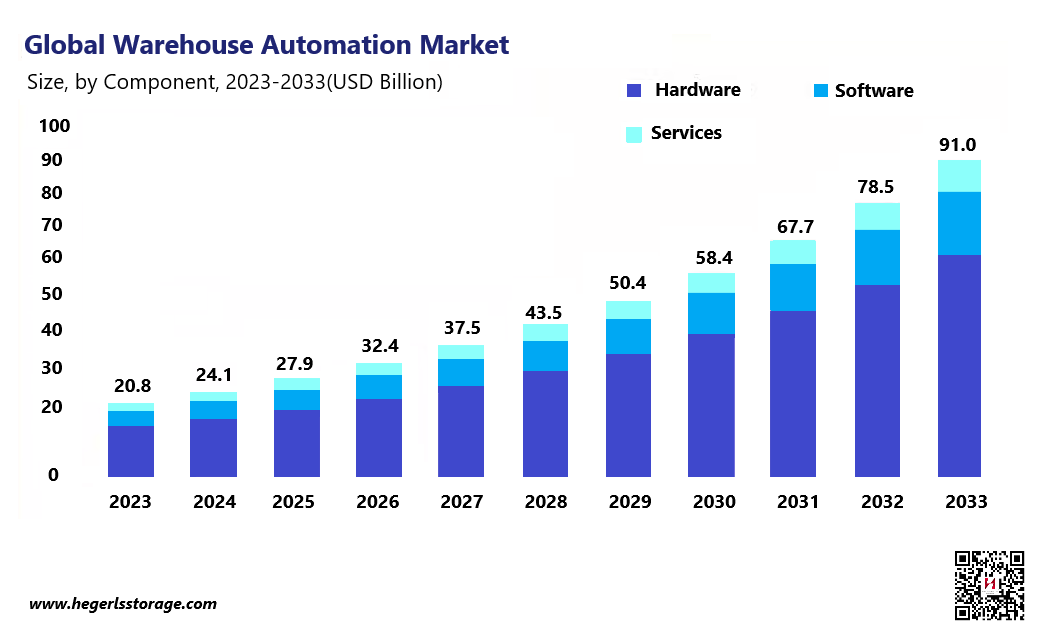

[Hebei, China — October 2025] — Recent reports illustrate both the huge opportunity and significant challenges in warehouse automation. On one hand, the Warehouse Automation Market is projected to reach USD 91.0 billion by 2033, growing from about USD 20.8 billion in 2023 with a CAGR of ~15.9%. On the other hand, adoption is constrained: deploying mobile robots across a whole warehouse can cost ~USD 1 million, and many companies identify cost / budget constraints as a top barrier.

This dual reality — high growth potential and high entry cost — defines the competitive landscape for automation providers. HEGERLS, with its combination of hardware and software (including CC-WMS, YUNTU-WCS), is positioned to help bridge that gap.

Market Growth: Size, Drivers & Segments

Massive market scale & growth

According to Market.US, the warehouse automation market is expected to expand from USD 20.8 billion in 2023 to USD 91.0 billion by 2033, a CAGR of ~15.9%.

Hardware dominance, but software & service uptick

In 2023, hardware (robotics, AS/RS, conveyors) captured over 70% of the market.

Industry & region drivers

Retail & e-commerce represent ~33.5% of demand, pushing need for faster fulfillment. North America leads, but Asia-Pacific shows strong growth.

U.S. market outlook

The U.S. alone generated ~USD 5,777.7 million in 2024 and is projected to reach USD 16,602.6 million by 2030 (CAGR ~20.6%).

These figures highlight not only the size of the opportunity, but also that demand is shifting from just hardware to integrated systems, software, and services.

Cost & ROI: The Primary Adoption Barriers

While the market outlook is strong, many potential customers hesitate due to cost and risk:

Deploying mobile robots across a warehouse can cost around USD 1 million on average.

One-third of respondents in tracking surveys cite budget constraints as the main reason to delay or avoid adoption.

Even with strong growth projections for mobile robots (e.g. ~20% annual growth), macroeconomic factors, retail corrections, and cautious capital spending have dampened some forecasts.

The adoption curve is less “hockey-stick” than previously expected; many firms are opting for gradual automation rather than full-scale robotic rollouts.

Thus, while opportunity is large, effective strategies must account for pragmatism, phased deployment, risk management, and clear ROI modeling.

HEGERLS Perspective: Opportunities and Response Strategies

HEGERLS sees these challenges as opportunities for differentiation and innovation. Key strategies include:

Barrier | HEGERLS Response / Solution |

High upfront cost | • Offer modular systems with phased rollout, allowing clients to automate gradually. • Optimize design for cost per pallet position using high-density solutions (four-way or six-way shuttles). • Use rack-supported warehouse structures to reduce building modification costs. |

Long ROI period | • Emphasize energy efficiency, maintenance optimization, and equipment lifespan to shorten payback time. • Implement IoT sensors to monitor performance and reduce downtime. |

Budget uncertainty | • Explore financing, leasing, or Robotics-as-a-Service (RaaS) models to lower entry barriers. • Provide cost-benefit analysis including labor savings, space efficiency, and error reduction. |

Customer confidence & risk | • Showcase case studies (India cold chain project, Russia spare parts warehouse). • Provide digital twin simulations for pre-deployment validation. |

HEGERLS Products Addressing Cost & ROI Challenges

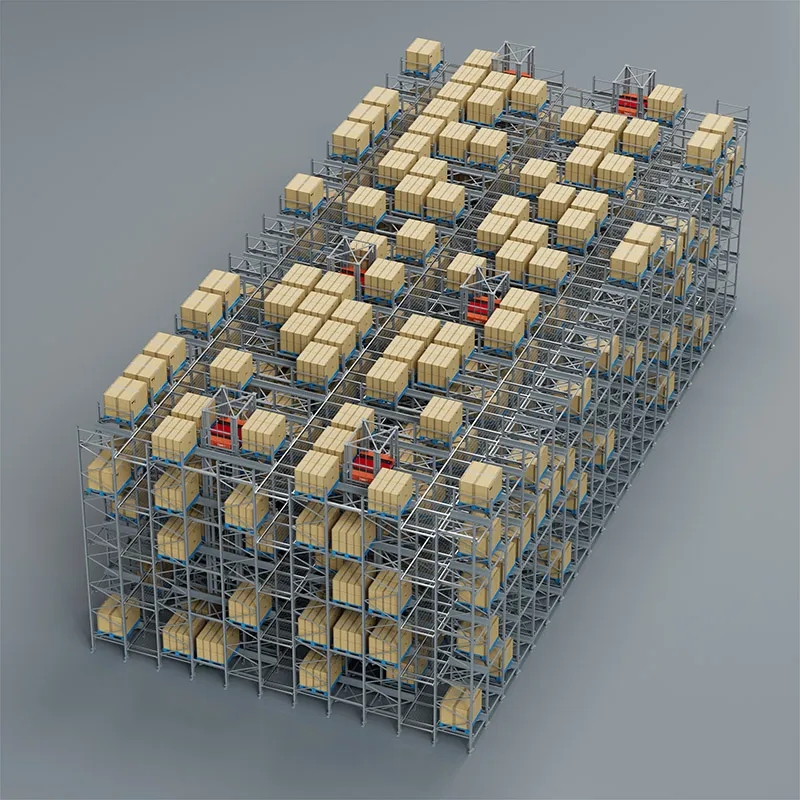

Two-Way Shuttles: Cost-effective, directional aisle automation for mid-size warehouses, ideal as an initial automation step.

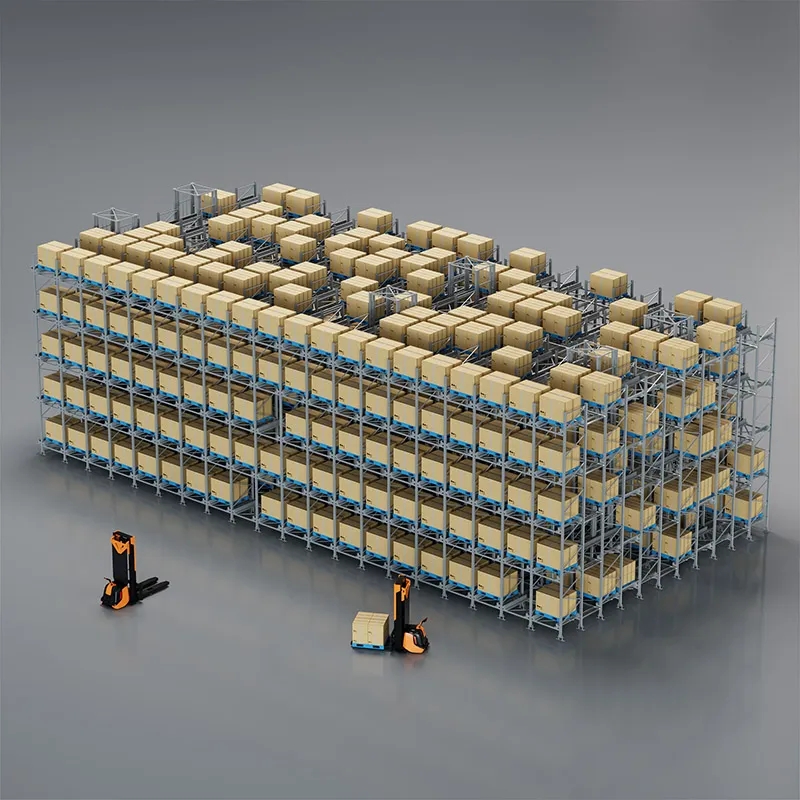

Four-Way Shuttles: High-density, multi-directional pallet movement, suitable for cold storage and bulk warehouses.

Six-Way Shuttles: Maximum directional and vertical flexibility for fully automated high-density storage.

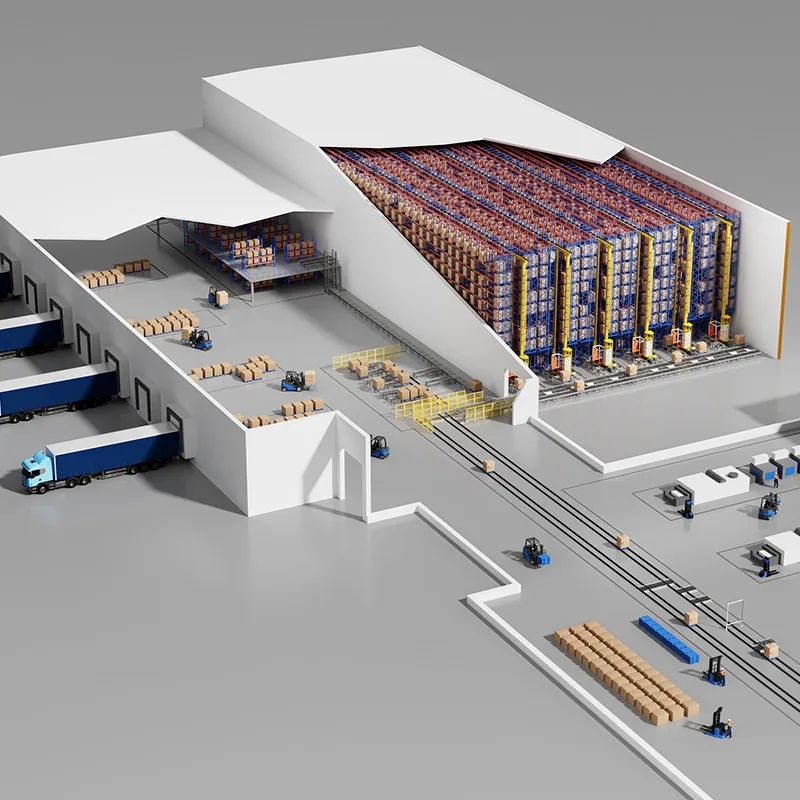

Stacker Crane Systems (AS/RS): High vertical reach and precision for industrial spare parts and heavy-duty applications.

Rack-Supported Warehouses & Mobile Racking Systems: Maximize space efficiency and reduce building/renovation costs.

Drive-In Racking: Ideal for bulk homogeneous goods, reducing aisle requirements and associated costs.

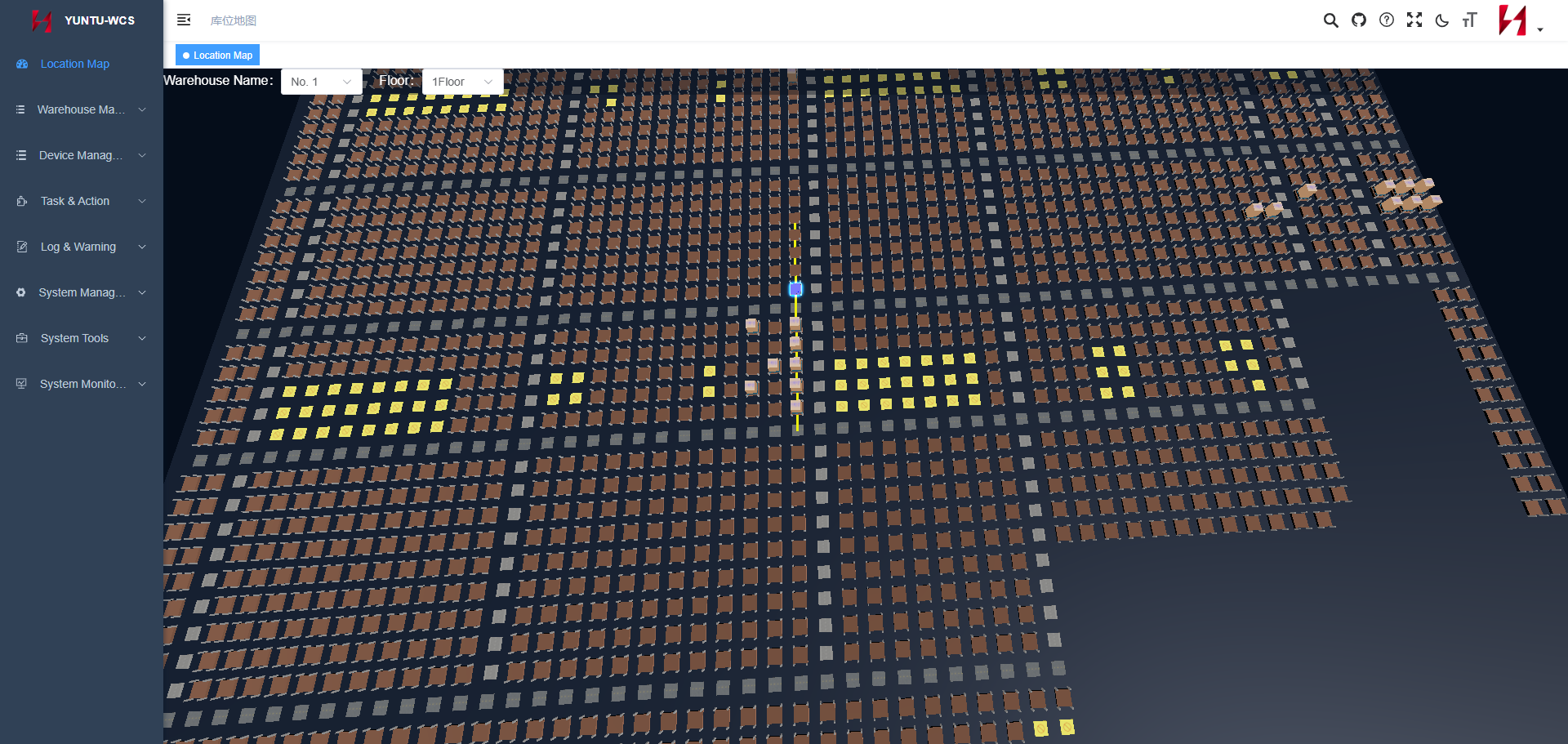

CC-WMS & YUNTU-WCS: HEGERLS integrates high-density storage hardware with advanced software management systems to deliver complete automation packages, which enables real-time inventory visibility, optimized slotting and order picking, predictive equipment monitoring and faster ROI through higher throughput and density

Recommendations for Companies Evaluating Automation

Conduct a detailed cost model — Include upfront investment, operational expenses (energy, cooling, maintenance, training), labor savings, and anticipated downtime.

Start small, scale gradually — Begin with selected use cases, such as pallet movement or picking assistance, and expand over time.

Select modular, scalable equipment — Ensure future upgrades or expansions remain cost-effective.

Choose vendors with proven support and maintenance — Reliable after-sales service ensures long-term system stability.

Explore flexible financing options — Leasing, phased payments, or RaaS can lower initial financial barriers.

Conclusion

Warehouse automation and mobile robotics have tremendous market potential, but cost and ROI remain the key decision points for adoption. HEGERLS understands these challenges and continues to innovate across product design, service models, and project delivery, helping clients reduce investment risk, lower total cost of ownership, and accelerate ROI.

For companies considering warehouse automation or robot systems, HEGERLS offers custom ROI modeling, phased deployment plans, and complete end-to-end solutions from hardware to software and maintenance support.

Contact HEGERLS today to explore how we can help optimize your warehouse efficiency and ROI.

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955