Why Is ROI Becoming the Key Metric in Warehouse Automation Decisions?

As warehouse automation adoption accelerates globally, investment scrutiny is becoming stricter than ever. Rising interest rates, volatile demand, and tighter capital budgets mean that automation projects are no longer approved on technology appeal alone—they must demonstrate clear and measurable return on investment (ROI).

Industry research shows that over 60% of logistics automation projects are now evaluated primarily on payback period and scalability, rather than maximum throughput alone. This shift places two leading technologies under frequent comparison: four-way pallet shuttle systems and traditional AS/RS solutions.

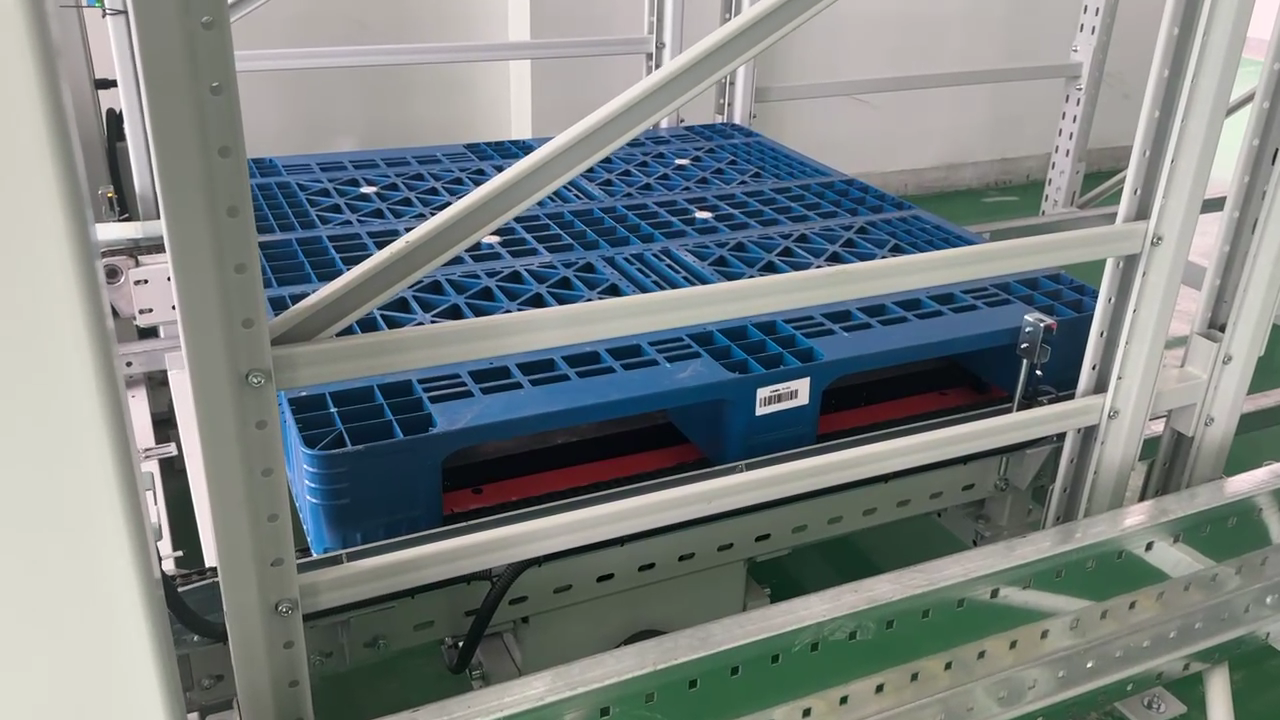

What Is a Four-Way Pallet Shuttle System?

A four-way pallet shuttle system is a high-density automated storage solution where shuttles move pallets in four directions—forward, backward, left, and right—within a racking structure.

Key characteristics include:

l Multi-directional movement within lanes

l Modular and scalable architecture

l Separation of horizontal and vertical movement

l Flexible layout without fixed conveyors

Four-way shuttles are increasingly adopted in cold storage, FMCG distribution, and manufacturing logistics, where space efficiency and adaptability are critical.

What Defines a Traditional AS/RS System?

AS/RS (Automated Storage and Retrieval Systems) typically rely on stacker cranes operating within fixed aisles. Each aisle is usually served by one crane, handling both horizontal and vertical movements.

AS/RS systems are known for:

l High reliability

l Mature engineering standards

l Strong performance in predictable, high-volume environments

They remain widely used in high-bay pallet warehouses and long-term storage facilities.

How Do Four-Way Pallet Shuttles and AS/RS Differ Structurally?

Is System Architecture a Major Cost Driver?

Yes. Structural and mechanical design differences directly influence both CAPEX and OPEX.

l AS/RS requires dedicated aisles and one stacker crane per aisle.

l Four-way pallet shuttle systems allow multiple shuttles to share storage blocks, reducing fixed equipment dependency.

Studies indicate that four-way shuttle systems can reduce initial equipment investment by 15–30% in medium-to-large warehouses, particularly where throughput variability exists.

Which System Uses Space More Efficiently?

Does High-Density Storage Favor Four-Way Shuttles?

Four-way pallet shuttle systems excel in space utilization because they:

l Eliminate fixed aisles

l Enable deeper storage lanes

l Allow flexible zoning

Compared to conventional AS/RS layouts, four-way shuttles typically deliver 30–60% higher storage density, especially in land-constrained or cold storage environments.

AS/RS, while efficient vertically, often sacrifices horizontal density due to aisle requirements.

How Do Throughput Capabilities Compare?

Is AS/RS Still the Throughput Champion?

In extremely high and stable throughput scenarios, AS/RS remains highly competitive. Stacker cranes offer:

l Predictable cycle times

l Continuous operation

l High positioning accuracy

However, four-way pallet shuttle systems close the gap by:

l Adding shuttles to boost capacity

l Dynamically reallocating resources

l Avoiding single-point bottlenecks

In peak-demand environments, operators report up to 40% higher peak throughput flexibility with shuttle-based systems.

How Does Scalability Impact Long-Term ROI?

Why Is Modularity a Financial Advantage?

One of the biggest ROI differentiators lies in scalability.

l AS/RS expansion often requires additional aisles, cranes, and structural changes.

l Four-way pallet shuttle systems scale incrementally—add shuttles, lifts, or software capacity.

This modular growth model aligns investment with business growth, reducing the risk of overcapacity. Financial models show that incremental automation can shorten payback periods by 1–2 years.

What About Maintenance and Operational Costs?

Which System Has Lower OPEX Over Time?

Operational expenses are influenced by:

l Energy consumption

l Maintenance frequency

l Downtime risk

Four-way pallet shuttles benefit from:

l Lighter equipment

l Redundant shuttle architecture

l Easier component replacement

AS/RS stacker cranes, while robust, can become single points of failure if redundancy is not designed properly. Industry data suggests predictive maintenance can reduce downtime for both systems, but shuttle systems generally offer higher operational resilience.

How Do Software Systems Influence ROI?

Is WMS and WCS Integration Equally Important for Both?

Absolutely. Software is often the hidden ROI multiplier.

l A well-implemented WMS improves slotting and inventory accuracy.

l A WCS optimizes equipment coordination and traffic flow.

Four-way pallet shuttle systems rely heavily on intelligent WCS logic to maximize efficiency, while AS/RS benefits from optimized crane scheduling. Warehouses with tightly integrated software report 10–20% efficiency gains regardless of hardware choice.

Which Industries Prefer Four-Way Pallet Shuttles?

Four-way pallet shuttle systems are increasingly favored in:

l Cold storage logistics

l Food & beverage distribution

l E-commerce fulfillment

l Manufacturing buffer storage

These industries value flexibility, density, and future expansion, making shuttle systems a natural fit.

Where Does AS/RS Still Make More Sense?

AS/RS remains a strong option when:

l Throughput demand is stable and predictable

l SKU variety is limited

l Vertical height exceeds 35–40 meters

l Long-term storage dominates operations

In such scenarios, the simplicity and maturity of AS/RS can still deliver strong ROI.

How Should Decision-Makers Choose Between the Two?

What Questions Should Be Asked First?

Before selecting a system, decision-makers should evaluate:

l Expected throughput growth

l SKU diversity

l Land and building constraints

l Expansion plans

l Capital investment strategy

There is no universal answer—the best ROI comes from aligning system design with operational reality.

Conclusion: Which System Delivers Better ROI?

Four-way pallet shuttle systems and traditional AS/RS solutions each have their strengths. However, as warehouse operations become more dynamic, many businesses are discovering that flexibility and scalability are just as valuable as raw throughput.

For operations facing uncertain growth, land constraints, or fluctuating demand, four-way pallet shuttle systems often deliver faster payback and lower long-term risk. AS/RS remains a reliable choice for stable, high-bay environments where predictability outweighs adaptability.

Ultimately, ROI is maximized not by choosing a technology—but by designing the right system for the right application.

Evaluating four-way pallet shuttle or AS/RS for your warehouse?

Consult HEGERLS to compare system ROI, scalability, and automation performance.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-8724095