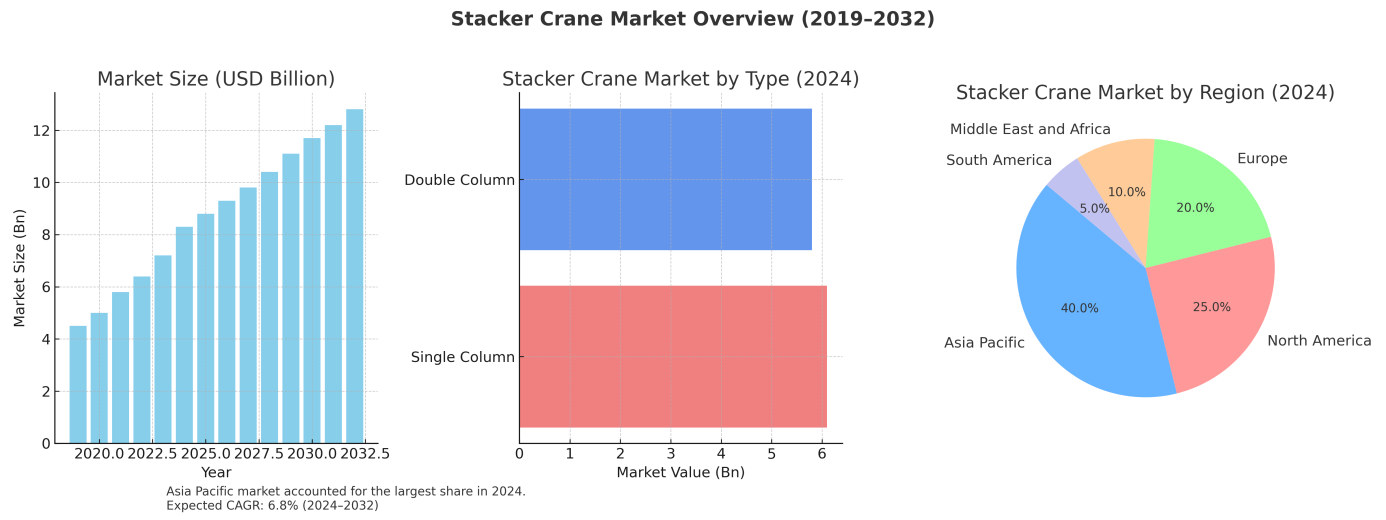

[Hebei, China – October 2025] As warehouse automation continues to accelerate worldwide, the market for high-rise automated storage & retrieval systems is drawing strong attention. According to the recent report by Maximize Market Research, the global stacker crane market was estimated at approximately USD 1.19 billion in 2024, and is expected to grow at a CAGR of about 6.8% to reach around USD 2.01 billion by 2032.

For HEGERLS, this trend affirms the strategic importance of our Stacker Crane System and the compelling value proposition we bring to clients seeking high-density, high-speed, and automated storage solutions.

Stacker Crane Market Highlights

Market size in 2024: ~ USD 1.19 billion.

Forecast period: 2025 to 2032 with CAGR ~6.8%.

Growth segments include automatic operation types, double-column systems, end-uses in e-commerce, retail & wholesale, pharmaceuticals, automotive.

Geographically, Asia-Pacific continues to dominate in adoption and manufacturing, with strong growth in China, India, Southeast Asia.

Market Drivers & Insights

Space constraints: With land and warehouse space becoming more costly in many regions, vertical storage gains urgency. Stacker cranes allow high-rise racking, making better use of cubic meters rather than just floor area.

Demand for throughput: E-commerce, manufacturing spare-parts logistics, cold-chain fulfilment all demand faster retrieval, higher availability, and lower error rates. Stacker cranes support these demands.

Labor / safety pressure: Fewer manual forklift movements in narrow aisles, fewer human errors, improved safety and controlled environment.

Automation integration: Stackers are increasingly integrated with WMS/WCS, robotics,conveyors — forming part of a larger smart warehouse ecosystem.

Emerging regions: Growth in Asia-Pacific, India, Southeast Asia, and Latin America is driving investments in modern warehouse infrastructure, including stacker crane systems.

Product Focus: HEGERLS Stacker Crane System

Our automated stacker crane systems provide a complete solution for high-density storage environments, combining advanced robotics with intelligent software to create efficient, reliable, and scalable warehouse operations. Utilize vertical space efficiently with storage heights up to 40 meters, increasing storage capacity by up to 80 % compared to traditional warehousing.

Key Specifications & Features

Pallet Rail Stacker Crane: Supports pallet sizes 500×500 up to 1300×1300 mm, loads up to 2,000 kg, structure heights to 40 m, travel speeds up to 180 m/min and lifting speeds up to 60 m/min.

Miniload Stacker Crane: For bins/cartons/totes (200×200 mm to 650×650 mm), loads 5–100 kg, travel speeds up to 240 m/min — ideal for e-commerce, pharmaceuticals, electronics.

Over 18 safety functions including emergency stop, overload protection, rope-break protection.

Compatible with ambient, cold or even freezer storage conditions (down to –40°C) for deep-freeze cold chain.

Full integration: high-rise racking, stacker cranes, conveyors, warehouse control & management systems.

Benefits to Clients

Storage Density: By moving vertically and using narrow-aisle profiles, clients can increase capacity ~80% versus conventional warehousing.

Speed & Accuracy: High travel & lift speeds reduce handling time; robotics pick/put reduce errors; software-managed flows improve reliability.

Labor & Safety Gains: Operators stay out of narrow, high-elevation aisles; risk reduced; workforce more focused on value tasks.

Flexibility: Single or double column, pallet or miniload variants, customization for load size, height, environment.

Cold-Chain Ready: Ability to function reliably in harsh environments (sub-zero) differentiates for food, pharma, freezer operations.

HEGERLS Strategic Response & Product Alignment

Given the market dynamics, HEGERLS is positioning itself to meet client demands via product features, software integration, service models and regional focus:

Product Strengths

HEGERLS Stacker Crane System aligns directly with market needs:

Enables high-rise storage and retrieval, tapping vertical space efficiency.

Designed for automation readiness and precision operation.

Customisable to client layout, throughput and load profiles.

Compatible with other HEGERLS systems (shuttles, racking, mobile racking) for integrated warehousing solutions./product-four-way-shuttle-system.html.

Shuttles

Mobile Racking

Software & Control Integration

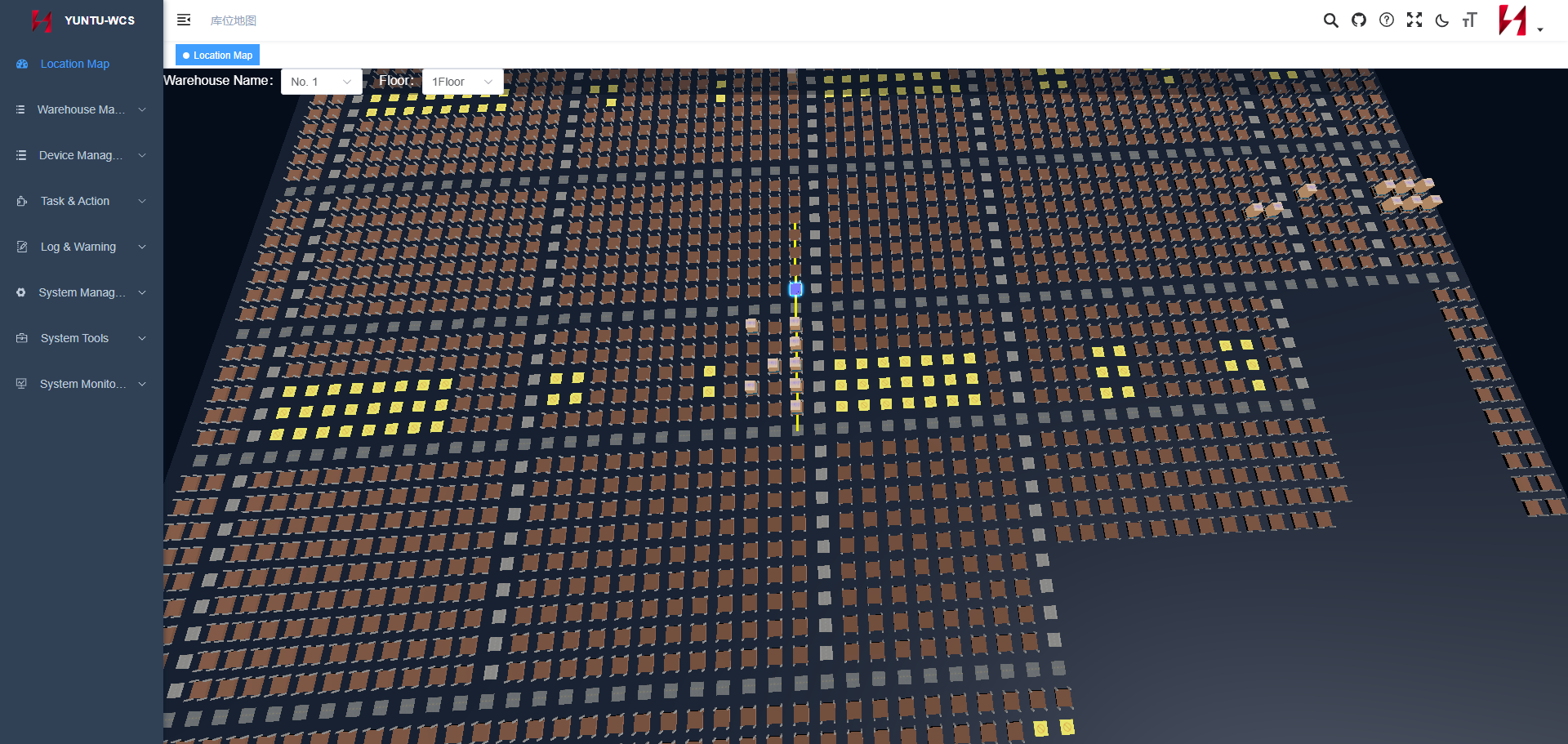

HEGERLS’ software ecosystem (such as CC-WMS and YUNTU-WCS) gives control over stacker crane operations, including:

CC-WMS

YUNTU-WCS

Task scheduling and throughput optimisation.

Real-time monitoring of crane status, maintenance alerts.

Integration with broader warehouse systems (racking, shuttles, storage zones).

This integration helps reduce lifecycle cost, increase uptime, improve ROI for clients.

Adoption Strategy

Modular deployment: Clients can start with core stacker crane lanes and expand into full automated storage as demands increase.

Retrofit friendly: For warehouses upgrading existing layouts, HEGERLS systems aim to integrate with minimal disruption.

Service & support: Establish strong after-sales maintenance, spare parts, diagnostics support — critical given high cost and complexity of stacker systems.

Regional & Segment Focus

Target growth in Asia-Pacific (China, India, SE Asia) where manufacturing growth + e-commerce expansion = high demand.

Focus on sectors: e-commerce fulfilment, pharmaceuticals (cold chain or precision parts), heavy equipment/spare parts warehousing.

Emphasise markets where land/space is constrained => vertical storage (stacker crane) becomes a competitive advantage.

Market Need Meets the HEGERLS Offering

Market Need | HEGERLS Solution |

Growing demand for high-rise automated storage | Stacker Crane System supports up to 40 m heights, 2,000 kg loads, rapid movement |

Need for integrated automation (hardware + software) | HEGERLS system includes full stack: racking, stacker crane, conveyors, WMS/WCS integration |

Cost per storage unit and ROI concerns | Higher density means lower land/rack cost per pallet; faster retrieval improves throughput and return |

Diverse application sectors (e-commerce, pharma, cold chain) | Miniload variant + cold-ready design expands sectors; customisation allows industry-specific tuning |

Emerging markets with space & labour constraints | Modular system, retrofit friendly, scalable investment, suitable for Asia-Pacific, India, SE Asia |

Unique HEGERLS Insights

Here are some original viewpoints from HEGERLS’s vantage:

“Vertical and Modular” Thinking Wins

Rather than expanding warehouse footprint outward, the future is upward and modular. Systems that allow “start small, grow tall” let operators match CAPEX to growth. HEGERLS’s stacker cranes support this evolution.

Software Makes the Difference

Many stacker crane systems exist, but the real value is the orchestration: how the system integrates with WMS/WCS, how it monitors usage, how it drives maintenance, how it optimises throughput. HEGERLS emphasises both hardware and software.

Sustainability Advantage

A high-rise automated storage system reduces energy needed for lighting/forklift traffic, improves thermal envelope usage (especially in cold chain), and supports ESG goals. Clients will increasingly evaluate stacker crane investments on energy per pallet move, not just speed.

Hybrid Storage Ecosystems

Not all SKUs need full stacker crane treatment. The warehouse of the future will combine stacker crane lanes (for core high-density, slow-moving items), shuttle systems (for mid-velocity), and manual/pick zones. HEGERLS supports this layered strategy.

Service & Lifecycle Matters

Because stacker crane systems are expensive and complex, the supplier’s service, spare parts, remote diagnostics, maintenance programmes become as important as the initial specification. HEGERLS emphasises full lifecycle support.

Why This Matters for Clients & Warehousing Ecosystems

For warehouse operators, logistics service providers, manufacturing firms, and 3PLs, the growing stacker crane market indicates that high-rise automated retrieval systems are no longer niche—they’re becoming mainstream. Key client benefits include:

Increased storage density — reducing land/floor area cost.

Improved throughput and retrieval speed — critical for e-commerce and just-in-time operations.

Better labour utilisation and safety — less manual forklift work, fewer accidents.

Lower lifetime cost if integrated efficiently with software and other automation systems.

By choosing HEGERLS, clients gain a partner that provides both hardware (stacker crane, racking, shuttles) and software/control layers — enabling a smoother path to automation, better ROI, and future flexibility.

Recommendations for Warehouse Operators

Perform a density audit: Evaluate current space-use and consider how much vertical storage you’re leaving unused.

Define automation phasing: Consider deploying stacker crane lanes gradually, starting with the most constrained/bottleneck aisles.

Specify integration readiness: Ensure any stacker crane system supports your WMS/WCS and data infrastructure.

Look beyond initial cost: Evaluate total cost of ownership—including energy, maintenance, throughput improvement, footprint savings.

Choose a partner not just a supplier: Make sure you get full project lifecycle support (design, manufacture, install, service).

Conclusion

The stacker crane market is growing strongly—driven by space constraints, automation demands, and evolving logistics needs. HEGERLS Stacker Crane System, with its high performance, customization, integration readiness and industry focus, is positioned to support clients in realizing that growth efficiently and strategically.

If you are planning to upgrade your warehouse, optimize your storage density, or transition to a new automation strategy, HEGERLS invites you to explore how our stacker crane system can be tailored to your gear, layout, throughput and sector needs.

Contact HEGERLS today to discover more, request a quote, or schedule a project consultation.