped us handle peak seasons without increasing headcount.”

Stability & reliability: “System uptime above 99% gave us full confidence during high-volume operations.”

The Future of Vertical Automation: A Multi-Layered Smart Warehouse

The industry is moving toward a hybrid warehouse model, where Automated Vertical Storage Systems work side-by-side with:

lFour-way pallet shuttle systems

lBin shuttle systems

lAGVs/AMRs

lRobotic picking arms

lWMS/WCS analytics platforms

This signals a major shift from traditional warehouse layouts toward intelligent, multi-level, autonomous warehousing ecosystems.

Conclusion: Automated Vertical Storage Is Becoming the New Standard

As global supply chains face increased complexity, the adoption of Automated Vertical Storage Systems is accelerating across industries. With advanced lifting technology, digital intelligence, and seamless integration with other automation equipment, AVSS is reshaping how modern warehouses store, retrieve, and manage inventory.

HEGERLS will continue innovating in vertical automation, helping global partners achieve higher efficiency, better space utilization, and stronger operational resilience.

Ready to Upgrade Your Warehouse with Vertical Automation?

Contact HEGERLS today to receive a customized Automated Vertical Storage System proposal tailored to your space, workflow, and storage requirements.

Contact Info

Website: https://www.hegerlsstorage.com/

Email:hegerls1@hegerlsstorage.com

Phone: +86-311-87240955