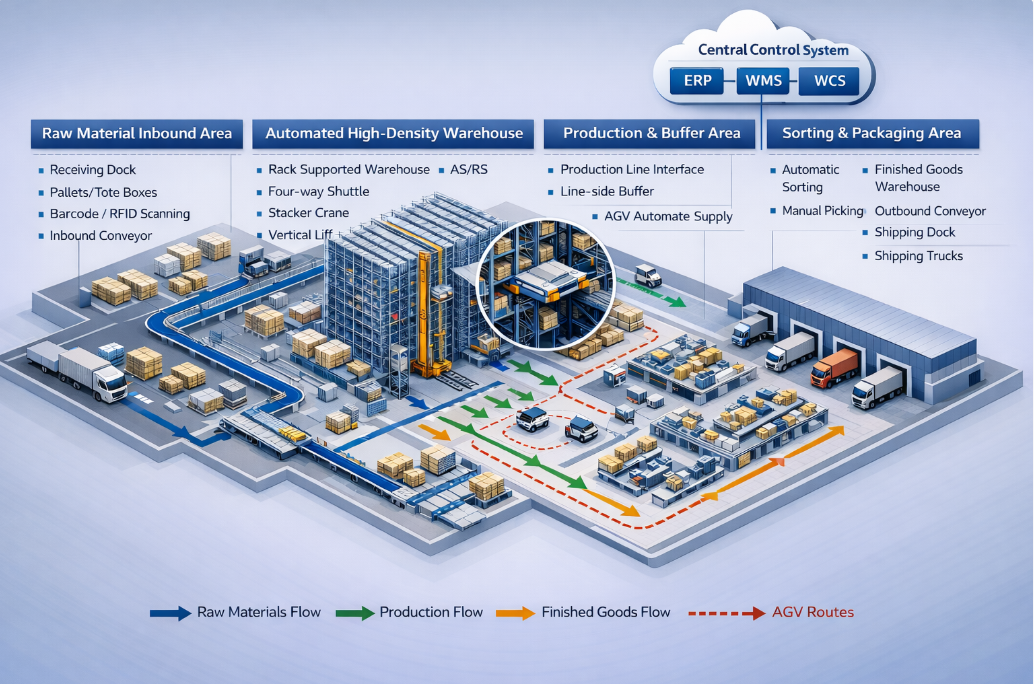

As global manufacturing accelerates toward digitalization and intelligent operations, the concept of the smart factory has evolved far beyond isolated automation upgrades. Today, the true competitiveness of a smart factory lies in system-level integration, data-driven decision-making, and highly efficient internal logistics.

Among all subsystems, intelligent warehousing and intralogistics have become the structural backbone of smart factories, directly impacting production rhythm, space utilization, operational cost, and supply chain responsiveness.

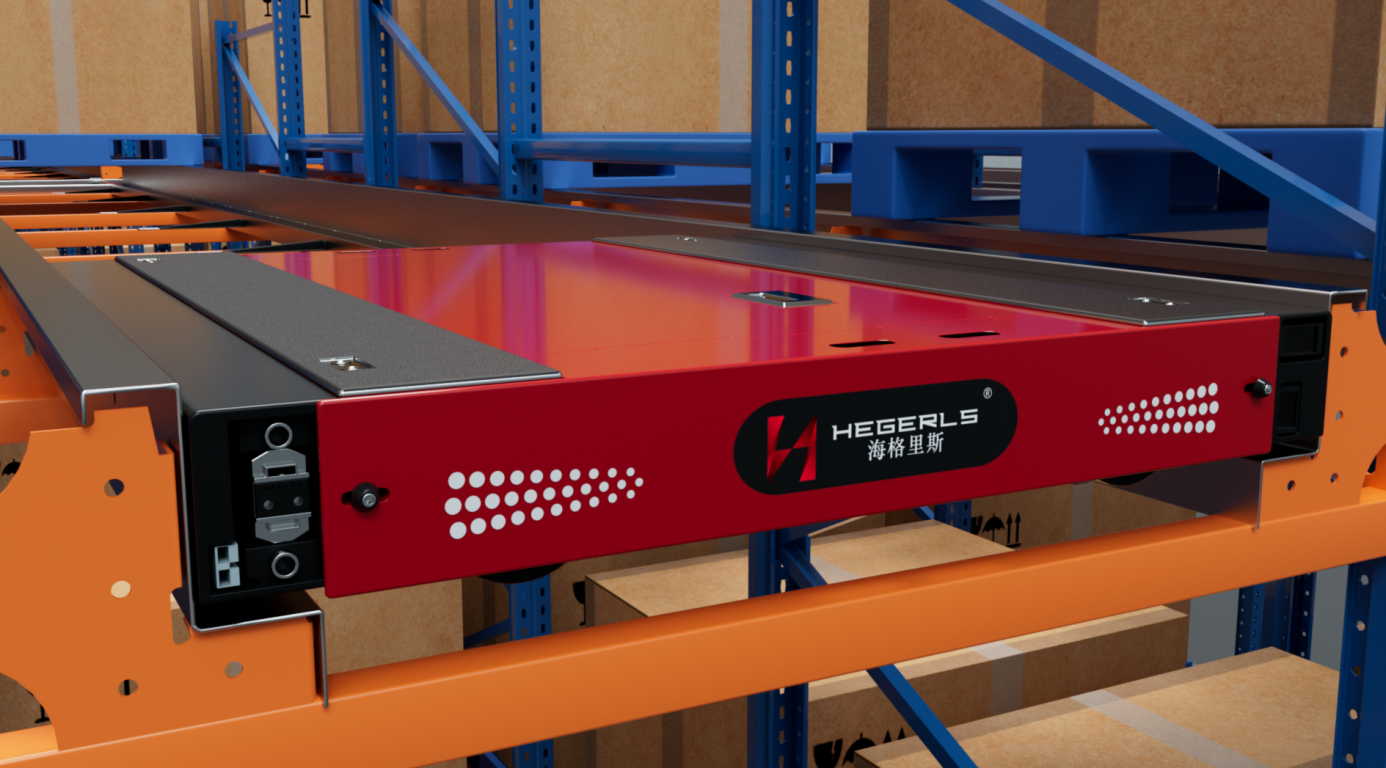

This guide presents a warehouse-centric smart factory planning methodology, integrating advanced technologies such as AI, digital twins, edge computing, industrial networks, and intelligent software systems, with a particular focus on HEGERLS automated warehouse solutions, including rack-supported warehouses, four-way shuttle systems, vertical lifts, and WMS/WCS platforms.

1. Why Intelligent Warehousing Is the Core of Smart Factories

1.1 From Equipment Automation to System Intelligence

Traditional smart factory projects often focus on production equipment—robots, CNC machines, or automated assembly lines—while treating warehousing as a downstream support function. However, real-world project experience shows that production efficiency is ultimately constrained by logistics efficiency.

Common challenges include:

l Bottlenecks caused by delayed material feeding

l Excessive manual handling between workshops and warehouses

l Low space utilization and fragmented inventory

l Poor coordination between production planning and material execution

In contrast, a warehouse-centric smart factory treats storage and material flow as the central nervous system, enabling production to operate smoothly, predictably, and flexibly.

1.2 Intelligent Warehousing as the Core Infrastructure

In HEGERLS smart factory philosophy, the automated warehouse is not just a storage area, but:

l A structural element of the factory (rack-supported warehouse)

l A logistics control hub connecting production, packaging, and shipping

l A data source for planning, optimization, and decision-making

By positioning intelligent warehousing at the center of factory planning, enterprises can unlock long-term scalability and operational resilience.

2. Warehouse-Centric Smart Factory Planning Strategy

2.1 Aligning Business Objectives with Logistics Capabilities

Smart factory planning must start with clear business goals, such as:

l Increasing output without expanding land or buildings

l Reducing labor dependency and operating costs

l Supporting high-mix, low-volume, or customized production

l Ensuring safety and reliability in cold storage or chemical environments

Automated warehousing solutions—especially high-density rack-supported systems combined with shuttle technology—are uniquely suited to address these objectives.

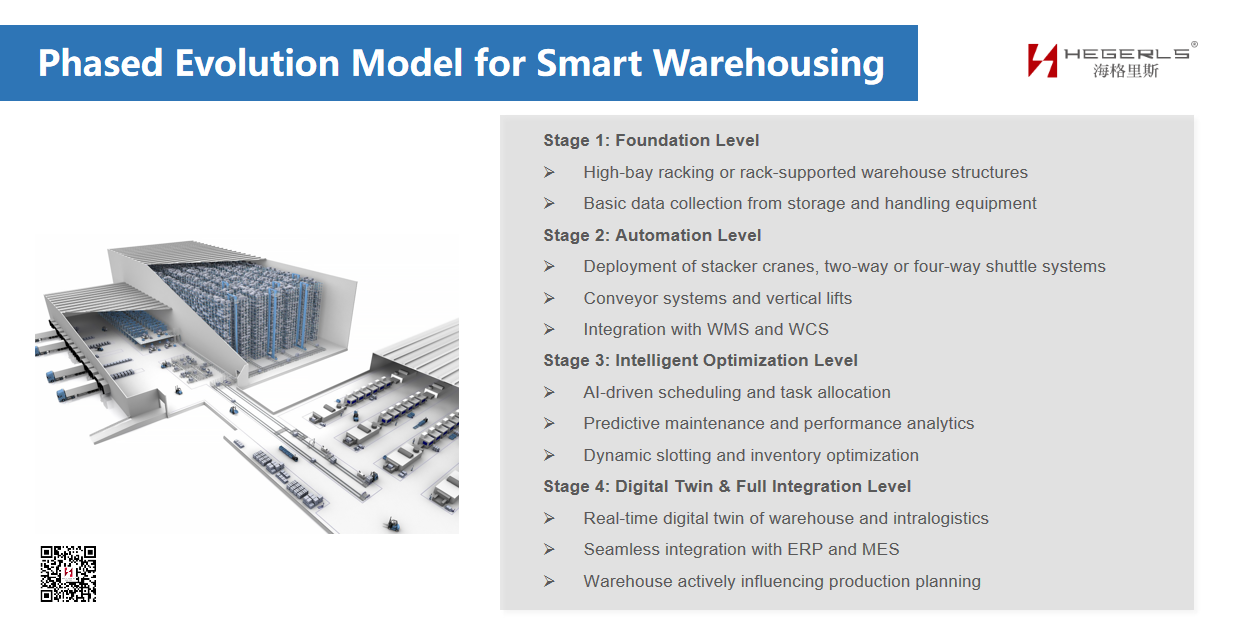

2.2 Phased Evolution Model for Smart Warehousing

HEGERLS recommends a step-by-step maturity path, aligned with global smart manufacturing standards:

Stage 1: Foundation Level

l High-bay racking or rack-supported warehouse structures

l Basic data collection from storage and handling equipment

Stage 2: Automation Level

l Deployment of stacker cranes, two-way or four-way shuttle systems

l Conveyor systems and vertical lifts

l Integration with WMS and WCS

Stage 3: Intelligent Optimization Level

l AI-driven scheduling and task allocation

l Predictive maintenance and performance analytics

l Dynamic slotting and inventory optimization

Stage 4: Digital Twin & Full Integration Level

l Real-time digital twin of warehouse and intralogistics

l Seamless integration with ERP and MES

l Warehouse actively influencing production planning

This phased approach ensures controlled investment, manageable risk, and continuous value creation.

2.3 Defining Measurable Performance Indicators

To ensure success, warehouse-centric smart factories must be evaluated through clear KPIs, including:

l Space utilization rate

l Throughput capacity (pallets/hour or bins/hour)

l Order picking and feeding accuracy

l Labor reduction ratio

l Equipment availability and MTBF

l Energy consumption per unit handled

These indicators guide both system design and long-term optimization.

3. Advanced Technologies Applied to Smart Warehousing

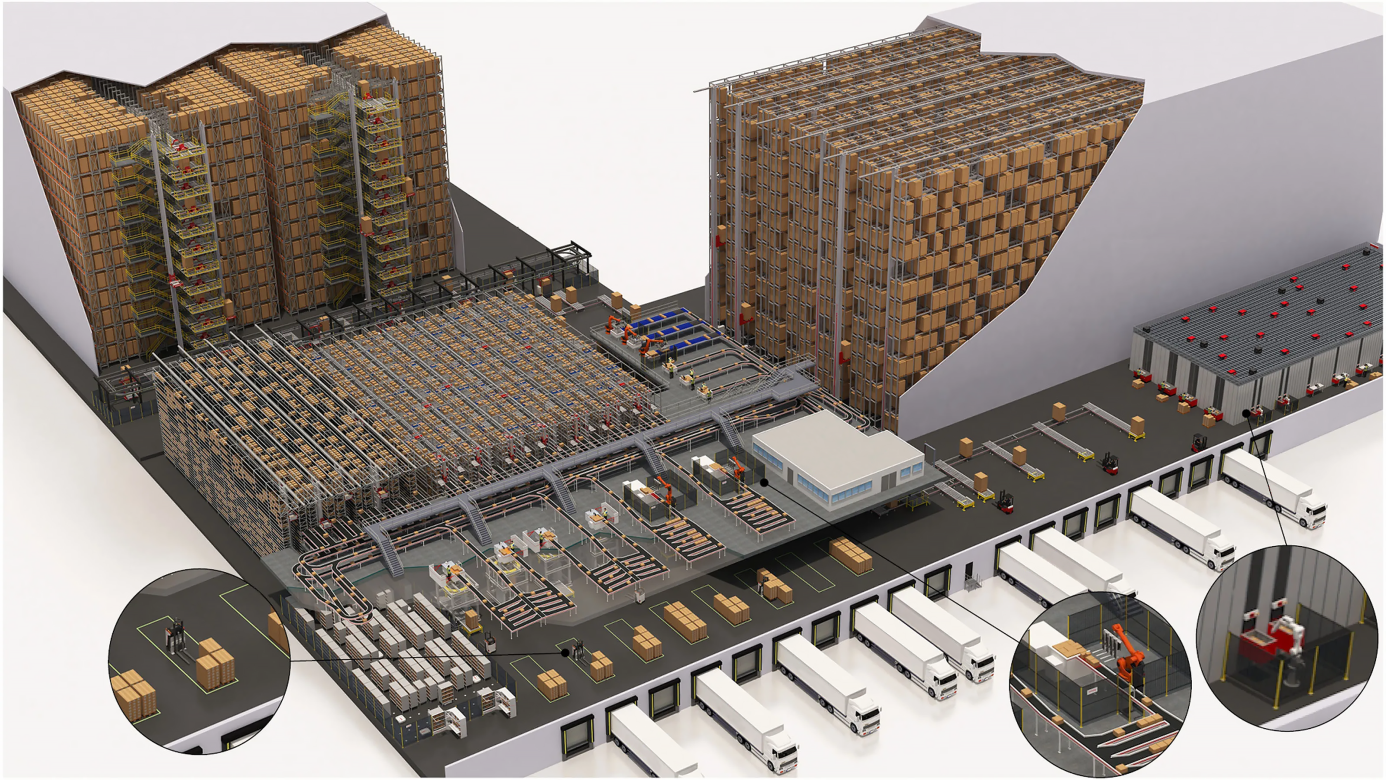

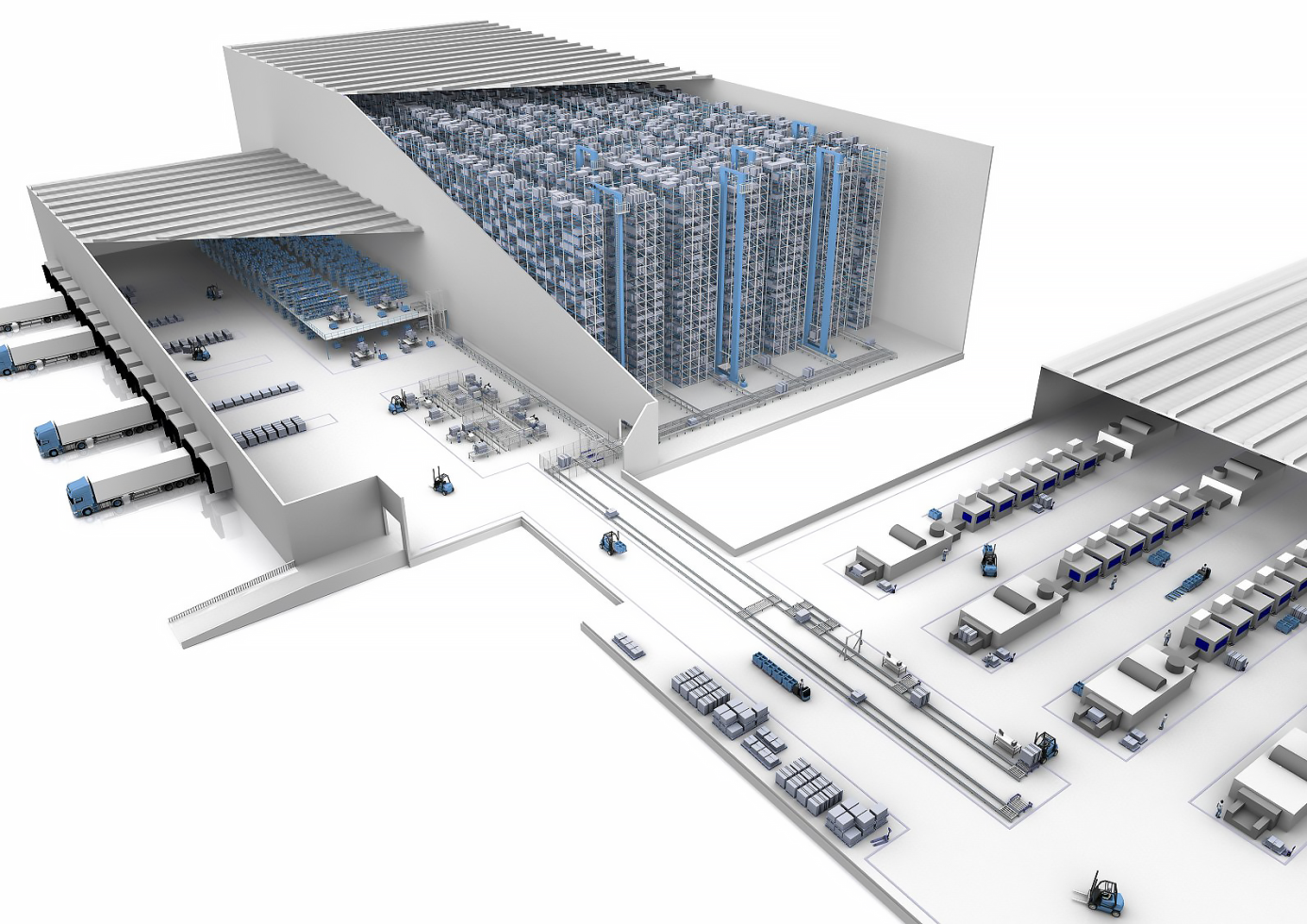

3.1 Rack-Supported Warehouse Systems for Smart Manufacturing

HEGERLS rack-supported warehouse systems integrate building structure and storage racking into a single load-bearing unit. This approach offers:

l Maximum vertical space utilization

l Shorter construction cycles

l Reduced building material costs

l High structural stability for automated equipment

Such systems are ideal for manufacturing plants requiring large-scale, high-density storage closely integrated with production lines.

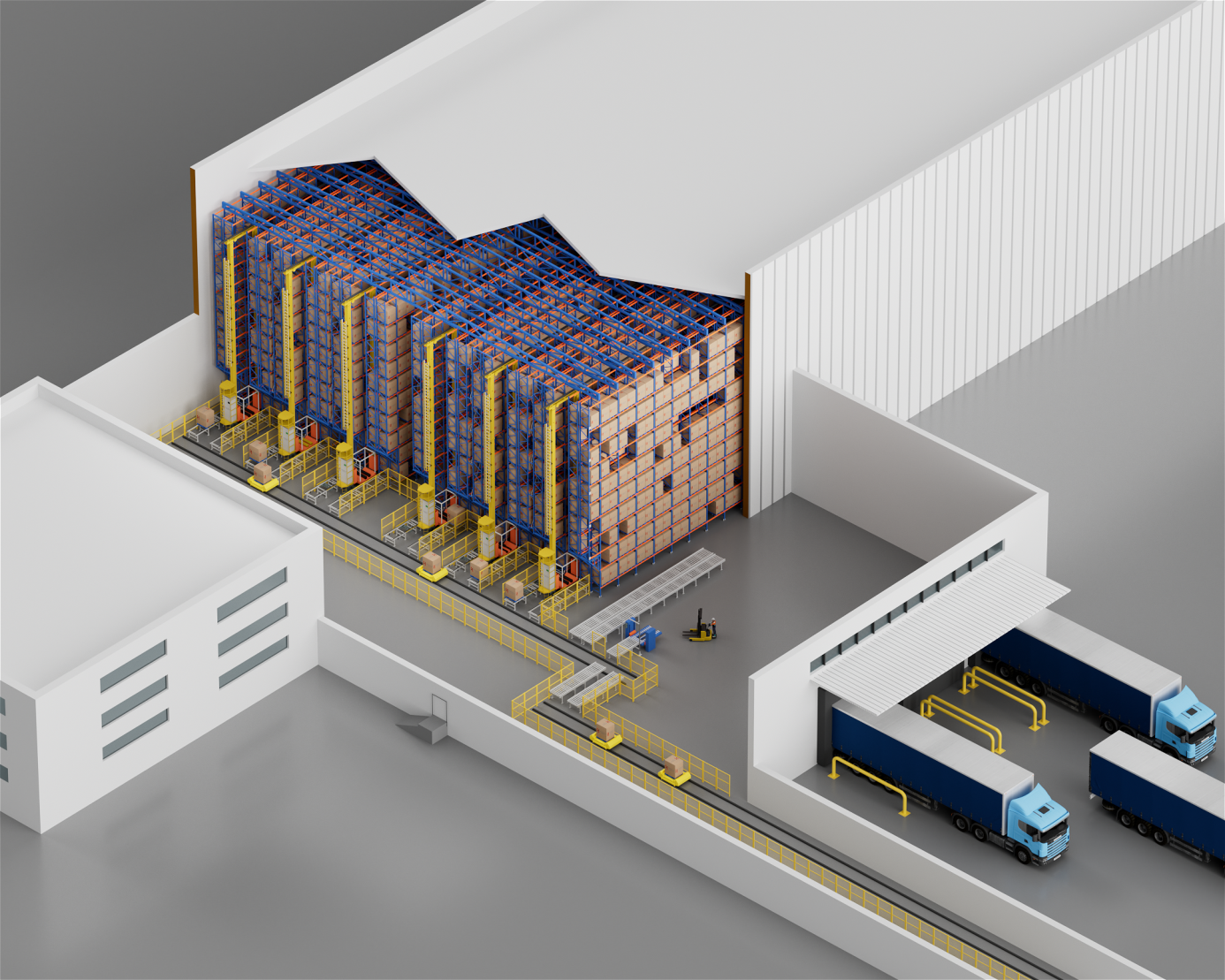

3.2 Four-Way Shuttle and Automated Intralogistics Solutions

Depending on operational requirements, HEGERLS provides flexible combinations of:

l Four-way shuttle systems for ultra-high-density, multi-channel storage

l Two-way shuttle systems for cost-effective automated storage

l Vertical lifts and conveyors connecting multiple floors and zones

Advanced control algorithms enable:

l Parallel task execution

l Dynamic route optimization

l Load balancing across multiple shuttles

This ensures high throughput even during peak production cycles.

3.3 Digital Twin Technology for Warehouse Simulation

Digital twin technology transforms warehouse planning and operation by creating a real-time virtual replica of the physical system.

Applications include:

l Simulation of layout and throughput before implementation

l Stress-testing peak demand scenarios

l Continuous optimization of shuttle routes and buffer zones

l Rapid troubleshooting and scenario analysis

By linking digital twins with live operational data, HEGERLS enables data-driven decision-making throughout the warehouse lifecycle.

3.4 AI and Big Data: From Execution to Optimization

Artificial intelligence elevates warehouse systems from automation to intelligence.

Key applications include:

l AI-based task scheduling, dynamically allocating shuttle and lift resources

l Predictive maintenance, identifying potential failures before downtime occurs

l Inventory intelligence, optimizing slotting based on demand patterns

l Energy optimization, reducing unnecessary movements and idle time

As data accumulates, warehouse systems continuously improve performance without structural changes.

3.5 Edge–Cloud Architecture for Real-Time Control

HEGERLS smart warehouses adopt a “Device–Network–Edge–Cloud” architecture:

l Devices: Shuttles, lifts, sensors, conveyors

l Network: Industrial Ethernet or private 5G

l Edge computing: Real-time control and safety logic

l Cloud platforms: Data analytics, optimization, visualization

This architecture ensures low latency, high reliability, and scalability, even in high-throughput environments.

3.6 Safety, Sustainability, and Special Environments

Smart factories must operate safely and sustainably, especially in demanding environments such as cold storage or chemical facilities.

HEGERLS integrates:

l Collision avoidance and redundant safety mechanisms

l Fire detection and monitoring systems

l Anti-corrosion coatings and low-temperature-resistant designs

l Energy monitoring and carbon footprint tracking

These measures support long-term, compliant, and environmentally responsible operations.

4. Implementation Roadmap for Smart Factory Warehousing

4.1 Pre-Project Assessment and Diagnostics

Successful projects begin with a comprehensive evaluation of:

l Existing warehouse and production layouts

l Material flow inefficiencies

l Data availability and system readiness

l Future expansion requirements

This ensures that technology selection aligns with real operational needs.

4.2 Pilot Projects and Incremental Deployment

Rather than full-scale transformation at once, HEGERLS recommends:

l Starting with a core warehouse or key material flow

l Establishing a standardized, replicable solution

l Gradually extending automation and intelligence

This minimizes disruption and accelerates return on investment.

4.3 Long-Term Evolution and Ecosystem Integration

As systems mature, intelligent warehouses begin to:

l Actively influence production scheduling

l Provide real-time feedback to ERP and MES

l Support supply chain collaboration and transparency

Ultimately, the warehouse evolves from a cost center into a strategic asset within the smart factory ecosystem.

5. Core Philosophy: Technology Must Serve Value Creation

The essence of smart factory construction is not technological complexity, but practical value creation.

For HEGERLS, advanced technologies are meaningful only when they:

l Increase space efficiency

l Improve logistics speed and reliability

l Reduce operational risk and cost

l Enable sustainable, long-term growth

By combining robust physical systems, intelligent software, and advanced digital technologies, HEGERLS helps manufacturers build smart factories that are not only automated—but truly intelligent, resilient, and future-ready.

Conclusion

Smart factories begin with smart warehousing.

By placing intelligent storage and intralogistics at the core of factory planning—and empowering them with AI, digital twins, and integrated software — manufacturers can achieve a new level of operational excellence. HEGERLS remains committed to delivering warehouse-centric smart factory solutions, helping global manufacturers transform logistics challenges into lasting competitive advantages.

Start Your Smart Factory Warehouse Project

Looking to build a smart factory with intelligent warehouse automation?

Contact HEGERLS to design a rack-supported warehouse and intralogistics system tailored to your production needs.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955