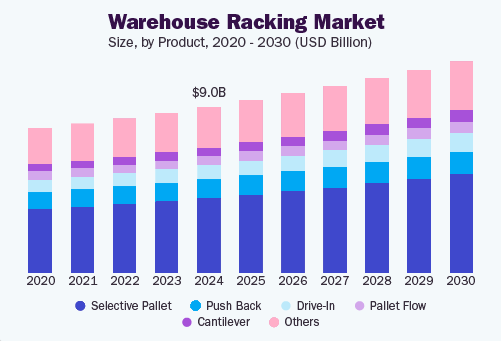

[Hebei, China – September 2025] – According to the latest Grand View Research report, the global warehouse racking market was valued at approximately USD 9.71 billion in 2024 and is projected to grow to USD 12.41 billion by 2030, at a compound annual growth rate (CAGR) of about 4.2%.

Below are some key market dynamics, challenges, and how HEGERLS is aligned to capitalize on these trends.

Key Market Trends & Drivers

1.Demand for warehouse space and systematic storage

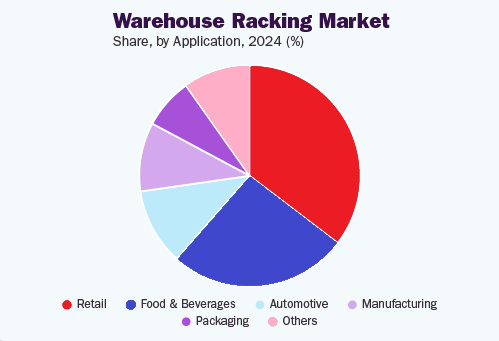

As global e-commerce, retail, manufacturing, food & beverage industries expand, there's increased demand for optimized storage solutions—increasing capacity, easier material handling, faster retrieval.

2.Selective pallet racking remains dominant

The selective pallet racking held the largest share (~45%) in 2024 and is expected to keep growing strongly. Its value is in easy accessibility and flexibility.

3.Rising adoption of specialized racking types like cantilever

Cantilever racking is one of the fastest-growing product segments, especially for items with varying lengths, weights, or odd shapes (e.g. pipes, long planks).

Drive-in racking is also widely adopted for high-density storage of homogeneous goods, especially in cold storage and food & beverage sectors, due to its space utilization efficiency.

4.Regional growth dynamics

North America leads the market in revenue share (~27.8% in 2024).

Asia-Pacific is one of the fastest growing regions, driven by rising online retail, industrialization, and logistics infrastructure expansions.

5.Focus on automation, safety, and advanced technologies

Warehouse operators increasingly demand racking systems integrated with automation, smart warehouse management, collision / earthquake resistance, reliable steel construction, and safety features.

Challenges & Restraints

High upfront investment for steel racking, especially for high-capacity and specialized systems.

Space constraints in densely populated or urban warehouse locations make maximizing height, density, and efficient layouts more important.

Regulatory and safety requirements (inspections, load capacities, seismic/collision impact) that must be met, increasing design and maintenance costs.

Skill and knowledge gaps in some markets for using or maintaining advanced racking and automated systems.

HEGERLS’s Strategic Alignment & Opportunities

Based on these trends, here's how HEGERLS is positioned, and where we see strong opportunity:

Product portfolio match

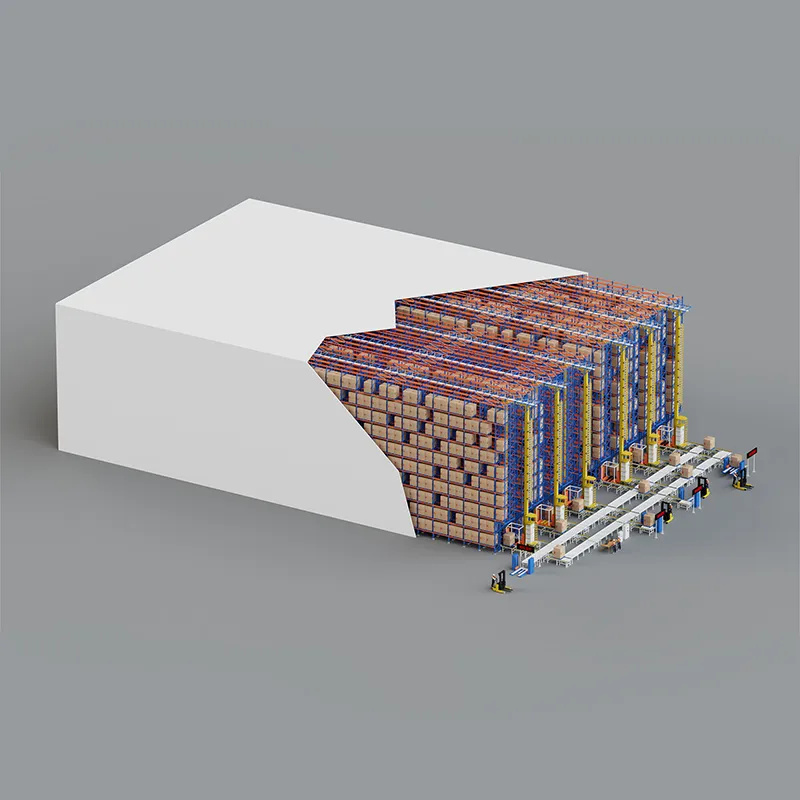

HEGERLS already offers or can offer systems like selective pallet racking, four-way shuttle systems, AS/RS (stacker cranes), rack-supported warehouse systems. These align well with market demand for high‐density, flexible access, automation, and cold chain compatible storage.

Focus on specialized applications

Projects like cold storage (−22 °C), or spare-parts warehouses for heavy machinery (stacker crane systems) are exactly where demand for robust, reliable racking with safety, durability, and precise control is rising.

Customization & integration

As safety, regional regulatory requirements, automation integration become more critical, HEGERLS can differentiate by offering tailored designs (e.g. seismic-resistant racks, collision-resistant features), integration with warehouse control systems, sensors, robotics.

Geographical growth

In Asia-Pacific, especially India, China, Southeast Asia, there's strong growth in logistics, cold chain, e-commerce. HEGERLS can expand in these regions leveraging local partnerships, adapting to regional code/standards. Also in Middle East & Africa, market expansion driven by industrialization and retail/distribution infrastructure.

Sustainability & material innovation

Using durable steel racking systems is standard; there’s upward pressure for lighter weight but strong materials, possibly recycled steel, coatings, green designs (e.g., energy-efficiency, minimal material waste). HEGERLS may explore these to attract environmentally conscious customers.

Four-way Shuttle System

6 Way Pallet Shuttle System for High-Density Smart Warehousing

Rack Supported Warehouse

Implications & Next Steps for HEGERLS

R&D / Engineering investment in enhanced designs: e.g., modular rack supported warehouses, racks for extreme cold, systems with built-in monitoring for load / safety.

Automation & digital integration: Smart warehouse software, sensors, AS/RS compatibility, warehouse control systems to optimize picking / retrieval times, safety, space utilization.

Strengthen safety & compliance capabilities, offering features such as collision-resistance, seismic resistance, regular inspection services, training for clients in maintaining racks safely.

Market expansion strategies, especially in Asia-Pacific and emerging markets, emphasizing cost-efficient yet high-quality systems, possibly localizing production or supply chain for cost advantage.

HEGERLS’s engineering expertise and customization capabilities allow us to meet industry needs for safety, efficiency, and automation integration.

Looking Ahead

The warehouse racking market is steadily expanding, and HEGERLS is ready to seize this momentum by delivering innovative, reliable, and intelligent warehousing solutions tailored to global industries.

Discover how HEGERLS can optimize your storage operations. Contact Us Today!

Contact Info

Website: https://www.hegerlsstorage.com/

Email: hegerls1@hegerlsstorage.com

Phone: +86-311-87240955