In the era of rapid digital transformation, warehouses and distribution centers face growing demands for speed, accuracy, and operational efficiency. Businesses across industries are seeking intelligent solutions to optimize inventory management, reduce manual labor, and improve throughput. HEGERLS, a global leader in smart warehouse solutions, is at the forefront of this transformation, offering warehouses that integrate Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) to deliver seamless, data-driven automation.

By combining advanced automation technologies with sophisticated software systems, HEGERLS enables companies to streamline their operations, achieve higher accuracy, and scale efficiently, meeting the dynamic demands of modern supply chains.

The Power of WMS & WCS Integration

Traditional warehouses often struggle with inefficiencies due to disconnected systems. WMS and WCS serve different but complementary functions:

l WMS focuses on inventory management, order processing, and overall workflow planning.

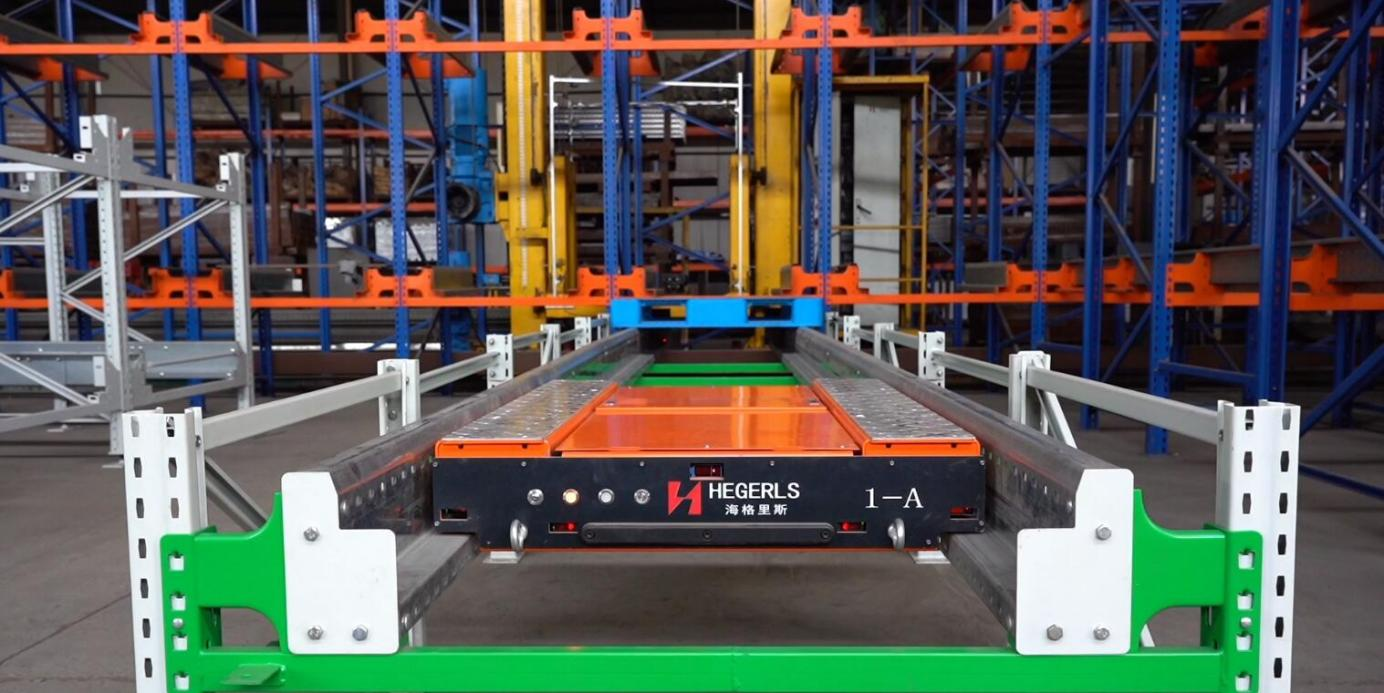

l WCS directly controls warehouse equipment such as conveyors, shuttle systems, automated storage and retrieval systems (ASRS), and robotic units.

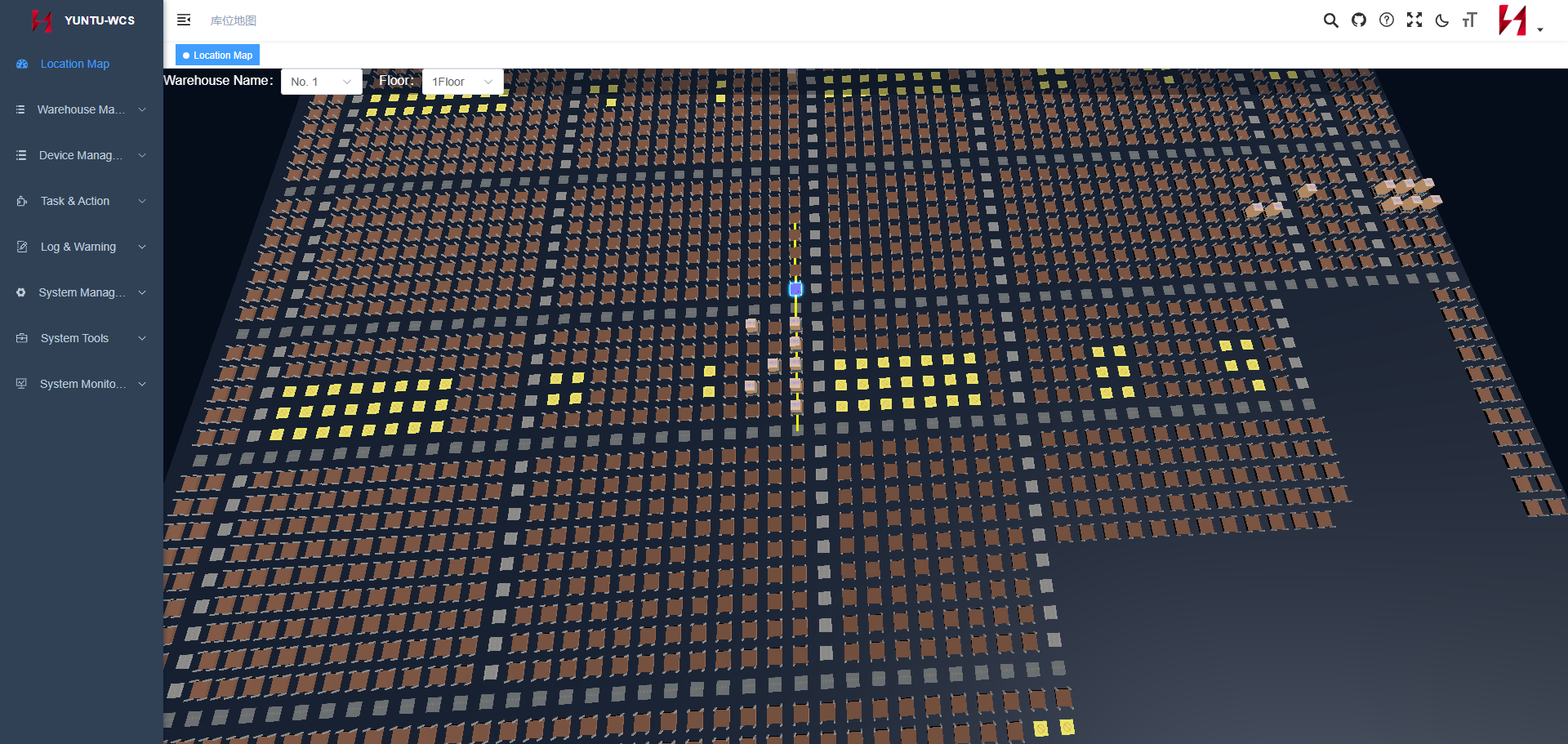

When integrated, these systems provide real-time visibility, precise control, and seamless coordination. HEGERLS smart warehouses leverage this integration to ensure that every piece of equipment operates in sync with inventory data, orders, and workflow priorities, reducing errors and maximizing throughput.

Enhancing Operational Efficiency

One of the key benefits of HEGERLS WMS & WCS integration is dramatically improved operational efficiency.

l Automated Material Handling: Our warehouses can manage multiple four-way shuttle systems and ASRS units simultaneously, enabling continuous storage and retrieval without downtime.

l Faster Order Fulfillment: Orders are processed faster with intelligent task scheduling, which prioritizes urgent orders and dynamically adjusts equipment operations.

l Reduced Manual Labor: By automating repetitive and labor-intensive tasks, HEGERLS reduces human error and allows staff to focus on higher-value activities.

For example, a modern e-commerce fulfillment center equipped with HEGERLS integrated system can process thousands of orders daily, with automated shuttles moving goods efficiently between racks, conveyor systems, and packing stations.

Real-Time Data for Smarter Decisions

HEGERLS smart warehouses don’t just automate tasks—they transform data into actionable insights. The integration of WMS and WCS provides real-time monitoring of every warehouse operation, enabling managers to make informed decisions quickly.

Key advantages include:

l Inventory Accuracy: Every movement of goods is tracked, reducing discrepancies and stockouts.

l Predictive Maintenance: Equipment data is continuously monitored to identify potential failures before they occur, minimizing downtime.

l Performance Analytics: Real-time dashboards help track throughput, identify bottlenecks, and optimize workflow patterns.

By turning operational data into actionable insights, businesses gain the flexibility to respond instantly to market demands, seasonal peaks, or urgent customer orders.

Scalability and Flexibility for Diverse Industries

Every warehouse is unique, and HEGERLS recognizes the need for scalable and adaptable solutions. Our smart warehouse systems are designed to serve industries ranging from e-commerce and retail to automotive, electronics, and pharmaceuticals.

l Modular Design: HEGERLS warehouse systems can be expanded or reconfigured without major downtime, making it easy to grow alongside your business.

l Customized Equipment: Options such as multi-tier shelving, pallet stackers, and automated shuttle racking allow for a tailored solution based on the size and nature of stored goods.

l ERP Integration: Our solutions seamlessly integrate with existing enterprise resource planning (ERP) systems, providing end-to-end visibility across the supply chain.

This level of flexibility ensures that HEGERLS smart warehouses can adapt to evolving business needs, new product lines, or changing logistics strategies.

Improving Safety and Sustainability

Automation doesn’t just boost efficiency—it also enhances safety and sustainability. HEGERLS smart warehouses are equipped with advanced monitoring systems and intelligent control features to maintain a safe and eco-friendly working environment.

l Collision Avoidance and Safety Sensors: Automated shuttles and conveyors are equipped with sensors to prevent accidents and ensure safe interaction with human operators.

l Optimized Energy Use: Intelligent scheduling and motion control reduce unnecessary energy consumption, lowering operational costs and environmental impact.

l Ergonomic Design: By reducing manual handling of heavy items, HEGERLS systems improve worker safety and reduce injury risk.

Companies benefit from both operational efficiency and a safer, more sustainable warehouse environment, which aligns with global sustainability goals.

Real-World Applications and Success Stories

HEGERLS WMS & WCS integration has already transformed warehouses worldwide. Some notable examples include:

E-commerce Fulfillment Centers: Using four-way shuttle systems and ASRS, order processing times have been reduced by up to 40%, with minimal human intervention.

Automotive Spare Parts Distribution: Just-in-time delivery has been optimized with dynamic inventory management, ensuring critical parts are always available.

Pharmaceutical Warehouses: Temperature-controlled storage is monitored and adjusted in real-time, maintaining compliance with stringent regulatory requirements.

These success stories highlight the versatility and effectiveness of HEGERLS smart warehouse solutions across industries.

Future-Ready Warehousing

As supply chains become more complex and customer expectations rise, the demand for intelligent warehouse automation will continue to grow. HEGERLS is committed to staying at the forefront of innovation, integrating new technologies such as:

l Artificial Intelligence (AI): For predictive analytics, route optimization, and intelligent task allocation.

l IoT Connectivity: To enable real-time equipment monitoring and data-driven decision-making.

l Robotics and AGVs: To expand automated material handling capabilities, particularly in high-density or hazardous storage areas.

By embracing these innovations, HEGERLS ensures that its clients’ warehouses are future-ready, scalable, and capable of handling the evolving demands of global supply chains.

About HEGERLS

HEGERLS is a leading provider of intelligent warehouse solutions, offering comprehensive automation systems that combine innovation, reliability, and scalability. With a focus on automation, data-driven management, and safety, HEGERLS empowers businesses worldwide to:

l Increase operational efficiency

l Reduce costs

l Improve inventory accuracy

l Achieve scalable growth

Our solutions are trusted by businesses across Europe, North America, Asia, and the Middle East, enabling clients to streamline their operations and achieve operational excellence in today’s competitive market.

Key Features of HEGERLS Smart Warehouses

l Integrated WMS & WCS: Real-time data synchronization and equipment coordination.

l Four-Way Shuttle Systems & ASRS: Continuous, high-speed storage and retrieval.

l Modular and Scalable Design: Easily expandable as business requirements grow.

l ERP Compatibility: Full supply chain visibility and control.

l Safety & Sustainability Features: Collision avoidance, energy optimization, and ergonomic designs.

Conclusion

The integration of WMS and WCS in HEGERLS smart warehouses represents a major leap forward in warehouse automation and operational efficiency. By combining advanced software, automated material handling, and real-time data management, HEGERLS enables businesses to meet today’s challenges while preparing for the future.

For companies seeking a scalable, flexible, and intelligent warehousing solution, HEGERLS provides the tools, technology, and expertise to transform traditional warehouses into high-performance smart facilities.

Ready to transform your warehouse? Get a personalized quote based on your unique operational needs.