Why Are Warehouse Automation Solutions Becoming Essential Worldwide?

Global supply chains are under unprecedented pressure. Rising labor costs, shrinking warehouse footprints, increasing SKU complexity, and customer expectations for faster delivery are forcing warehouses to rethink traditional storage and handling models.

According to Fortune Business Insights, the global warehouse automation market exceeded USD 21 billion in 2024 and is projected to grow at over 15% CAGR through 2030. Automation is no longer a competitive advantage—it is becoming a baseline requirement.

Warehouse automation solutions integrate intelligent storage systems, robotics, software platforms, and data-driven control technologies to improve throughput, accuracy, and space utilization while reducing operational risk.

What Are Warehouse Automation Solutions?

Warehouse automation solutions refer to a holistic system that automates material storage, movement, picking, and management processes using a combination of:

l Automated storage and retrieval systems (AS/RS)

l Shuttle-based high-density storage

l Smart racking structures

l Warehouse Management Systems (WMS)

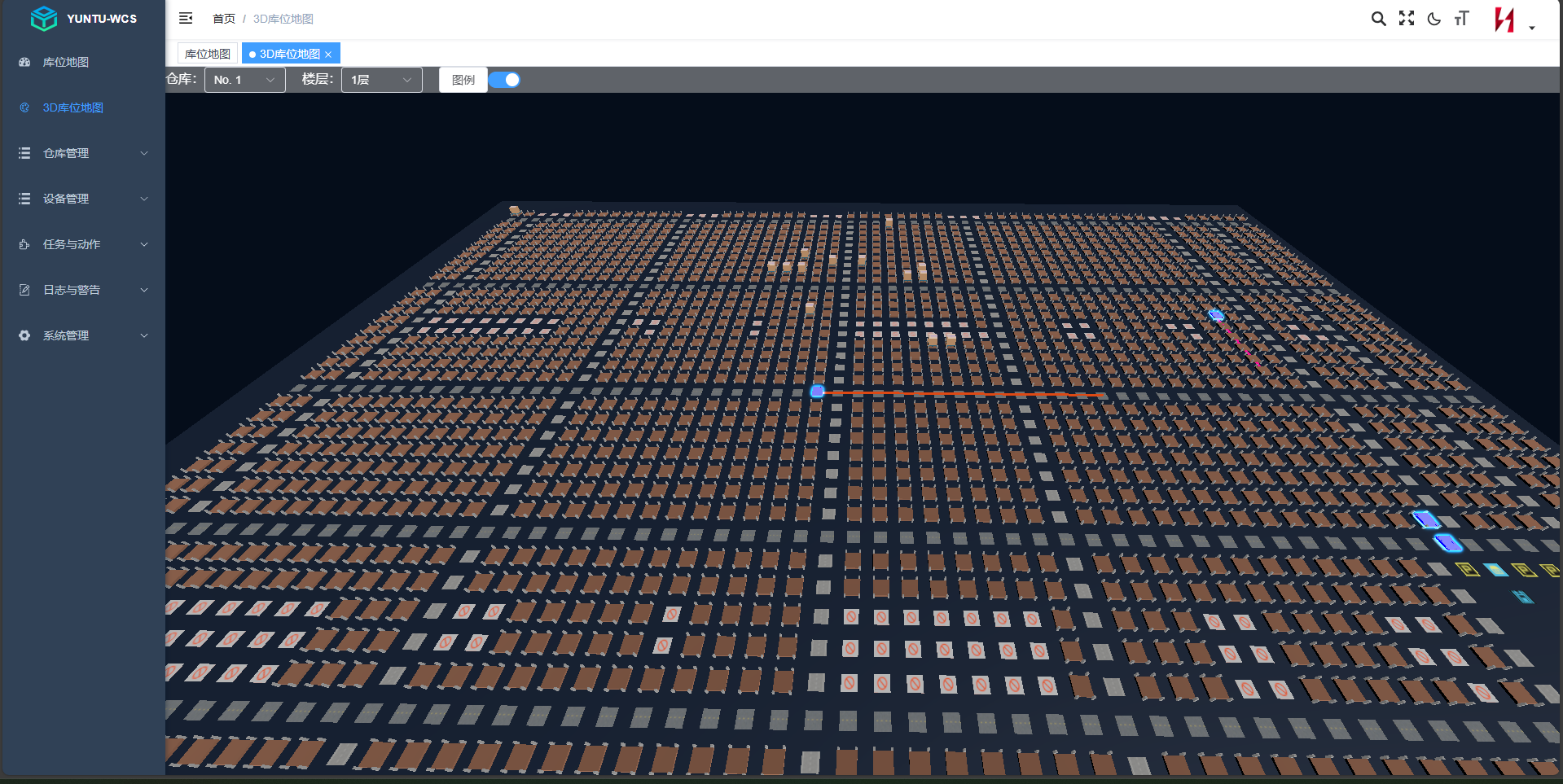

l Warehouse Control Systems (WCS)

l Robotics and intelligent conveying

Rather than isolated machines, modern automation focuses on system-level optimization, where hardware and software operate as a coordinated ecosystem.

Which Storage Systems Form the Foundation of Automated Warehouses?

Is High-Density Storage the Core of Automation Strategy?

High-density storage solutions are the backbone of most automated warehouses, particularly in industries with limited land availability.

Studies show that high-density storage can increase space utilization by 30–60% compared to conventional selective racking. Technologies commonly used include:

l Four-way pallet shuttle systems

l Automated shuttle systems

l Mobile racking

l Deep-lane storage

For cold storage and urban logistics, high-density automation is often the only viable option.

When Does Rack Supported Warehouse Design Make Sense?

A rack supported warehouse (also known as a clad-rack warehouse) integrates the racking structure as part of the building’s load-bearing system.

This design is ideal when:

l Land costs are high

l Building height exceeds 25 meters

l Seismic and wind loads must be optimized

Industry data indicates that rack-supported warehouses can reduce total construction costs by up to 20% while shortening project timelines.

How Do Shuttle Systems Transform Warehouse Efficiency?

Why Are Four-Way Shuttle Systems Becoming an Industry Standard?

Four-way shuttle systems enable pallets to move in both longitudinal and transverse directions, eliminating the need for fixed conveyors or aisle-specific equipment.

Key advantages include:

l Flexible layout design

l Scalability by adding shuttles

l High throughput under peak demand

In high-volume distribution centers, four-way shuttle systems have been shown to increase throughput by 40–50% compared to traditional AS/RS.

How Do Automated Shuttle Systems Support Future Expansion?

Unlike fixed automation, shuttle systems are modular. Warehouses can start with a small number of shuttles and expand capacity gradually, aligning investment with business growth.

This flexibility significantly reduces upfront capital risk—one of the major barriers to automation adoption identified by CFO Dive in recent industry research.

What Role Do Stacker Cranes Play in Automated Warehousing?

Stacker crane systems remain a cornerstone of automated pallet handling, especially in high-bay warehouses.

Modern stacker cranes offer:

l Lifting heights over 40 meters

l High positioning accuracy (±2 mm)

l Energy-efficient regenerative braking

Market analysts estimate the stacker crane market will surpass USD 1.5 billion by 2030, driven by demand in cold storage, manufacturing, and spare parts logistics.

How Do Smart Racking Systems Improve Warehouse Performance?

Smart racking goes beyond steel structures. Embedded sensors, load monitoring, and system connectivity allow racks to interact with control software.

Benefits include:

l Real-time load monitoring

l Structural safety alerts

l Seamless integration with WMS/WCS

This evolution aligns with Industry 4.0 principles, transforming static storage into intelligent infrastructure.

Why Is Software the Brain of Warehouse Automation Solutions?

What Does a Warehouse Management System (WMS) Control?

A WMS manages inventory logic, location assignment, order prioritization, and data analytics.

Modern WMS platforms can:

l Improve picking accuracy to 99.9%

l Reduce inventory discrepancies by up to 35%

l Enable real-time visibility across multiple facilities

How Does a Warehouse Control System (WCS) Optimize Equipment?

A WCS operates at the execution layer, coordinating shuttles, cranes, conveyors, and robotics in real time.

When WMS and WCS are tightly integrated, warehouses achieve:

l Smoother equipment synchronization

l Reduced downtime

l Predictive maintenance capabilities

How Is Predictive Maintenance Improving Automation Reliability?

Predictive maintenance uses sensor data, historical performance, and AI algorithms to anticipate failures before they occur.

According to McKinsey, predictive maintenance can:

l Reduce equipment downtime by 30–50%

l Extend asset life by 20–40%

l Lower maintenance costs by up to 25%

For automated warehouses operating 24/7, uptime is directly tied to revenue.

What Role Do Warehouse Robotics Play Today?

Warehouse robotics—such as AMRs, pallet shuttles, and robotic handling systems—are increasingly adopted to address labor shortages.

However, successful deployment depends on system integration, not robot quantity. Practical automation focuses on stability, safety, and ROI rather than novelty.

How Do Automation Solutions Address Cold Storage Challenges?

Cold storage automation is one of the fastest-growing segments. Operating at temperatures as low as -25°C, automated systems eliminate human exposure to harsh environments.

The global cold storage market is projected to exceed USD 500 billion by 2032, making automation a strategic necessity rather than an option.

What Should Businesses Consider Before Investing in Automation?

Key evaluation criteria include:

l Throughput requirements

l SKU characteristics

l Expansion flexibility

l Software compatibility

l Total lifecycle cost

Automation success is driven by system design expertise, not just equipment selection.

What Are the Future Trends in Warehouse Automation Solutions?

Looking ahead, automation will continue to evolve toward:

l Greater system modularity

l AI-driven optimization

l Deeper software integration

l Lower entry barriers for mid-sized warehouses

Warehouses that invest today are positioning themselves for resilience in an increasingly volatile global supply chain.

Conclusion: Why Warehouse Automation Is a Strategic Investment

Warehouse automation solutions are no longer isolated technologies—they are integrated systems shaping the future of global logistics. From high-density storage and rack supported warehouse design to shuttle systems, smart racking, and intelligent software, automation delivers measurable gains in efficiency, safety, and scalability.

For companies aiming to remain competitive, automation is not a question of if, but how and when.

Looking to design an efficient warehouse automation solution?

Talk to HEGERLS experts about system design, scalability, and ROI.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955